Abstract

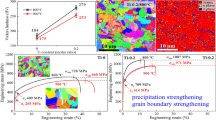

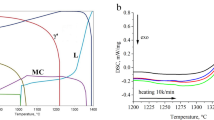

In this work, the solidification behavior and hot tearing susceptibility (HTS) of Mg–4Y–xNi (x = 0.5, 1, 2, 3, 4 wt%) alloys were investigated through the thermal analysis (TA) method and a constrained rod casting system. The solidification characteristics parameters measured by TA method were coupled with the prevailing hot tearing criteria for predicting HTS of the alloys, and then compared with the experimental results. Subsequently, the hot tearing mechanism was studied upon shrinkage stress development, solidification characteristics and microstructure evolutions. The results showed that Kou’s criterion accurately and effectively predicted HTS of the alloys, that is, HTS of the alloys exhibited a Λ-shaped trend with increasing Ni content, peaking at a Ni content of 1 wt%. HTS of the alloys depended primarily on the dendrite coherency, residual liquid and LPSO-bridging. The delay in dendrite coherency prolonged the free feeding interval, which in conjunction with the increased residual liquid fraction improved the feeding capacity of the alloys at the end of solidification and decreased HTS. The higher degree of bridging between adjacent grains of alloys with higher solid fraction at dendrite coherency implies a higher skeleton strength of the alloys. In particular, when the LPSO phase precipitates at grain boundaries to form grain boundary bridges, it effectively hinders the initiation and propagation of hot tearing. This is due to its certain orientation relationship with the α-Mg matrix, which will significantly increase the grain boundary strength by strongly pinning the grains on both sides.

Similar content being viewed by others

References

J.B. Lyu, J.Y. Kim, H.X. Liao, J. She, J.F. Song, J. Peng, F.S. Pan, B. Jiang, Effect of substitution of Zn with Ni on microstructure evolution and mechanical properties of LPSO dominant Mg–Y–Zn alloys. Mater. Sci. Eng. A 773, 138735 (2020). https://doi.org/10.1016/j.msea.2019.138735

Y. Kawamura, M. Yamasaki, Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure. Mater. Trans. 47, 2986–2992 (2007). https://doi.org/10.2320/matertrans.MER2007142

H. Liu, H. Huang, J.P. Sun, C. Wang, J. Bai, A.B. Ma, X.H. Chen, Microstructure and mechanical properties of Mg-RE-TM cast alloys containing long period stacking ordered phases: a review. Acta Metall. Sin.-Engl. Lett. 32, 269–285 (2019). https://doi.org/10.1007/s40195-018-0862-x

S.R. Zhang, J.Y. Kim, F.X. Wang, K.K. Kang, H. Xue, X.H. Chen, F.S. Pan, Microstructure and mechanical properties of LPSO dominant Mg–2Y–Cu–TM (TM=Cu, Zn Co, Ni) alloys. Mater Charact 191, 112111 (2022). https://doi.org/10.1016/j.matchar.2022.112111

F.S. Pan, M.B. Yang, X.H. Chen, A review on casting magnesium alloys: modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 32, 1211–1221 (2016). https://doi.org/10.1016/j.jmst.2016.07.001

P. Gunde, A. Schiffl, P.J. Uggowitzer, Influence of yttrium additions on the hot tearing susceptibility of magnesium-zince alloys. Mater. Sci. Eng. A 527, 7074–7079 (2010). https://doi.org/10.1016/j.msea.2010.07.086

H. Qin, G.Y. Yang, X.W. Zheng, S.F. Luo, T. Bai, W.Q. Jie, Effect of Gd content on hot-tearing susceptibility of Mg–6Zn–xGd casting alloys. China Foundry 19, 131–139 (2022). https://doi.org/10.1007/s41230-022-1117-z

Y. Li, H. Li, L. Katgerman, Q. Du, J. Zhang, L. Zhuang, Recent advances in hot tearing during casting of aluminium alloys. Prog. Mater. Sci. 117, 100741 (2021). https://doi.org/10.1016/j.pmatsci.2020.100741

J.W. Liu, S. Kou, Susceptibility of ternary aluminum alloys to cracking during solidification. Acta Mater. 125, 513–523 (2017). https://doi.org/10.1016/j.actamat.2016.12.028

I. Farup, A. Mo, Two-phase modeling of mushy zone parameters associated with hot tearing. Metall. Metal. Trans. A 31, 1461–1472 (2000). https://doi.org/10.1007/s11661-000-0264-2

G. Cao, C. Zhang, H. Cao, Y.A. Chang, S. Kou, Hot-tearing susceptibility of ternary Mg–Al–Sr alloy castings. Metall. Metal. Trans. A 41, 706–716 (2010). https://doi.org/10.1007/s11661-009-0134-5

