Abstract

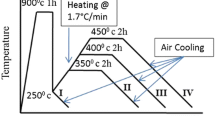

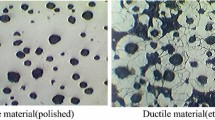

In this study, the effect of the austempering times on the microstructures and mechanical properties of dual-matrix structure austempered ductile iron (DMS-ADI) was investigated. With this aim, unalloyed as-cast ductile iron tensile samples were austenitized at 810 °C for 30 min to intercritical austenitizing followed by austempering at 350°C for various austempering times (45 min to 180 min). Experimental results showed that dual-matrix structures consisting of proeutectoid ferrite + ausferrite were obtained in austempered ductile iron from intercritical austenitizing temperatures. It was determined that as the austempering time increased, the ausferritic structure became considerably clear and its volume fraction was almost constant (45–47%) after 90 min of austempering time. The yield and tensile strength of the samples decreased and the total elongation and breaking energy increased with increasing austempering times, but after the 120-min austempering time, both the total elongation and breaking energy of the samples decreased. It was established that the austempering times had no significant effect on the morphology of ausferrite. The best mechanical properties were obtained between 70- and 130-minute austempering times that can be defined as the processing window. In addition, it was determined that the DMS-ADI had similar austempering kinetics with the ADI.

Graphic abstract

Similar content being viewed by others

Availability of Data and Material

The raw data cannot be shared at this time as the data are also part of an ongoing study.

References

V. Kilicli, M. Erdogan, Mater. Sci. Technol. 22, 919 (2006)

V. Kilicli, M. Erdogan, Int. J. Cast Metals Res. 20, 202 (2007)

V. Kilicli, M. Erdogan, J. Mater. Eng. Perform. 17, 240 (2008)

V. Kilicli, M. Erdogan, J. Mater. Eng. Perform. 19, 142 (2010)

M. Erdogan, V. Kilicli, B. Demir, Int. J. Mater. Res. 99, 751 (2008)

M. Erdogan, V. Kilicli, B. Demir, J. Mater. Sci. 44, 1394 (2009)

I. Ovali, V. Kilicli, M. Erdogan, ISIJ Int. 53, 375 (2013)

I. Ovali, A. Mavi, Int. J. Mater. Res. 104, 192 (2013)

A. Basso, J. Sikora, Int. J. Metalcast. 6, 7–14 (2012). https://doi.org/10.1007/BF03355473.

A. Basso, M. Caldera, M. Chapetti, J. Sikora, ISIJ Int. 50, 302 (2010)

A. Basso, M. Caldera, J. Massone, ISIJ Int. 55, 1106 (2015)

A. Basso, M. Caldera, G. Rivera, J. Sikora, ISIJ Int. 52, 1130 (2012)

A. Basso, R. Martinez, J. Sikora, Mater. Sci. Technol. 25, 1271 (2009)

A.D. Basso, A.L.D. Pra, M.D. Echeverria, A.D. Sosa, Int. J. Cast. Metals Res. 31, 144 (2017)

A.D. Basso, A.L.D. Pra, M.D. Echeverria, A.D. Sosa, Int. J. Cast. Metals Res. 31, 144 (2018)

D.A. Colombo, R.C. Dommarco, A.D. Basso, Wear 418, 208 (2019)

Y. Sahin, M. Erdogan, V. Kilicli, Mater. Sci. Eng. A 444, 31 (2007)

Y. Sahin, V. Kilicli, M. Ozer, M. Erdogan, Wear 268, 153 (2010)

A. Rashidi, M. Moshrefi-Torbati, Int. J. Cast. Metals Res. 13, 293 (2001)

A.M. Rashidi, M. Moshrefi-Torbati, Mater. Lett. 45, 203 (2000)

M. Soliman, H. Palkowski, A. Nofal, Int. J. Metalcast. 14, 853–860 (2020). https://doi.org/10.1007/s40962-020-00477-4

M. Soliman, H. Palkowski, A. Nofal, Arch. Metal. Mater. 62, 1493–1498 (2017)

R. Aristizabal, R. Foley, A. Druschitz, Int. J. Metalcast. 6, 7–14 (2012). https://doi.org/10.1007/BF03355534

S. Panneerselvam, S.K. Putatunda, R. Gundlach, J. Boileau, Mater. Sci. Eng. A 694, 72 (2017)

W.L. Guesser, C.L. Lopes, P.A.N. Bernardini, Int. J. Metalcast. 14, 717–727 (2020). https://doi.org/10.1007/s40962-019-00397-y

