Abstract

The five-carbon sugard-xylose is a major component of hemicellulose and accounts for roughly one-third of the carbohydrate content of many lignocellulosic materials. The efficient fermentation of xylose-rich hemicellulose hydrolyzates (prehydrolyzates) represents an opportunity to improve significantly the economics of large-scale fuel ethanol production from lignocellulosic feedstocks. The National Renewable Energy Laboratory (NREL) is currently investigating a simultaneous saccharification and cofermentation (SSCF) process for ethanol production from biomass that uses a dilute-acid pretreatment and a metabolically engineered strain ofZymomonas mobilis that can coferment glucose and xylose. The objective of this study was to establish optimal conditions for cost-effective seed production that are compatible with the SSCF process design.

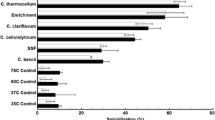

Two-level and three-level full factorial experimental designs were employed to characterize efficiently the growth performance of recombinantZ. mobilis CP4:pZB5 as a function of nutrient level, pH, and acetic acid concentration using a synthetic hardwood hemicellulose hydrolyzate containing 4% (w/v) xylose and 0.8% (w/v) glucose. Fermentations were run batchwise and were pH-controlled at low levels of clarified corn steep liquor (cCSL, 1-2% v/v), which were used as the sole source of nutrients. For the purpose of assessing comparative fermentation performance, seed production was also carried out using a “benchmark” yeast extract-based laboratory medium. Analysis of variance (ANOVA) of experimental results was performed to determine the main effects and possible interactive effects of nutrient (cCSL) level, pH, and acetic acid concentration on the rate of xylose utilization and the extent of cell mass production. Results indicate that the concentration of acetic acid is the most significant limiting factor for the xylose utilization rate and the extent of cell mass production; nutrient level and pH exerted weaker, but statistically significant effects. At pH 6.0, in the absence of acetic acid, the final cell mass concentration was 1.4 g dry cell mass/L (g DCM/L), but decreased to 0.92 and 0.64 g DCM/L in the presence of 0.5 and 1.0% (w/v) acetic acid, respectively. At concentrations of acetic acid of 0.75 (w/v) or lower, fermentation was complete within 1.5 d. In contrast, in the presence of 1.0% (w/v) acetic acid, 25% of the xylose remained after 2 d. At a volumetric supplementation level of 1.5–2.0% (v/v), cCSL proved to be a cost-effective single-source nutritional adjunct that can support growth and fermentation performance at levels comparable to those achieved using the expensive yeast extract-based laboratory reference medium.

Similar content being viewed by others

References

Wright, J. D. (1988),Chem. Eng. Prog. 84, 62–74.

Wright, J. D., Wyman, C. E., and Grohman, K. (1988),Appl. Biochem. Biotechnol. 18, 75–90.

Wyman, C. E. and Hinman, N. D. (1990),Appl. Biochem. Biotechnol. 24/25, 735–753.

Lynd, L. R. (1989),Adv. Biochem. Eng. Biotechnol. 38, 1–52.

Lynd, L. R., Cushman, J. H., Nichols, R. J. and Wyman, C. E. (1991),Science 251, 1318–1323.

Keim, C. R. (1983),Enzyme Microbiol. Technol. 5, 103–114.

Jeffries, T. W. (1981),Biotechnol. Bioeng., Symp. 11, 315–324.

Jeffries, T. W. (1983),Adv. Biochem. Eng. Biotechnol. 27, 1–32.

Jeffries, T. W. (1990), inYeast: Biotechnology and Biocatalysis, Verachtert, H. and De Mot, R., eds., Marcel Dekker, New York, pp. 349–394.

Hahn-Hägerdahl, B., Hallborn, J., Jeppson, H., Olsson, L., Skoog, K., and Walfridson, M. (1993), inBioconversion of Forest and Agricultural Plant Residues Saddler, J. N., ed., C.A.B. International, Wallingford, UK, pp. 231–290.

Hinman, N. D., Wright, J. D., Hoagland, W., and Wyman, C. E. (1989),Appl. Biochem.Biotechnol. 20/21, 391–401.

Hinman, N. D., Schell, D. J, Riley, C. J., Bergeron, P. W., and Walter, P. J. (1992),Appl. Biochem. Biotechnol. 34/35, 639–649.

Lynd, L. R. (1990),Appl. Biochem. Biotechnol. 24/25, 695–719.

Picataggio, S. K., Eddy, C., Deanda, K., Franden, M. A., Finkelstein, M., and Zhang, M. (1996),Seventeenth Symposium on Biotechnology for Fuels & Chemicals (Paper #9).

Picataggio, S. K., Zhang, M., and Finkelstein, M. (1994), in:Enzymatic Conversion of Biomass for Fuels Production, Himmel, M. E., Baker, J. O., and Overend, R. A., eds., American Chemical Society, Washington, DC,ACS Symposium Series 566, pp. 342–362.

Zhang, M., Franden, M. A., Newman, M., McMillan, J., Finkelstein, M., and Picataggio, S. K. (1995),Appl. Biochem. Biotechnol. 51/52, 527–536.

Rogers, P. L., Lee, K. J., Skotnicki, M. L., and Tribe, D. E. (1982),Adv. Biochem. Eng. 23, 37–84.

Lawford, G. R., Lavers, B. H., Good, D., Charley, R., Fein, J., and Lawford, H. G. (1982), inInternational Symposium on Ethanol from Biomass, Duckworth, H. E. and Thompson, E. A., eds., Royal Society of Canada, Winnipeg, Canada, pp. 482–507.

