Abstract

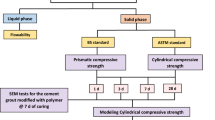

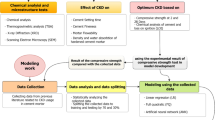

Using two different test standards (ASTM and BS), the influence of five different sizes of sand on the ultimate stress (MPa) of hand-mixed cement-grouted sands modified with polymer is discussed in this study. The characteristics of cement-grouted sands modified with polymer up to 0.16% (percent weight of dry cement) were evaluated and measured in fresh and hardened conditions. Adding polymer decreased the water/cement ratio (\(w/c\)) from 0.6 to 0.5, and it kept the flow time of the cement-based grout in the range of 18 to 23 s recommended by ASTM standard. Using mix proportion and curing time, adding polymer significantly increased the prismatic and cylindrical compressive strength (MPa) by 113 to 577% and 53 to 459%. Several mathematical approaches such as linear regression (LR), Nonlinear regression (NLR), multilinear regression (MLR), Artificial neural network (ANN), and M5P-tree were used to predict the compression strength of cement-grouted sand with a different size of sand, w/c, polymer content, and curing age. Based on the scatter index (SI), objective function (OBJ) assessments, and training and testing datasets, the compressive strength of the cement-grouted sands can be predicted well using NLR and ANN models. The compression strength tested using the BS standard was 71% higher than the compression strength of the same mix tested using the ASTM standard.

Similar content being viewed by others

Data availability

No data, models, or code were generated or used during the study.

References

Ozgurel HG, Vipulanandan C. Effect of grain size and distribution on permeability and mechanical behavior of acrylamide grouted sand. J Geotech Geoenviron Eng. 2005;131(12):1457–65.

Hicher PY, Dano C, Chang C. Multi-scale modelling of the mechanical behaviour of grouted sand. Studia Geotechnica et Mechanica. 2008:1.

Beushausen H, Luco LF. Performance-based specifications and control of concrete durability. RILEM TC. State-of-the-Art Report RILEM TC 230-PSC; 2016. pp. 66–72. https://doi.org/10.1007/978-94-017-7309-6.

Celik F, Canakci H. An investigation of rheological properties of cement-based grout mixed with rice husk ash (RHA). Constr Build Mater. 2015;91:187–94.

Stille H, Gustafson G, Hassler L. Application of new theories and technology for grouting of dams and foundations on rock. Geotech Geol Eng. 2012;30(3):603–24.

Mahmood W, Mohammed A, Ghafor K. Viscosity, yield stress and compressive strength of cement-based grout modified with polymers. Results Materials. 2019;4: 100043. https://doi.org/10.1016/j.rinma.2019.100043.

Mohammed A, Mahmood W, Ghafor K. TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr Build Mater. 2020a;235:117534.

Mohammed A, Mahmood W, Ghafor K. Shear stress limit, rheological properties and compressive strength of cement-based grout modified with polymers. J Build Pathol Rehabil. 2020;5(1):3. https://doi.org/10.1007/s41024-019-0069-1.

Hussin MW, Kang LS, Zakaria F. Engineering properties of high volume slag cement grout in tropical climate. Malaysian J Civil Eng. 2007;19(1):42–54.

Güllü H. On the viscous behavior of cement mixtures with clay, sand, lime and bottom ash for jet grouting. Constr Build Mater. 2015;93:891–910.

Benyounes K. Rheological behavior of cement-based grout with Algerian bentonite. SN Appl Sci. 2019;1(9):1–8.

Salih A, Rafiq S, Mahmood W, Hind AD, Noaman R, Ghafor K, Qadir W. Systemic multiscale approaches to predict the flowability at various temperature and mechanical properties of cement paste modified with nano-calcium carbonate. Constr Build Mater. 2020;262:120777.

Nonveiller E. Grouting theory and practice. Elsevier; 2013.

Bart F, Cau-di-Coumes C, Frizon F, Lorente S, editors. Cement-based materials for nuclear waste storage. Springer Science & Business Media; 2012.

Dehghan SM, Najafgholipour MA, Baneshi V, Rowshanzamir M. Experimental study on effect of water-cement ratio and sand grading on workability and mechanical properties of masonry mortars in Iran. Iranian J Sci Technol Trans Civil Eng. 2019;43(1):21–32.

Mohammed A, Burhan L, Ghafor K, Sarwar W, Mahmood W. Artificial neural network (ANN), M5P-tree, and regression analyses to predict the early age compression strength of concrete modified with DBC-21 and VK-98 polymers. Neural Comput Appl. 2020;33:7851–73.

Zhilkina T, Sychugov S, Gumeniuk A, Mackevicius R, Turchin V, Vasilev V, Ilinsky A. Technology of soil stabilization with cement-sand grouting mortar with optimal aggregate grading. In MATEC Web of Conferences; 2018 (Vol. 193, p. 05046). EDP Sciences.

Falade F. Influence of water/cement ratios and mix proportions on workability and characteristic strength of concrete containing laterite fine aggregate. Build Environ. 1994;29(2):237–40.

Westerholm M, Lagerblad B, Silfwerbrand J, Forssberg E. Influence of fine aggregate characteristics on the rheological properties of mortars. Cement Concr Compos. 2008;30(4):274–82.

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W. Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J Build Eng. 2020. https://doi.org/10.1016/j.jobe.2020.101851.

Mohammed A, Rafiq S, Mahmood W, Al-Darkazalir H, Noaman R, Qadir W, Ghafor K. Artificial Neural Network and NLR techniques to predict the rheological properties and compression strength of cement past modified with nanoclay. Ain Shams Eng J. 2020;12(2):1313–28.