H.D. Machado, R. Aristizabal-Sierra, C. Garcia-Mateo, I. Toda-Caraballo, Int. J. Metalcast. 14, 836–845 (2020). https://doi.org/10.1007/s40962-020-00450-1

N.E. Tenaglia, D.I. Pedro, R.E. Boeri, A.D. Basso, Int. J. Cast. Metals Res. 33, 72 (2020)

F. Zanardi, C. Mapelli, S. Barella, Int. J. Metalcast. 14, 622–655 (2020). https://doi.org/10.1007/s40962-020-00454-x

A. Druschitz, M. Ostrander, R. Aristizabal, In 71st World Foundry Congress (Bilbao, Spain, 2014).

A. Druschitz, R. Aristizabal, E. Druschitz, C. Hubbard, T. Watkins, SAE Int. J. Mater. Manuf. 4, 111 (2011)

A. Druschitz, M. Ostrander, R. Aristizabal, SAE Technical Paper 01-0950, (2013).

A. Druschitz, R.E. Aristizabal, E. Druschitz, C.R. Hubbard, T.R. Watkins, L. Walker, M. Ostrander, Metall. Mater. Trans. A. 43, 1468 (2012)

R. Voigt, L. Eldoky, H. Chiou, AFS Trans. 94, 645 (1986)

N. Wade, Y. Ueda, Trans. Iron Steel Inst. Jpn. 21, 119 (1981)

A. Basso, R. Martinez, J. Sikora, Mater. Sci. Technol. 23, 1321 (2007)

A. Basso, R. Martinez, J. Sikora, J. Alloy. Compd. 509, 9884 (2011)

T. Kobayashi, S. Yamada, Metall. Mater. Trans. A 27, 1961 (1996)

S.K. Putatunda, P.K. Gadicherla, Mater. Sci. Eng. A 268, 15 (1999)

B. Kovacs, J. Heat. Treat. 5, 55 (1987)

B.V. Kovacs Sr., Mod. Cast. 80, 38 (1990)

A. Nofal, J. Metal. Eng. 2, 1 (2013)

A. Nofal, L. Jekova, J. Chem. Technol. Metall. 44, 213 (2009)

J. Olawale, K. Oluwasegun, Mater. Perform. Charac. 5, 289 (2016)

S.K. Putatunda, P.K. Gadicherla, J. Mater. Eng. Perform. 9, 193 (2000)

P.P. Rao, S.K. Putatunda, Metall. Mater. Trans. A 28, 1457 (1997)

P.P. Rao, S.K. Putatunda, Metall. Mater. Trans. A 29, 3005 (1998)

B. Wang, G.C. Barber, F. Qiu, Q. Zou, H. Yang, J. Mater. Res. Technol-JMRT 9, 1054 (2020)

C. Wang, R. Liu, S. Li, C. Gu, X. Du, Y. Sun, J. Tian, Mater. Sci. Technol. 35, 1329 (2019)

M. Yalcin, B. Cetin, K. Davut, Acta Phys. Pol. A 135, 829–833 (2019)

Y. Sahin, V. Kilicli, Wear 271, 2766 (2011)

P. Sellamuthu, D. Samuel, D. Dinakaran, V. Premkumar, Z. Li, S. Seetharaman, Metals 8, 53 (2018)

H. Zhang, Y.X. Wu, Q.J. Li, X. Hong, Wear 406, 156 (2018)

X. Wang, Y. Du, B. Liu, B. Jiang, Mater. Sci. Eng. A 804, 140513 (2020)

M. Baydogan, H. Cimenoglu, Scan. J. Metall. 30, 391 (2001)

M.C. Cakir, A. Bayram, Y. Isik, B. Salar, Mater. Sci. Eng. A 407, 147 (2005)

Y. Du, X. Gao, X. Wang, X. Wang, Y. Ge, B. Jiang, Wear 456, 203396 (2020)

J.O. Olawale, S.A. Ibitoye, K.M. Oluwasegun, M.D. Shittu, A.P.I. Popoola, Int. J. Metalcast. 11, 568–580 (2017). https://doi.org/10.1007/s40962-016-0114-7

A. