Abstract

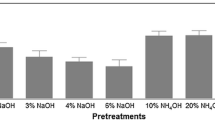

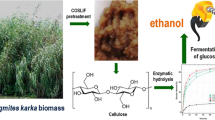

Pennisetum purpureum, commonly known as elephant grass, possesses an immense ability to be recognized as bioenergy crop due to its high carbohydrate content and ample availability in the northeastern states of India. In the present study, an alkaline treatment was conducted using NaOH of different concentrations (1%, 2% and 3% (w/v)) at varying reaction periods of 30, 60 and 90 min with an aspiration of maximum delignification and an enhanced recovery of carbohydrates from biomass. A maximum delignification of 81.0% (w/w) was obtained when the biomass was pretreated with 2% (w/v) of NaOH for 60 min while in the presence of 3% (w/v) of NaOH, the highest cellulose recovery of 72.3% (w/w) was accounted at 90 min of reaction time. During saccharification of biomass, a maximum 18.4 g/L of glucose was produced using 20 filter paper unit of commercial cellulase after 48 h of enzymatic reaction with a cellulose conversion of more than 46%. Furthermore, product inhibition study showed the significant inhibitory effect on enzymatic production of sugars even in the presence of 2 g/L glucose and xylose in the reaction system. The severity of alkaline treatment of the untreated and treated biomass was evaluated using different physiochemical analyses. Moreover, the extracted lignin obtained after acid precipitation of alkaline filtrate was characterised using UV-Visible spectrophotometer. Finally, two-way ANOVA revealed a significant variation in the production of glucose and xylose from biomass even when glucose was added at a fixed concentration (P value = 0.00044 << 0.05) into the reaction system. On the other hand, xylose shows significant inhibition in glucose and xylose production from biomass at both of a particular (P value = 9.05 × 10−7 << 0.05) and different (P value = 0.0078 << 0.05) concentrations of extraneous addition.

Similar content being viewed by others

References

Ascencio JJ, Chandel AK, Philippini RR, Silva SS (2019) Comparative study of cellulosic sugars production from sugarcane bagasse after dilute nitric acid, dilute sodium hydroxide and sequential nitric acid-sodium hydroxide pretreatment. Biomass Conv Bioref. https://doi.org/10.1007/s13399-019-00547-6

Guarneros-Flores J et al (2019) Maximization of fermentable sugar production from sweet sorghum bagasse (dry and wet bases) using response surface methodology (RSM). Biomass Convers Biorefin 9:633–639

Wang S et al (2017) Ultrasound assisted alkaline pretreatment to enhance enzymatic saccharification of grass clipping. Energy Convers Manag 149:409–415

Xie X et al (2018) A sustainable and effective potassium hydroxide pretreatment of wheat straw for the production of fermentable sugars. Bioresour Technol Rep 3:169–176

Ajjan FN et al (2016) High performance PEDOT/lignin biopolymer composites for electrochemical supercapacitors. J Mater Chem A 4:1838–1847

Song K, Chu Q, Hu J, Bu Q, Li F, Chen X, Shi A (2019) Two-stage alkali-oxygen pretreatment capable of improving biomass saccharification for bioethanol production and enabling lignin valorization via adsorbents for heavy metal ions under the biorefinery concept. Bioresour Technol 276:161–169

Haldar D, Purkait MK (2020) Lignocellulosic conversion into value-added products: a review. Process Biochem 89:110–133

Ji H et al (2018) Valorization of lignocellulosic biomass toward multipurpose fractionation: furfural, phenolic compounds, and ethanol. ACS Sustain Chem Eng 6:15306–15315

Haldar D, Sen D, Gayen K (2018) Enzymatic hydrolysis of banana stems (Musa acuminata): optimization of process parameters and inhibition characterization. Int J Green Energy 15:406–413

Basso V et al (2014) Different elephant grass (Pennisetum purpureum) accessions as substrates for enzyme production for the hydrolysis of lignocellulosic materials. Biomass Bioenergy 71:155–161

Pensri B et al (2016) Potential of fermentable sugar production from Napier cv. Pakchong 1 grass residue as a substrate to produce bioethanol. Energy Procedia 89:428–436

Phitsuwan P, Sakka K, Ratanakhanokchai K (2016) Structural changes and enzymatic response of Napier grass (Pennisetum purpureum) stem induced by alkaline pretreatment. Bioresour Technol 218:247–256

Eliana C et al (2014) Effects of the pretreatment method on enzymatic hydrolysis and ethanol fermentability of the cellulosic fraction from elephant grass. Fuel 118:41–47

Minmunin J, Limpitipanich P, Promwungkwa A (2015) Delignification of elephant grass for production of cellulosic intermediate. Energy Procedia 79:220–225

Bensah EC, Kádár Z, Mensah MY (2019) Alkali and glycerol pretreatment of West African biomass for production of sugars and ethanol. Bioresour Technol Rep 6:123–130

