Abstract

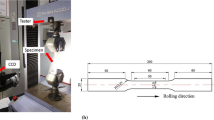

Automotive industries are very much interested in characterization of formability improvement of aluminum alloys at elevated temperatures before designing tools, heating systems, and processing sequences for fabrication of auto-body panels by warm forming technology. In this study, tensile tests of AA5754-H22 aluminum alloy were carried out at five different temperatures and three different strain rates to investigate the deformation behavior correlating with Cowper-Symonds constitutive equation. Laboratory scale warm forming facilities were designed and fabricated to perform limiting dome height and deep drawing tests to evaluate forming limit strains and drawability of sheet metal at different tool temperatures. The forming limit strain and dome height improved significantly when both the die and punch were heated to 200 °C. Remarkable improvement in deep drawn cup depth was observed when die and punch temperatures were maintained at 200 and 30 °C, respectively, producing a non-isothermal temperature gradient of approximately 93 °C across the blank from flange to center. The forming behavior at different isothermal and non-isothermal conditions were predicted successfully using a thermo-mechanical FE model incorporating temperature-dependent properties in Barlat-89 yield criterion coupled with Cowper-Symonds hardening model, and the thinning/failure location in deformed cups were validated implementing the experimental limiting strains as damage model.

Similar content being viewed by others

References

S. Toros, F. Ozturk, and I. Kacar, Review of Warm Forming of Aluminum-Magnesium Alloys, J. Mater. Process. Technol., 2008, 207, p 1-12

V. Psyk, D. Risch, B.L. Kinsey, A.E. Tekkaya, and M. Kleiner, Electromagnetic Forming—A Review, J. Mater. Process. Technol., 2011, 211, p 787-829

S.H. Zhang, Z.R. Wang, Y. Xu, Z.T. Wang, and L.X. Zhou, Recent Developments in Sheet Hydroforming Technology, J. Mater. Process. Technol., 2004, 151, p 237-241

D.V. Wilson, Aluminium Versus Steel in the Family Car—The Formability Factor, J. Mech. Work. Technol., 1988, 16, p 257-277

S. Mahabunphachai, M. Koc, and J.E. Carsley, Investigations on Deformation Behavior of AA5754 Sheet Alloy Under Warm Hydroforming Conditions, J. Manuf. Sci. Eng., 2011, 133, p 051007

J. Jeswiet, M. Geiger, U. Engel, M. Kleiner, M. Schikorra, J. Duflou, R. Neugebauer, P. Bariani, and S. Bruschi, Metal Forming Progress Since 2000, CIRP J. Manuf. Sci. Technol., 2008, 1(2008), p 2-17

R.C. Picu, G. Vincze, F. Ozturk, J.J. Gracio, F. Barlat, and A.M. Maniatty, Strain Rate Sensitivity of the Commercial Aluminum Alloy AA5182-O, Mater. Sci. Eng. A, 2005, 390, p 334-343

P.J. Bolt, R.J. Werkhoven, A.H. Van Den Boogaard, Warm Deep Drawing of Aluminium Sheet, 2003, p 2-9.

F. Ozturk, S. Toros, and H. Pekel, Evaluation of Tensile Behaviour of 5754 Aluminium-Magnesium Alloy at Cold and Warm Temperatures, Mater. Sci. Technol., 2009, 25, p 919-924

D. Li and A. Ghosh, Tensile Deformation Behavior of Aluminum Alloys at Warm Forming Temperatures, Mater. Sci. Eng. A, 2003, 352, p 279-286

M. Jain, J. Allin, and M.J. Bull, Deep Drawing Characteristics of Automotive Aluminum Alloys, Mater. Sci. Eng. A, 1998, 256, p 69-82

S. Yoshihara, K.I. Manabe, and H. Nishimura, Effect of Blank Holder Force Control in Deep-Drawing Process of Magnesium Alloy Sheet, J. Mater. Process. Technol., 2005, 170, p 579-585

G. Palumbo and L. Tricarico, Numerical and Experimental Investigations on the Warm Deep Drawing Process of Circular Aluminum Alloy Specimens, J. Mater. Process. Technol., 2007, 184, p 115-123

H.S. Kim, M. Koç, J. Ni, and A. Ghosh, Finite Element Modeling and Analysis of Warm Forming of Aluminum Alloys—Validation Through Comparisons with Experiments and Determination of a Failure Criterion, J. Manuf. Sci. Eng., 2006, 128, p 613

