Abstract

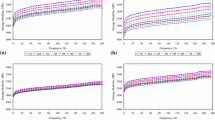

The mechanical behavior of heat-treated spruce wood was investigated in relation to the mass loss that occurs during thermal treatment. At constant wood moisture content, the strength, failure strain and toughness of wood were reduced by the heat-bath treatment, decreasing with increasing mass loss. The stiffness was unaffected up to a mass loss of about 3%, and thereafter it decreased. The mechanical properties, however, are not only dependent on the mass loss but also on the relative humidity in the heating atmosphere. As a function of mass loss, the inelastic ductility and the inelastic toughness were the lowest when wood was heated in a dry climate, as compared to a moist climate.

On the other hand, the mechanical properties of heat-treated wood were tested at constant ambient humidity. In such circumstances, the failure strain and the toughness were still reduced, but the strength and the stiffness were actually improved up to a mass loss of about 2%–3%. The improvement is due to the lower equilibrium moisture content of heat-treated wood when placed in service conditions. As a function of mass loss, wood heated at intermediate relative humidity (in the vicinity of 50%) exhibited the best mechanical behavior, which surprisingly included inelastic ductility. This is believed to be due to some irreversible hydrogen bonding.

Zusammenfassung

Das mechanische Verhalten von wärmebehandeltem Fichtenholz wurde in Zusammenhang mit dem bei der Wärmebehandlung auftretenden Masseverlust untersucht. Durch die Wärmebadbehandlung nahmen die Festigkeit, Bruchdehnung und Zähigkeit bei konstanter Holzfeuchte mit zunehmendem Masseverlust ab. Die Steifigkeit nahm erst ab einem Masseverlust von ungefähr 3% ab. Die mechanischen Eigenschaften hängen jedoch nicht nur vom Masseverlust ab, sondern auch von der relativen Luftfeuchte bei der Wärmebehandlung. Bezogen auf den Masseverlust waren der nicht elastische Anteil der Bruchdehnung und der nicht elastische Anteil der Zähigkeit bei Holz, das in trockenem Klima wärmebehandelt wurde, niedriger als bei einer Behandlung in feuchtem Klima.

Daneben wurden die mechanischen Eigenschaften von wärmebehandeltem Holz bei konstanter Luftfeuchte untersucht. Unter diesen Bedingungen nahmen Bruchdehnung sowie Zähigkeit ebenfalls ab, jedoch verbesserte sich die Festigkeit und Steifigkeit bis zu einem Masseverlust von 2%–3%. Dies ist auf die niedrigere Gleichgewichtsfeuchte von wärmebehandeltem Holz unter Praxisbedingungen zurückzuführen. Bezogen auf den Masseverlust zeigte Holz, das bei mittlerer relativer Luftfeuchte (ca. 50%) wärmebehandelt wurde, die besten mechanischen Eigenschaften. Erstaunlicherweise gilt dies auch für den nicht elastischen Anteil der Bruchdehnung, was wahrscheinlich auf irreversible Wasserstoffbindungen zurückzuführen ist.

Similar content being viewed by others

References

Alén R, Kotilainen R, Zaman A (2002) Thermochemical behavior of Norway spruce (Picea abies) at 180–225 °C. Wood Sci Technol 36:163–171

Back EL, Salmén NL (1982) Glass transitions of wood components hold implications for molding and pulping processes. Tappi 65:107–110

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Borrega M, Kärenlampi P (2007) Hygroscopicity of heat-treated spruce wood. In: Proceedings of the Nordic Workshop in Wood Engineering, WoodTech Sweden, Skellefteå

Bourgois J, Guyonnet R (1988) Characterization and analysis of torrified wood. Wood Sci Technol 22:143–155

Edvardsen K, Sandland KM (1999) Increased drying temperature – Its influence on the dimensional stability of wood. Holz Roh- Werkst 57:207–209

Esteves B, Velez Marques A, Domingos I, Pereira H (2007) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 41:193–207

Gerhards CC (1982) Effect of moisture content and temperature on the mechanical properties of wood: an analysis of immediate effects. Wood Fiber 14:4–36

Haygreen JG, Bowyer JL (1996) Forest Products and Wood Science: An Introduction. Iowa State University Press, Ames, Iowa, pp 213–242

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh- Werkst 60:1–6

Kubojima Y, Okano T, Ohta M (2000) Bending strength and toughness of heat-treated wood. J Wood Sci 46:8–15

Militz H (2002) Heat treatment technologies in Europe: scientific background and technological state-of-art. In: Proceedings of conference on “Enhancing the durability of lumber and engineered wood products”. Kissimmee, Orlando. Forest Products Society, Madison, US

Obataya E, Shibutani S, Hanata K, Doi S (2006) Effects of high temperature kiln drying on the practical performance of Japanese cedar wood (Cryptomeria japonica). II: Changes in mechanical properties due to heating. J Wood Sci 52:111–114

Poncsák S, Kocaefe D, Bouazara M, Pichette A (2006) Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci Technol 40:647–663

Santos JA (2000) Mechanical behaviour of Eucalyptus wood modified by heat. Wood Sci Technol 34:39–43

Stamm AJ, Burr HK, Kline AA (1946) Staybwood…Heat-stabilized wood. Ind Eng Chem 38:630–634

Stone JE (1955) The rheology of cooked wood. II: Effect of temperature. Tappi 38:452–459

Sweet MS, Winandy JE (1999) Influence of degree of polymerization of cellulose and hemicellulose on strength loss in fire-retardant-treated southern pine. Holzforschung 53:311–317

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh- Werkst 56:149–153

Weiss HF (1921) Method and apparatus for transforming wood. Patent US1366225

Winandy JE, Lebow PK (2001) Modeling strength loss in wood by chemical composition. Part 1. An individual component model for southern pine. Wood Fiber Sci 33:239–254

Zaman A, Alén R, Kotilainen R (2000) Thermal behavior of Scots pine (Pinus sylvestris) and silver birch (Betula pendula) at 200–230 °C. Wood Fiber Sci 32:138–143

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borrega, M., Kärenlampi, P.P. Mechanical behavior of heat-treated spruce (Picea abies) wood at constant moisture content and ambient humidity . Holz Roh Werkst 66, 63–69 (2008). https://doi.org/10.1007/s00107-007-0207-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-007-0207-3