Z. Liu, S.B. Zhang, P.L. Mao, F. Wang, Effects of Y on hot tearing formation mechanism of Mg–Zn–Y–Zr alloys. Mater. Sci. Technol. 30, 1214–1222 (2014). https://doi.org/10.1179/1743284713Y.0000000437

S.M. Li, K. Sadayappan, D. Apelian, Role of grain refinement in the hot tearing of cast Al–Cu alloy. Metall. Metal. Trans. A 44, 614–623 (2013). https://doi.org/10.1007/s11663-013-9801-4

G.N. Zhu, Z. Wang, W.Y. Qin, Y. Zhou, L. Zhou, F. Wang, Z. Liu, P.L. Mao, Effect of Yttrium on hot tearing susceptibility of Mg–6Zn–1Cu–0.6Zr alloys. Int. Metalcast. 14, 179–190 (2020). https://doi.org/10.1007/s40962-019-00352-x

Z.Q. Wei, W.P. Mu, S.M. Liu, F. Wang, L. Zhou, Z. Wang, P.L. Mao, Z. Liu, Effects of Gd on hot tearing susceptibility of as-cast Mg96.94–Zn1–Y(2–x)–Gdx–Zr0.06 alloys reinforced with LPSO phase. J. Alloys Compd. 926, 166895 (2022). https://doi.org/10.1016/j.jallcom.2022.166895

G.J. Zhang, Y. Wang, Z. Liu, S.M. Liu, Influence of Al addition on solidification path and hot tearing susceptibility of Mg-2Zn-(3+0.5x)Y-xAl alloys. J. Magnes. Alloy. 7, 272–282 (2019). https://doi.org/10.1016/j.jma.2019.04.001

S.M. Liu, Z.Q. Wei, Z. Liu, P.L. Mao, F. Wang, Z. Wang, L. Zhou, X.N. Yin, Effect of Zn content on hot tearing susceptibility of LPSO enhanced Mg-Znx-Y2-Zr0.06 alloys with different initial mold temperatures. J. Alloys Compd. 904, 163963 (2022). https://doi.org/10.1016/j.jallcom.2022.163963

X. Yang, S.S. Wu, S.L. Lu, L.Y. Hao, X.G. Fang, Effects of Ni levels on microstructure and mechanical properties of Mg–Ni–Y alloy reinforced with LPSO structure. J. Alloys Compd. 726, 276–283 (2017). https://doi.org/10.1016/j.jallcom.2017.08.003

Z.Q. Wei, S.M. Liu, Z. Liu, L. Zhou, Y. Li, P.L. Mao, F. Wang, Z. Wang, Effects of Zn content on hot tearing susceptibility of Mg–Zn–Gd–Y–Zr alloys. Int. Metalcast. 16, 1902–1914 (2022). https://doi.org/10.1007/s40962-021-00720-6

F. Shi, C.Q. Wang, Z.M. Zhang, Microstructures, corrosion and mechanical properties of as-cast Mg–Zn–Y–(Gd) alloys. Trans. Nonferrous Met. Soc. China 25, 2172–2180 (2015). https://doi.org/10.1016/S1003-6326(15)63829-8

H. Liu, F. Xue, J. Bai, J. Zhou, X.D. Liu, Effect of substitution of 1 at% Ni for Zn on the microstructure and mechanical properties of Mg94Y4Zn2 alloy. Mater. Sci. Eng. A 585, 387–395 (2013). https://doi.org/10.1016/j.msea.2013.07.036

S.M. Zhu, R. Lapovok, J.F. Nie, Y. Estrin, S.N. Mathaudhu, Microstructure and mechanical properties of LPSO phase dominant Mg85.8Y7.1Zn7.1 and Mg85.8Y7.1Ni7.1 alloys. Mater. Sci. Eng. A 692, 35–42 (2017). https://doi.org/10.1016/j.msea.2017.03.057

H.N. Yu, S.M. Liu, L. Zhou, Z. Liu, Z.Q. Wei, H. Guo, Study on solidification behavior and hot tearing susceptibility of Mg-2xY-xNi alloys. Int. J. Metalcast. 15, 995–1005 (2021). https://doi.org/10.1007/s40962-020-00531-1

Z.S. Zhen, N. Hort, Y.D. Huang, N. Petri, O. Utke, K.U. Kainer, Quantitative determination on hot tearing in Mg–Al binary alloys. Mater. Sci. Forum 618–619, 533–540 (2009). https://doi.org/10.4028/www.scientific.net/MSF.618-619.533

S. Farahany, H.R. Bakhsheshi-Rad, M.H. Idris, M.R.A. Kadir, A.F. Lotfabadi, A. Ourdjini, In-situ thermal analysis and macroscopical characterization of Mg-xCa and Mg-0.5Ca-xZn alloy systems. Thermochim. Acta 527, 180–189 (2012). https://doi.org/10.1016/j.tca.2011.10.027