Lawford, H. G. (1988),Proc. VIII Int'l Symp. on Alcohol Fuels, New Energy Development Organization, Tokyo, pp. 21–27.

Swings, J. and DeLey, J. (1977),Bacteriol. Rev. 41, 1–46.

Montenecourt, B.S. (1985), inBiology of Industrial Microorganisms, Demain, A. L. and Simon, N. A., eds., Benjamin/Cummings, Meno Park, CA, pp. 216–287.

Doelle, H. W., Kirk, L., Crittenden, R., Toh, H., and Doelle, M. (1993),Crit. Rev. Biotechnol. 13, 57–98.

Lawford, H. G. (1988),Appl. Biochem. Biotechnol. 17, 203–219.

Lawford, H. G. and Ruggiero, A. (1990),Biotechnol. Appl. Biochem. 12, 206–211.

Bringer, S., Sahm, H., and Swyzen, W. (1984),Biotechnol. Bioeng. Symp. No. 14, 311–319.

Rodriguez, E. and Callieri, D. A. S. (1986),Biotechnol. Lett. 8, 745–748.

Doelle, M. B., Greenfield, P. F., and Doelle, H. W. (1990),Proc. Biochem. 25, 151–156.

Beavan, M., Zawadzki, B., Droiniuk, R., Fein, J. E., and Lawford, H. G. (1989),Appl. Biochem. Biotechnol. 20/21, 319–326.

Lee, G. M., Kim, C. H., Lee, K. J., Zainal Abidin Mohd, Y., Han, M. H., and Rhee, S. K. (1986),J. Ferment Technol. 64, 293–297.

Parekh, S. R., Parekh, R. S., and Wayman, M. (1989),Proc. Biochem. 24, 85–91.

Park, S. C., Kademi, A., and Baratti, J. C. (1993),Biotechnol. Lett. 15(11), 1179–1184.

Liu, C.-Q., Goodman, A. E., and Dunn, N. W. (1988),J. Biotechnol. 7, 61.

Feldman, S. D., Sahm, H., and Sprenger, G. A. (1992),Appl. Microbiol. Biotechnol. 38, 354.

Zhang, M., Eddy, C., Deanda, K., Finkelstein, M., and Picataggio, S. K. (1995),Science 267, 240–243.

Lynd, L. R., Elander, R. T., and Wyman, C. E. (1996),Appl. Biochem. Biotechnol. 57/58, 641–661.

Goodman, A. E., Rogers, P. L., and Skotnicki, M. L. (1982),Appl. Environ. Microbiol. 44(2), 496–498.

Fein, J. E., Charley, R. C., Hopkins, K. A., Lavers, B., and Lawford, H. G. (1983),Biotechnol Lett. 5, 1–6.

Nipkow, A., Beyeler, W., and Feichter, A. (1984),Appl. Microbiol. Biotechnol. 19, 237–240.

Galani, I., Drainas, C., and Typas, M. A. (1985),Biotechnol. Lett. 7, 673–678.

Baratti, J., Varma, R., and Bu'Lock, J. D. (1986),Biotechnol. Lett. 8, 175–180.

Lawford, H. G., Holloway, P., and Ruggiero, A. (1988),Biotechnol. Lett. 10, 809–814.

Lawford, H. G. and Rousseau, J. D. (1996),Appl. Biochem. Biotechnol. 57/58, 307–326.

Asghari, A., Bothast, R. J., Doran, J. B., and Ingram, L. O. (1996),J. Ind. Microbiol. 16, 42–47.

Lawford, H. G. and Rousseau, J. D. (1997),Appl. Biochem. Biotechnol. (18th Symp.),63–65, 287.

Grohman, K., Himmel, M., Rivard, C., Tucker, M., Baker, T., Torget, R., and Graboski, M. (1984),Biotechnol. Bioeng. Symp. 14, 139–157.

Kong, F., Engler, C. R., and Soltes, E. (1992),Appl. Biochem. Biotechnol. 34/35, 23–35.

Timell, T. E. (1964),Adv. Carbohydrate Chem. 19, 247–302.

Lawford, H. G. and Rousseau, J. D. (1993), inEnergy from Biomass and Wastes XVI (March 1992), Klass, D. L., ed., Institute of Gas Technology, Chicago, IL, pp. 559–597.

McMillan, J. D. (1994), inEnzymatic Conversion of Biomass for Fuels Production, Himmel, M. E., Baker, J. O., and Overend, R. A., eds., American Chemical Society, Washington, DC,ACS Symposium Series 566, pp. 411–437.

Lawford, H. G. and Rousseau, J. D. (1993),Appl. Biochem. Biotechnol. 39/40, 301–322.

Lawford, H. G. and Rousseau, J. D. (1994),Appl. Biochem. Biotechnol. 45/46, 437–448.

Box, G. E. P., Hunter, W. G., and Hunter, J. S. (1978), in:Statistics for Experimenters Wiley, New York.

Davies, O. L. (1967), inDesign and Analysis of Industrial Experiments, Hafneri, New York.

Maddox, I. S. and Richert, S. H. (1977),J. Appl. Bacteriol. 43, 197–204.

Myers, R. H. (1971), inResponse Surface Methodology, Allyn and Bacon, Boston.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lawford, H.G., Rousseau, J.D. & McMillan, J.D. Optimization of seed production for a simultaneous saccharification cofermentation biomass-to-ethanol process using recombinantZymomonas . Appl Biochem Biotechnol 63, 269–286 (1997). https://doi.org/10.1007/BF02920430

Issue Date:

DOI: https://doi.org/10.1007/BF02920430