Abstract

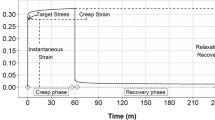

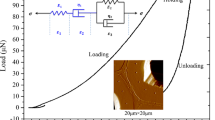

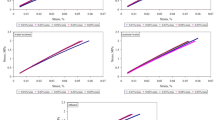

Viscoelasticity of air-dried or thermo-treated Cedrus deodara and Alnus cordata has been evaluated by means of Dynamic Mechanical Analysis (DMA) in the bending mode at 30 °C. E1, E2 and tanδ have been investigated by frequency-strain spectra. Mechanical properties have been explored by means of creep, stress-relaxation experiments and stress–strain plots at different strain-rates. Relaxation times and Young’s modulus E have been evaluated. The morphology of the samples has been examined by means of optical microscopy. Rheological differences either among air-dried woods, or between air-dried and thermo-treated woods, have been observed. In particular, air-dried wood (and especially Cedrus) shows a significant plastic behaviour. In contrast, the thermo-treatment makes the materials mainly elastic and structurally stable. The plasticity of the air-dried woods seems to be due to the shear of the hemicellulose interface and to plasticizers of lignin matrix; the increased elasticity of the thermo-treateds would be due to the additional lignin cross-linking, and loss of hemicellulose and plasticizers. Air-dried woods, especially the softwood, have a thermoplastic-like behaviour, where the non-bonded intermolecular interactions prevail, in contrast, the thermo-treated woods are thermosetting-like due to the higher degree of cross-link of the polymeric matrix. The study demonstrates the possibility of characterizing wood through viscoelasticity and dynamic mechanical analysis.

Similar content being viewed by others

References

Havimo M (2009) A literature-based study on the loss tangent of wood in connection with mechanical pulping. Wood Sci Technol 43:627

Stanciu MD, Curtu I, Grimberg R, Savin A (2013) Research regarding the complex modulus determined with dynamic mechanical analysis (DMA) in case of beech (Fagus Silvatica L.) and alder (Alnus Glutinosa Gaertn). Pro Ligno 9:587

Fabiyi JS, Ogunleye BM (2015) Mid-infrared spectroscopy and dynamic mechanical analysis of heat-treated obeche (Triplochiton scleroxylon) wood, Maderas. Ciencia y tecnología 17(1):5–16. doi:10.4067/S0718-221X2015005000001

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4:370

Heitner C, Dimmel D, Schmidt J (2010) Lignin and lignans: advances in chemistry. CRC Press, Boca Raton

Kelley SS, Rials TG, Glasser WG (1987) Relaxation behaviour of the amorphous components of wood. J Mater Sci 22:617

Olsson A, Salmén L (2004) The softening behavior of hemicelluloses related to moisture. In: Gatenholm P, Tenkanen M (eds) Hemicelluloses: science and technology. American Chemical Society, Washington, pp 184–197

Entwistle KM (2005) The mechanosorptive effect in Pinus radiate. D Don Holzforschung 59:552

Brémaud I, Ruelle J, Thibaut A, Thibaut B, Harris PJ (2013) Changes in viscoelastic vibrational properties between compression and normal wood: roles of microfibril angle and of lignin. Holzforschung 67:75

Sharma M, Brennan M, Chauhan SS, Entwistle KM, Altaner CM, Harris PJ (2015) Wood quality assessment of Pinus radiata (radiata pine) saplings by dynamic mechanical analysis. Wood Sci Technol 49:1239

Habibi MK, Tam LH, Lau D, Lu Y (2016) Viscoelastic damping behavior of structural bamboo material and its microstructural origins. Mech Mater 97:184

Fengel D, Wegener G (2003) Wood, chemistry, ultrastructure and reactions. Verlag, Berlin

Demaree LA, Erickson RW (1975) The temperature dependent effect of extractive content on redwood shrinkage. Sci. Jour. Ser. Paper No. 9096 of the Univ. of Minn. Agr. Exp. Sta.

Hakeem KR, Jawaid M, Alothman O (2015) Agricultural biomass based potential materials. Springer, Berlin

Lisperguer J, Droguett C, Ruf B (2009) Viscoelastic properties of Pinus Radiata acetylated wood. Wood Research 54:31

Obataya E, Umezawa T, Nakatsubo F, Norimoto M (1999) The effects of water soluble extractives on the acoustic properties of reed (Arundo donax L.). Holzforschung 53:63

Brémaud I, Amusant N, Minato K, Gril J, Thibaut B (2013) Effect of extractives on vibrational properties of African Padauk (Pterocarpus soyauxii Taub.). Wood Sci Technol 45:461

Wood Handbook (2010) Wood as an engineering material. Forest Products Society, Peachtree Corners

Birkinshaw C, Buggy M, Henn GG (1986) Dynamic mechanical analysis of wood. J Mater Sci Lett 5:898

Ravve A (2013) Principles of polymer chemistry. Springer Science & Business Media, Berlin

Ferrari S, Allegretti O, Cuccui I, Sandak J, Sandak A (2012) Thermo-vacuum process for wood thermal modification: results for some European softwood and hardwood species treated at different conditions, European Conference on Wood Modification

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz als Roh- und Werkstoff 56:149

Nardi Berti R (2006) La struttura anatomica del legno e il riconoscimento dei legnami italiani di più corrente impiego. CNR-IVALSA, Firenze

Acknowledgments

We thank the anonymous referees for their precious suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Villani, V., Pucciariello, R. & Lavallata, V. Viscoelasticity of Air-Dried or Thermo-Treated Woods. J Polym Environ 25, 479–486 (2017). https://doi.org/10.1007/s10924-016-0809-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0809-0