Abstract

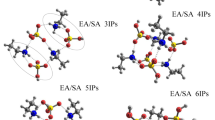

This paper reports-the results of the first-principles molecular dynamics calculations of the NaF–AlF3 electrolyte molten salt system with a low molecular ratio (1.3). The local ion structures of the NaF–AlF3 molten salt system mainly included four-coordination [AlF4]–, five-coordination [AlF5]2–, and a few six-coordination [AlF6]3– structures. The first peak of the radial distribution function of the Al–F ion pair was the highest, and the interactions between Al and F ions were strong, which made the molten salt structure complex. The average coordination number of the Al–F ion pair was 4.53. The coordination distribution of the ion structure was that four-coordination [AlF4]– and five-coordination [AlF5]2– structures accounted for more than 90%, while six-coordination [AlF6]3– structures accounted for less than 10%. The F ion type distribution was mainly terminal fluorine Ft, while bridge fluorine Fb and free fluorine Ff accounted for less.The angular distribution of the Al–F–Al bond was 94°, 114°, and 171°. The Al–F bond has ionic properties, but because F-2p is hybridized with Al-3s and 3p orbitals, Al–F ions also have covalent properties. The average Mulliken bond population of Al–F was 0.29, which is much larger than that of F–F and Na–F. Therefore, the covalent interactions between Al–F ion pairs were strong. The order of ion diffusion ability in the NaF–AlF3 molten salt was Na+ > F– > Al3+. The viscosity of the molten salt was 1.479 mPa s, and the ionic conductivity was 1.306 S/cm. These calculation results provide data support for the application of the NaF–AlF3 low-temperature aluminum electrolyte system.

Similar content being viewed by others

REFERENCES

R. Mukhlis, M. A. Rhamdhani, and G. Brooks, TMS Light Met. 2010, 883 (2010).

Z. G. Li, China Nonferr. Met., No. 5 (2), 38 (2022).

Y. X. Liu and J. Li, Modern Aluminum Electrolysis (Metallurgical Industry Press, 2008), p. 3.

B. Gilbert, G. Mamantov, and G. M. Begun, Inorg. Nucl. Chem. Lett. 10, 1123 (1974). https://doi.org/10.1016/0020-1650(74)80177-7

B. Gilbert and T. Materne, Appl. Spectrosc. 44, 299 (1990). https://doi.org/10.1366/0003702904085525

B. Gilbert, E. Robert, E. Tixhon, et al., Inorg. Chem. 35, 4198 (1996). https://doi.org/10.1021/ic951660l

E. Tixhon, E. Robert, and B. Gilbert, Appl. Spectrosc. 48, 1477 (1994). https://doi.org/10.1366/0003702944027769

C. Malherbe and B. Gilbert, Anal. Chem. 85 (18), 8669 (2013). https://doi.org/10.1021/ac401490j

V. Lacassagne, C. Bessada, P. Florian, et al., J. Phys. Chem. B 106, 1862 (2002). https://doi.org/10.1021/jp013114l

I. Nuta, E. Veron, G. Matzen, et al., Inorg. Chem. 50, 3304 (2011). https://doi.org/10.1021/ic1019845

J. F. Stebbins, I. Farnan, N. Dando, et al., J. Am. Ceram. Soc. 75, 3001 (1992). https://doi.org/10.1111/j.1151-2916.1992.tb04378.x

S. V. Abramov, N. S. Chilingarov, A. Y. Borshchevsky, et al., Int. J. Mass Spectrom. 231, 31 (2004). https://doi.org/10.1016/j.ijms.2003.09.006

S. Cikit, Z. Akdeniz, and P. A. Madden, J. Phys. Chem. B 118, 1064 (2014). https://doi.org/10.1021/jp4080459

X. J. Lv, Z. M. Xu, J.Li, J. G. Chen, and Q. S. Liu, J. Fluorine Chem. 185, 42 (2016). https://doi.org/10.1016/j.jfluchem.2016.03.004

X. J. Lv, Z. M. Xu, J. Li, et al., J. Mol. Liq. 221, 26 (2016). https://doi.org/10.1016/j.molliq.2016.05.064

X. W. Liu, J. L. You, Y. Y. Wang, et al., J. Light Scatter. 26 (4), 6 (2014). https://doi.org/10.13883/j.issn1004-5929.201403009

X. W. Liu, J. L. You, Y. Y. Wang, et al., Chin. J. Nonferr. Met. 24, 286 (2014).

T. Zhao, J. L. You, Y. Y. Wang, et al., J. Light Scatter. 24, 7 (2012). https://doi.org/10.3969/j.issn.1004-5929.2012.01.001

L. Cassayre, P. Palau, P. Chamelot, et al., J. Chem. Eng. Data 55, 4549 (2010). https://doi.org/10.1021/je100214x

C. H. Zhou, S. L. Ma, and J. Y. Shen, Nonferr. Met. 50, 81 (1998).

Z. Rong, J. Ding, W. Wang, et al., Sol. Energy Mater. Sol. Cells 216, 110696 (2020). https://doi.org/10.1016/j.solmat.2020.110696

H. Guo, J. Li, H. Zhang, et al., Chem. Phys. Lett. 730, 587 (2019). https://doi.org/10.1016/j.cplett.2019.06.060

A. Bengtson, H. O. Nam, S. Saha, et al., Comput. Mater. Sci. 83, 362 (2014). https://doi.org/10.1016/j.commatsci.2013.10.043

R. Vuilleumier, A. Seitsonen, N. Sator, et al., Geochim. Cosmochim. Acta 141, 547 (2014). https://doi.org/10.1016/j.gca.2014.06.037

X. J. Lv, Z. Xun, et al., Phys. Chem. Chem. Phys. 21, 7474 (2019). https://doi.org/10.1039/c9cp00377k

W. Brockner, K. Tørklep, and H. A. Øye, Ber. Bunsenges. Phys. Chem. 83, 12 (2010). https://doi.org/10.1002/bbpc.19790830103

J. Híve and J. Thonstad, Electrochim. Acta 49, 5111 (2004). https://doi.org/10.1016/j.electacta.2004.06.022

ACKNOWLEDGMENTS

Financial supported by NSFC 52064030, Yunnan Major Scientific and Technological Projects (grant nos. 202202AG050007, 202202AG050017), and Yunnan Industrial Talent project YNQR-CYRC-2018-003 are acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Zhang, L., Chen, X., Yan, H. et al. First-Principles Molecular Dynamics Study of a NaF–AlF3 Molten Salt with a Low Molecular Ratio. Russ. J. Phys. Chem. 97, 1558–1566 (2023). https://doi.org/10.1134/S0036024423070142

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024423070142