D.E. Green, K.W. Neale, S.R. MacEwen, A. Makinde, and R. Perrin, Experimental Investigation of the Biaxial Behaviour of an Aluminum Sheet, Int. J. Plast., 2004, 20, p 1677-1706

D. Li and A.K. Ghosh, Biaxial Warm Forming Behavior of Aluminum Sheet Alloys, J. Mater. Process. Technol., 2004, 145, p 281-293

T. Naka, G. Torikai, R. Hino, and F. Yoshida, The Effects of Temperature and Forming Speed on The Forming Limit Diagram for Type 5083 Aluminum-Magnesium Alloy Sheet, J. Mater. Process. Technol., 2001, 113, p 648-653

F. Barlat and K. Lian, Plastic Behavior and Stretchability of Sheet Metals. Part I: A Yield Function for Orthotropic Sheets Under Plane Stress Conditions, Int. J. Plast., 1989, 5, p 51-66

J.W. Yoon, F. Barlat, R.E. Dick, K. Chung, and T.J. Kang, Plane Stress Yield Function for Aluminum Alloy Sheets. Part II: FE Formulation and Its Implementation, Int. J. Plast., 2004, 20, p 495-522

M. Zampaloni, N. Abedrabbo, and F. Pourboghrat, Experimental and Numerical Study of Stamp Hydroforming of Sheet Metals, Int. J. Mech. Sci., 2003, 45, p 1815-1848

T. Naka, Y. Nakayama, T. Uemori, R. Hino, and F. Yoshida, Effects of Temperature on Yield Locus for 5083 Aluminum Alloy Sheet, J. Mater. Process. Technol., 2003, 140, p 494-499

D.G. Tari and M.J. Worswick, Elevated Temperature Constitutive Behavior and Simulation of Warm Forming of AZ31B, J. Mater. Process. Technol., 2015, 221, p 40-55

ASTM, E8/E8M Standard Test Methods for Tension Testing of Metallic Materials, Annu. B. ASTM Stand., 2010, 4(2010), p 1-27

S.K. Panda, D.R. Kumar, H. Kumar, and A.K. Nath, Characterization of Tensile Properties of Tailor Welded IF Steel Sheets and Their Formability in Stretch Forming, J. Mater. Process. Technol., 2007, 183, p 321-332

Livermore Software Technology Corporation, LS-DYNA Keyword User’s Manual, Version 971, California (2007).

R. Courant, Variational Methods for the Solution of Problems of Equilibrium and Vibrations, Bull. Am. Math. Soc., 1943, 49, p 1-23

T. Belytschko, J.I. Lin, and T. Chen-Shyh, Explicit Algorithms for the Nonlinear Dynamics of Shells, Comput. Methods Appl. Mech. Eng., 1984, 42, p 225-251

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 2103-2118

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. London A Math. Phys. Eng. Sci., 1948, 193, p 281-297

J. Winklhofer, G. Trattnig, C. Lind, C. Sommitsch, H. Feuerhuber, F. Barlat, Y.H. Moon, M.G. Lee, Process Simulation of Aluminium Sheet Metal Deep Drawing at Elevated Temperatures, 2010, p 927-934.

N. Abedrabbo, F. Pourboghrat, and J. Carsley, Forming of Aluminum Alloys at Elevated Temperatures - Part 2: Numerical Modeling and Experimental Verification, Int. J. Plast., 2006, 22, p 342-373

P.L. Charpentier, Influence of Punch Curvature on the Stretching Limits of Sheet Steel, Metall. Trans. A, 1975, 6, p 1665-1669

V. Hasek, Research and Theoretical Description Concerning the Influence on the FLDs, Blech Rohre Profile, 1978, 25, p 213-220

Acknowledgment

Authors are thankful to Mr. Chandan Mondal, Metal Forming Laboratory, Department of Mechanical Engineering, IIT Kharagpur for his help while conducting sheet metal forming experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panicker, S.S., Singh, H.G., Panda, S.K. et al. Characterization of Tensile Properties, Limiting Strains, and Deep Drawing Behavior of AA5754-H22 Sheet at Elevated Temperature. J. of Materi Eng and Perform 24, 4267–4282 (2015). https://doi.org/10.1007/s11665-015-1740-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1740-6