Abstract

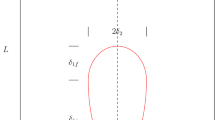

Three-dimensional (3-D) transient temperature variations during autogenous gas tungsten arc welding are determined. The heat diffusion equation is solved using an efficient semidiscrete technique. The model employs a combination of unequally spaced grids concentrated near the moving torch in order to minimize the total number of nodes. Finite differencing is used for the spatial terms. The resulting ordinary differential equations for the transient evolution of thermal transport are solved using the fourth-order Runge-Kutta technique. The temperaturedependent thermal properties and latent heats of phase transformations are accounted for. Computations are carried out for a rectangular parallelepiped with convective and radiative surface thermal conditions. Sample results are presented first for the evolution of thermal profiles during ideal welding conditions. These are next compared with variations obtained due to defects, such as weld track misalignment and inclusions. The potential use of this model in the development of an expert welding system using infrared imagery is indicated.

Similar content being viewed by others

Abbreviations

- Bi:

-

grid Biot number in the coarse zone

- C p :

-

specific heat of the solid based on uniform and constant properties

- Fo:

-

grid Fourier number based on uniform and constant properties

- h :

-

surface heat transfer coefficient

- H :

-

local enthalpy per unit volume in the fine zone

- i :

-

nodal index in thex direction

- j :

-

nodal index in they direction

- k :

-

nodal index in the z direction

- K :

-

material thermal conductivity (subscripted values refer to the fine zone)

- q :

-

volumetric energy generation rate in the fine zone

- q0 :

-

volumetric energy generation rate under the arc center

- Q:

-

energy input rate by the torch into the workpiece

- t :

-

time

- T :

-

local temperature within the workpiece in a coordinate system moving with the arc

- Tinf :

-

ambient temperature

- v x :

-

velocity component of torch motion in thex direction during misalignment referenced to a fixed coordinate system

- v y :

-

velocity component of torch motion in they direction referenced to a fixed coordinate system

- x :

-

coordinate axis along the lateral direction

- Δx :

-

grid size

- X f :

-

distance of the closestyz face of a flaw from the origin

- Δxf :

-

dimension of the nonfusion zone in thex direction

- y :

-

coordinate axis along the direction of torch motion

- Δyf :

-

dimension of the nonfusion zone in they direction

- z:

-

coordinate axis extending downward into the workpiece from the surface

- Δzf :

-

dimension of the nonfusion zone in the z direction

- z f :

-

depth at which a flaw begins

- α :

-

thermal diffusivity in the medium and coarse zones

- ε :

-

surface emissivity value in the fine zone

- ρ :

-

density

References

M.A. Khan, N.H. Madsen, J.S. Goodling, and B.A. Chin:Optical Eng., 1986, vol. 25, pp. 799–805.

D. Rosenthal:Trans. ASME, 1946, vol. 68, pp. 849–66.

J. Goldak, M. McDill, A. Oddy. R. House, X. Chi, and M. Bibby:Advances in Welding Science and Technology, TWR ’86, Proc. Int. Conf. on Trends in Welding Research, Gatlinburg, TN, 1986, ASM INTERNATIONAL, Metals Park, OH, pp. 15–20.

K.W. Mahin, A.B. Shapiro, and J. Hallquist:Advances in Welding Science and Technology, TWR ’86, Proc. Int. Conf. on Trends in Welding Research, Gatlinburg, TN, 1986, ASM INTERNATIONAL, Metals Park, OH, pp. 215–23.

J. Goldak:Proc. Int. Conf. on Trends in Welding Technology, Gatlinburg, TN, S.A. David, ed. 1989.

J. Goldak and M. Bibby:Proc. Modeling of Casting and Welding Processes IV, A.F. Giamei and G.J. Abbaschian, eds., 1988, pp. 153-66.

P.L. Mangonon and M.A. Mahimkar:Advances in Welding Science and Technology, TWR ’86, Proc. Int. Conf. on Trends in Welding Research, Gatlinburg, TN, 1986, ASM INTERNATIONAL, Metals Park, OH, pp. 33–45.

C.C. Doumanidis, M. Hale, and D. Hardt:Advances in Welding Science and Technology, TWR ’86, Proc. Int. Conf. on Trends in Welding Research, Gatlinburg, TN, 1986, ASM INTERNATIONAL, Metals Park, OH, pp. 449–60.

G.M. Oreper and J. Szekely:J. Fluid Mech., 1984, vol. 147, pp. 53–79.

S. Kou:Welding Metallurgy, John Wiley & Sons, New York, NY, 1987, ch. 4, pp. 93–108.

T. Zacharia, S.A. David, J.M. Vitek, and T. DebRoy:Weld. J., 1989, vol. 68, pp. 499s-509s.

M.M. Chen:Interdisciplinary Issues in Materials Processing and Manufacturing, Proc. Winter Annual Meeting of ASME, Boston, MA, 1987, pp. 541-58.

Natarajan Ramanan and Seppo A. Korpela:Metall. Trans. A, 1990, vol. 21A, pp. 45–57.

W.H. Giedt:Interdisciplinary Issues in Materials Processing and Manufacturing, Proc. Winter Annual Meeting of ASME, Boston, MA, 1987, pp. 403-18.

W.E. Lukens and R.A. Morris:Weld. J., 1982, vol. 61, pp. 27–33.

S.V. Patankar:Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corp., New York, NY, 1980, ch. 4, pp. 44–47.

R.L. Ule: M.E. Thesis, Naval Postgraduate School, Monterey, CA, 1989.

M. Lu and S. Kou:Weld. J., 1988, pp. 29s-34s.

J. Goldak, M. Bibby, J. Moore, R. House, and B. Patel:Metall. Trans. B, 1986, vol. 17B, pp. 587–600.

J. Crank:Free and Moving Boundary Problems, Clarendon Press, Oxford, United Kingdom, 1987, ch. 6, pp. 217–53.

H.G. Kraus:Weld. J., 1989, vol. 68, pp. 269s-279s.

J.F. Lancaster:Metallurgy of Welding, 4th ed., Allen and Unwin, London, 1987, ch. 3, pp. 47–48.

K. Masubuchi:Analysis of Welded Structures, Pergamon Press, Oxford, United Kingdom, 1980, p. 85.

F.P. Incropera and D.P. DeWitt:Introduction to Heat Transfer, John Wiley & Sons, New York, NY, 1985, p. 672.

Author information

Authors and Affiliations

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/BF02651237.

Rights and permissions

About this article

Cite this article

Ule, R.L., Joshi, Y. & Sedy, E.B. A new technique for three-dimensional transient heat transfer computations of autogenous arc welding. Metall Trans B 21, 1033–1047 (1990). https://doi.org/10.1007/BF02670274

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02670274