Abstract

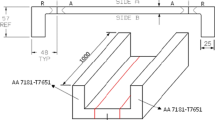

The limiting dome height (LDH) test has been proposed as a simulative test to evaluate the stretch formability of sheet metals which shows good correlation with field forming performance. The present study investigates how deviations from the LDH test procedure and test geometry given in the literature affects the dome test results for aluminum body sheet alloys. The results should be helpful in explaining between-lab variability and helpful to laboratories which cannot perform the LDH test according to specification, because of equipment limitations, in interpreting their data.

Two dome test procedures, both of which are currently being used in R& D departments in the automotive and basic metals industries, were evaluated using four aluminum body sheet alloys. It was found that the procedures gave different numerical results and that the relative formability ratings varied with the procedure used.

The effects of sample thickness and lubrication on dome test results were also studied. A purely geometrical effect of thickness was found, with increasing thickness resulting in higher dome heights at failure. Well-lubricated samples resulted in different formability ratings for the four ABS alloys than do solvent-cleaned samples, accenting the need for dome tests to be performed dry since the ratings from the lubricated tests do not agree with production experience.

It is concluded that before a “best” procedure for performing dome tests can be selected, a correlation study similar to that of Ayres, Brazier, and Sajewski must be performed using both procedures. Cooperative efforts are under way to select and standardize a procedure for dome testing for both the automotive and basic metals industries.

Similar content being viewed by others

References

A. K. Ghosh:Metals Engineering Quarterly, 1975, vol. 15, pp. 53–64.

R. A. Ayres, W.G. Brazier, and V.F. Sajewski:J. Applied Metalworking, 1979, vol. 1 (1), pp. 41–49.

S.S. Hecker: “A Reproducible Cup Test for Assessing Sheet Metal Stretchability,”Metals Engineering Quarterly, 1974, vol. 14, p. 30.

B.S. Levy: Inland Steel Research, private communication to B. S. Shabel, Alcoa, August 24, 1979.

J.M. Story: Alcoa, private communication to W.G. Brazier, Ford Motor Company, June 30, 1980.

M. Chisholm: Reynolds Metals Company, data presented to the American Deep Drawing Research Group, June 18, 1980.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Story, J.M. Variables affecting dome test results. J. Applied Metalworking 2, 119–125 (1982). https://doi.org/10.1007/BF02834209

Issue Date:

DOI: https://doi.org/10.1007/BF02834209