Segal L et al (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Dil EA et al (2016) Application of artificial neural network and response surface methodology for the removal of crystal violet by zinc oxide nanorods loaded on activate carbon: kinetics and equilibrium study. J Taiwan Inst Chem Eng 59:210–220

Roosta M, Ghaedi M, Daneshfar A, Darafarin S, Sahraei R, Purkait MK (2014) Simultaneous ultrasound-assisted removal of sunset yellow and erythrosine by ZnS:Ni nanoparticles loaded on activated carbon: optimization by central composite design. Ultrason Sonochem 21:1441–1450

Wang Q et al (2015) Cell wall disruption in low temperature NaOH/urea solution and its potential application in lignocellulose pretreatment. Cellulose 22:3559–3568

MacDonald DG et al (1983) Alkali treatment of corn stover to improve sugar production by enzymatic hydrolysis. Biotechnol Bioeng 25:2067–2076

Sharma SK, Kalra KL, Grewal HS (2002) Enzymatic saccharification of pretreated sunflower stalks. Biomass Bioenergy 23:237–243

Kaschuk JJ Santos DdeA, Frollini E, Canduri F, Porto ALM (2019) Influence of pH, temperature, and sisal pulp on the production of cellulases from Aspergillus sp. CBMAI 1198 and hydrolysis of cellulosic materials with different hemicelluloses content, crystallinity, and average molar mass. Biomass Conv Bioref. https://doi.org/10.1007/s13399-019-00440-2

Kataria R, Ghosh S (2014) NaOH pretreatment and enzymatic hydrolysis of Saccharum spontaneum for reducing sugars production. Energ Source Part A 36:1028–1035

Silverstein RA, Chen Y, Sharma-Shivappa RR, Boyette MD, Osborne J (2007) A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour Technol 98:3000–3011

Lima MA et al (2013) Effects of pretreatment on morphology, chemical composition and enzymatic digestibility of eucalyptus bark: a potentially valuable source of fermentable sugars for biofuel production–part 1. Biotechnol Biofuels 6:75

Chen XH et al (2014) Asparagus stem as a new lignocellulosic biomass feedstock for anaerobic digestion: increasing hydrolysis rate, methane production and biodegradability by alkaline pretreatment. B Bioresour Technol 164:78–85

Xu J et al (2010) Sodium hydroxide pretreatment of switchgrass for ethanol production. Energy Fuel 24:2113–2119

Sahoo D, Ummalyma SB, Okram AK, Sukumaran RK, George E, Pandey A (2017) Potential of Brachiaria mutica (Para grass) for bioethanol production from Loktak Lake. Bioresour Technol 242:133–138

Paixao SM et al (2016) Sugarcane bagasse delignification with potassium hydroxide for enhanced enzymatic hydrolysis. RSC Adv 6:1042–1052

McIntosh S, Vancov T (2011) Optimisation of dilute alkaline pretreatment for enzymatic saccharification of wheat straw. Biomass Bioenergy 35:3094–3103

Hu Z, Wen Z (2008) Enhancing enzymatic digestibility of switchgrass by microwave-assisted alkali pretreatment. Biochem Eng J 38:369–378

McIntosh S, Vancov T (2010) Enhanced enzyme saccharification of Sorghum bicolor straw using dilute alkali pretreatment. Bioresour Technol 101:6718–6727

Yanez-S M et al (2014) Physicochemical characterization of ethanol organosolv lignin (EOL) from Eucalyptus globulus: effect of extraction conditions on the molecular structure. Polym Degrad Stab 110:184–194

Binod P et al (2012) Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew Energy 37:109–116

Phitsuwan P et al (2015) Structural features and enzymatic digestibility of Napier grass fibre treated with aqueous ammonia. J Ind Eng Chem 32:360–364

Kristensen JB et al (2008) Cell-wall structural changes in wheat straw pretreated for bioethanol production. Biotechnol Biofuels 1:5

Lu Q-l et al (2014) An investigation on the characteristics of cellulose nanocrystals from Pennisetum sinese. Biomass Bioenergy 70:267–272

Scalbert A et al (1986) Comparison of wheat straw lignin preparations-I. Chemical and spectroscopic characterizations. Holzforschung 40:119–127

Reddy KO, Maheswari CU, Reddy DJP, Rajulu AV (2009) Thermal properties of Napier grass fibers. Mater Lett 63:2390–2392

Acknowledgements

Central Instrumental Facility (CIF) and Centre for the Environment of IIT Guwahati are acknowledged for providing the instrumental facility to perform physicochemical characteristics of the samples.

Funding

This work in financially supported by the MHRD (Ministry of Human Resource and Development; Government of India) through the institute.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haldar, D., Purkait, M.K. Thermochemical pretreatment enhanced bioconversion of elephant grass (Pennisetum purpureum): insight on the production of sugars and lignin. Biomass Conv. Bioref. 12, 1125–1138 (2022). https://doi.org/10.1007/s13399-020-00689-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00689-y