Abstract

Effects of process parameters on diamond film synthesis in DC thermal plasma jet reactors are discussed including substrate material, methane concentration and substrate temperature. Diamond has been deposited on silicon, molybdenum, tungsten, tantalum, copper, nickel, titanium, and stainless steel. The adhesion of diamond film to the substrate is greatly affected by the type of substrate used. It has been found that the methane concentration strongly affects the grain size of the diamond films. Increased methane concentrations result in smaller grain sizes due to the increased number of secondary nucleations on the existing facets of diamond crystals. Substrate temperature has a strong effect on the morphology of diamond films. With increasing substrate temperature, the predominant orientation of the crystal growth planes changes from the (111) to the (100) planes. Studies of the variation of the film quality across the substrate due to the nonuniformity of thermal plasma jets indicate that microcrystalline graphite formation starts at the corners and edges of diamond crystals when the conditions become unfavorable for diamond deposition.

Similar content being viewed by others

References

R. C. DeVries,Annu. Rev. Mater. Sci. 17, 167 (1987).

R. Messier, A. R. Badzian, T. Badzian, K. E. Spear, P. Bachmann, and R. Roy,Thin Solid Films 153, 1 (1987).

R. Roy,Nature (London) 325, 17 (1987).

J. C. Angus and C. C. Hayman,Science 241, 913 (1988).

K. E. Spear,J. Am. Ceram. Soc. 72, 171 (1989).

J. C. Angus, F. A. Buck, M. Sunkara, T. F. Groth, C. C. Hayman, and R. Gat,MRS Bull. October, 38 (1989).

W. A. Yarbrough and R. Messier,Science 247, 688 (1990).

J. C. Angus, “History and Current Status of Diamond Growth at Metastable Conditions,”Proc. of tire 1st Int. Symp. on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p. 1.

N. Fujimori and A. Hara, “Technological Application of CVD Diamond,”ibid., p. 14.

C. V. Deshpandey and R. F. Bunshah,J. Vac. Sci. Technol. A7, 2294 (1989).

P. K. Bachmann and H. Lydtin, “Diamond Forming Discharges,”Mater. Res. Soc. Symp. Proc., Vol. 165, Characterization of Plasma-Enhanced CVD Processes, Materials Research Society, Pittsburgh, Pennsylvania, 1989, G. Lucovsky, D. E. Ibbotson, and D. W. Hess, eds. (1989), p. 181.

T. R. Anthony,Vacuum 41, 1356 (1990).

G. Janssen, W. J. P. van Enckevort, and L. J. Giling, “CVD Growth of Diamond: The Multiple Role of Atomic Hydrogen,”Proc. of the 1st Int. Symp. on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p. 508.

R. Pool,Science 249, 27 (1990).

S. Matsumoto, M. Hino, and T. Kobayashi,Appl. Phys. Lett. 51, 737 (1987).

K. Kurihara, K. Sasaki, M. Kawarada, and N. Koshino,Appl. Phys. Lett. 52, 437 (1988).

S. Matsumoto, “Deposition of Diamond from Thermal Plasma,”Diamond arid Diamond-Like Materials Synthesis, MRS Extended Abstracts, Materials Research Society, Pittsburgh, Pennsylvania, 1988, G. H. Johnson, A. R. Badzian, and M. W. Geis, eds. (1988), p. 119.

N. Ohtake and M. Yoshikawa,J. Electrochem. Soc. 137, 717 (1990).

P. Klocek, J. Hoggins, P. Taborek, and T. Mckenna, “CVD Diamond by DC Plasma Torch, “SPIE Proceedings, Vol. 1325, Diamond Optics III, SPIE (the Int. Suc. for Optical Eng.), A. Feldman, and S. Holly, eds. (1990), p. 63.

W. K. Kim and K. W. Whang, “Preparation of Diamond Film by DC Thermal Plasma,”Proc. of 2nd Int. Coral. on New Diamond Sci. Technol., Materials Research Society, Pittsburgh, Pennsylvania, R. Messier, J. T. Glass, J. E. Butler, and R. Roy, eds. (1991), p. 491.

M. A. Cappelli, T. G. Owano, and C. H. Kruger,J. Mater. Res. 5, 2326 (1990).

S. Matsumoto, “Development of CVD Diamond Synthesis Techniques,”Proc. of the 1st Int. Symp. on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p. 50.

P. K. Bachmann, H. Lydtin, D. U. Wiechert, J. J. Beulens, G. M. W. Kroesen, and D. C. Schram, “Diamond Deposition from a Cascaded Arc DC Plasma,”Proc. of the 3rd Int. Conf. on Surface Modification Technologies, Surface Modification Technologies III, The Mineral, Metals, and Materials Soc., Warrendale, Pennsylvania, T. S. Sudarshan and D. G. Bhat, eds. (1990), p. 69.

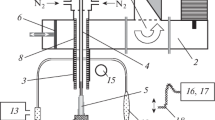

Z. P. Lu, L. Stachowicz, P. Kong, J. Heberlein, and E. Pfender,Plasma Chem. Plasma Process. 11, 387 (1991).

X-Ray Powder Diffraction Data for Diamond, Card No. 6-675, Am. Soc. Testing Mater.

O. Matsumoto, R. Furukawa, and H. Uyama, “Diamond Deposition on Some Transition Metal Substrates with Plasma Jet under Reduced Pressure,”Proc. of the 9th Int. Symp. on Plasma Chem., Vol. 2, Pugnochiuso, Italy, 1989, R. d'Agostino, ed. (1989), p. 1427.

C. F. Chen, E. Ko, S. Hosomi, and I. Yoshida,Hyomen Gijutsu (Surface Technology, in Japanese) 41, 665 (1990).

S. Soderberg, A. Gerendas, and M. Sjostrand,Vacuum 41, 1317 (1990).

K. Saijo, M. Yagi, K. Shibuki, and S. Takatsu,Surf. Coatings Tech. 43/44, 30 (1990).

K. Kobashi, K. Nishimura, Y. Kawate, and T. Horiuchi,Phys. Rev. B: Condens. Matter 38, 4067 (1988).

K. E. Spear and M. Frenklach, “Mechanisms of Nucleation and Growth of CVD Diamond,”Proc. of the 1st Int. Symp., on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p. 122.

W. Zhu, R. Messier, and A. R. Badzian, “Effects of Process Parameters on CVD Diamond Films,”ibid., p. 61.

H. Murayama and T. Maeda,Nature (London) 345, 791 (1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lu, Z.P., Heberlein, J. & Pfender, E. Process study of thermal plasma chemical vapor deposition of diamond, part I: Substrate material, temperature, and methane concentration. Plasma Chem Plasma Process 12, 35–53 (1992). https://doi.org/10.1007/BF01447943

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01447943