S. Mostafapoor, M. Malekan, M. Emamy, Effects of Zr addition on solidification characteristics of Al–Zn–Mg–Cu alloy using thermal analysis. J. Therm. Anal. Calorim. 134, 1457–1469 (2018). https://doi.org/10.1007/s10973-018-7426-1

D.G. Eskin, L. Katgerman, A quest for a new hot tearing criterion. Metall. Mater. Trans. A 38, 1511–1519 (2007). https://doi.org/10.1007/s11661-007-9169-7

T.W. Clyne, G.J. Davies, The influence of composition on solidification cracking susceptibility in binary alloys. Br. Foundrym. 741, 65–73 (1981)

S. Kou, A criterion for cracking during solidification. Acta Mater. 88, 366–374 (2015). https://doi.org/10.1016/j.actamat.2015.01.034

B. Hu, D.J. Li, Z.X. Li, J.K. Xu, X.Y. Wang, X.Q. Zeng, Hot tearing behavior in double ternary eutectic alloy system: Al–Mg–Si alloys. Metall. Metal. Trans. A 52, 789–805 (2021). https://doi.org/10.1007/s11661-020-06101-8

K. Liu, S. Kou, Susceptibility of magnesium alloys to solidification cracking. Sci. Technol. Weld. Join. 25, 251–257 (2019). https://doi.org/10.1080/13621718.2019.1681160

X.D. Du, F. Wang, Z. Wang, L. Zhou, Z.Q. Wei, Z. Liu, P.L. Mao, Effect of Ca/Al ratio on hot tearing susceptibility of Mg–Al–Ca alloy. J. Alloys Compd. 911, 165113 (2022). https://doi.org/10.1016/j.jallcom.2022.165113

C.Y. Yue, X.G. Yuan, Y.X. Wang, M. Su, Effect of adding Pr on the microstructure and hot tearing sensitivity of as-cast Al–Cu–Mg alloys. Mater Charact 191, 112141 (2022). https://doi.org/10.1016/j.matchar.2022.112141

B.C. Li, J. Zhang, F.W. Ye, R.Y. Tang, Q. Dong, J.H. Chen, An approach to studying the hot tearing mechanism of alloying elements in ternary Mg–Zn–Al alloys. J. Mater. Process. Tech. 317, 117980 (2023). https://doi.org/10.1016/j.jmatprotec.2023.117980

C. Muthuraja, I. Balasundar, K.R. Ravi, Determination of liquid fraction in Mg–Zn–Y alloys: thermal analysis versus thermodynamic approach. Trans. Indian Inst. Met. 71, 2807–2811 (2018). https://doi.org/10.1007/s12666-018-1419-4

X.H. Shao, Z.Q. Yang, X.L. Ma, Strengthening and toughening mechanisms in Mg–Zn–Y alloy with a long period stacking ordered structure. Acta Mater. 58, 4760–4771 (2010). https://doi.org/10.1016/j.actamat.2010.05.012

W.J. Ci, L.L. Deng, X.H. Chen, X. Dai, L. Feng, C. Wen, J.Y. Bai, F.S. Pan, Effect of minor Gd addition on microstructure, mechanical performance, and corrosion behavior of Mg–Y–Gd alloys. J. Mater. Res. Technol. JMRT 26, 4107–4120 (2023). https://doi.org/10.1016/j.jmrt.2023.08.166

Z.L. Wang, Q. Luo, S.L. Chen, K.C. Chou, Q. Li, Experimental investigation and thermodynamic calculation of the Mg–Ni–Y system (Y<50 at.%) at 400 and 500 °C. J. Alloys Compd. 649, 1306–1314 (2015)

X. Yang, S.S. Wu, S.L. Lu, L.Y. Hao, X.G. Fang, Refinement of LPSO structure in Mg–Ni–Y alloys by ultrasonic treatment. Ultrason. Sonochem. 40, 472–479 (2018). https://doi.org/10.1016/j.ultsonch.2017.07.042

X.H. Shao, Z.Q. Yang, J.H. You, K.Q. Qiu, X.L. Ma, Microstructure and microhardness evolution of a Mg83Ni6Zn5Y6 alloy upon annealing. J. Alloys Compd. 509, 7221–7228 (2011). https://doi.org/10.1016/j.jallcom.2011.04.067

Acknowledgements

This work is financially supported by the Liaoning Nature Fund Guidance Plan (No. 2022-BS-179), Project of Liaoning Education Department (Nos. LJKMZ20220467 and LJKMZ20220462) and the Key Laboratory of Magnesium alloys and Fabrication Technology of Liaoning Province.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mu, W., Wei, Z., Mao, P. et al. Effects of Ni Content on Solidification Behavior and Hot Tearing Susceptibility of LPSO-Reinforced Mg–4Y–xNi alloys. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01200-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01200-9