Mohammed A, Rafiq S, Mahmood W, Noaman R, Hind AD, Ghafor K, Qadir W. Microstructure characterizations, thermal properties, yield stress, plastic viscosity and compression strength of cement paste modified with nanosilica. J Market Res. 2020;9(5):10941–56.

Mohammed A, Rafiq S, Mahmood W, Noaman R, Ghafor K, Qadir W, Kadhum Q. Characterization and modeling the flow behavior and compression strength of the cement paste modified with silica nano-size at different temperature conditions. Constr Build Mater. 2020;257:119590.

Ding W, Nguyen MD, Mohammed AS, Armaghani DJ, Hasanipanah M, Van Bui L, Pham BT. A new development of ANFIS-Based Henry gas solubility optimization technique for prediction of soil shear strength. Transportation Geotech. 2021;29:100579.

Yu C, Koopialipoor M, Murlidhar BR, Mohammed AS, Armaghani DJ, Mohamad ET, Wang Z. Optimal ELM–Harris Hawks optimization and ELM–Grasshopper optimization models to forecast peak particle velocity resulting from mine blasting. Nat Resour Res. 2021;30(3):2647–62.

Sarwar W, Ghafor K, Mohammed A. Modeling the rheological properties with shear stress limit and compressive strength of ordinary Portland cement modified with polymers. J Build Pathol Rehabil. 2019;4(1):25.

Cai M, Hocine O, Mohammed AS, Chen X, Amar MN, Hasanipanah M. Integrating the LSSVM and RBFNN models with three optimization algorithms to predict the soil liquefaction potential. Eng Comput. 2021. https://doi.org/10.1007/s00366-021-01392-w.

Qadir W, Ghafor K, Mohammed A. Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civil Eng. 2019;2019:1–11.

Burhan L, Ghafor K, Mohammed A. Evaluation and nonlinear quantification of early age strength of concrete containing PCE polymer. MS&E. 2020;737(1):012061.

Sarwar W, Ghafor K, Mohammed A. Regression analysis and Vipulanandan model to quantify the effect of polymers on the plastic and hardened properties with the tensile bonding strength of the cement mortar. Results Mater. 2019;1:100011.

Sihag P, Jain P, Kumar M. Modelling of impact of water quality on recharging rate of storm water filter system using various kernel function based regression. Modeling Earth Syst Environ. 2018;4(1):61–8.

Dundu M, Gao X, editors. Construction materials and structures: Proceedings of the First International Conference on Construction Materials and Structures. IOS Press; 2014.

Fernández JM, Duran A, Navarro-Blasco I, Lanas J, Sirera R, Alvarez JI. Influence of nanosilica and a polycarboxylate ether superplasticizer on the performance of lime mortars. Cem Concr Res. 2013;43:12–24.

Elmakki R, Masalova I, Haldenwang R, Malkin A, Mbasha W. Effect of limestone on the cement paste hydration in the presence of polycarboxylate superplasticiser. Appl Rheol. 2016;26(2):20–7.

Khudhair MH, Elharfi A, El-Youbi MS. The effect of polymeric admixtures of water reduce of superplasticizer and setting accelerator on physical properties and mechanical performance of mortars and concretes. J Environ Res. 2018;1(1):4.

Mohammed A, Salih A, Raof H. Vipulanandan constitutive models to predict the rheological properties and stress–strain behavior of cement grouts modified with metakaolin. J Test Eval. 2020;48(5):20180271.

Mahmood W, Mohammed A. Hydraulic conductivity, grain size distribution (GSD) and cement injectability limits predicted of sandy soils using vipulanandan models. Geotech Geol Eng. 2019. https://doi.org/10.1007/s10706-019-01153-z.

Mahmood W, Mohammed A. New Vipulanandan pq model for particle size distribution and groutability limits for sandy soils. J Test Eval. 2020;48(5):20180606.

Vipulanandan C, Mohammed A. Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval. 2019;47(2):1479–501.

Vipulanandan C, Mohammed A. Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct. 2015;24(12):125020.

Mohammed AS. Vipulanandan models to predict the electrical resistivity, rheological properties and compressive stress-strain behavior of oil well cement modified with silica nanoparticles. Egypt J Pet. 2018;27(4):1265–73.

Mohammed A, Vipulanandan C. Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. Geotech Geol Eng. 2015;33(4):1099–114.

Mohammed A, Mahmood W. Vipulanandan failure models to predict the tensile strength, compressive modulus, fracture toughness, and ultimate shear strength of calcium rocks. Int J Geotech Eng. 2018;15(2):129–39.

Li Y, Oh J, Mitra R, Hebblewhite B. Experimental studies on the mechanical behaviour of rock joints with various openings. Rock Mech Rock Eng. 2016;49(3):837–53.

Lim SK, Ling TC, Hussin MW. Strength properties of self-compacting mortar mixed with GGBFS. Proc Inst Civil Eng-Constr Mater. 2012;165(2):87–98.

Neville AM. Properties of concrete, vol. 4. London: Longman; 1995.

Quinlan JR. Learning with continuous classes. In 5th Australian joint conference on artificial intelligence (Vol. 92, pp. 343–348); 1992.

Hamad AJ. Size and shape effect of specimen on the compressive strength of HPLWFC reinforced with glass fibres. J King Saud Univ-Eng Sci. 2017;29(4):373–80.

Dehestani M, Nikbin IM, Asadollahi S. Effects of specimen shape and size on the compressive strength of self-consolidating concrete (SCC). Constr Build Mater. 2014;66:685–91.

Funding

No fund was received for this study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmood, W., Mohammed, A.S., Sihag, P. et al. Interpreting the experimental results of compressive strength of hand-mixed cement-grouted sands using various mathematical approaches. Archiv.Civ.Mech.Eng 22, 19 (2022). https://doi.org/10.1007/s43452-021-00341-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00341-0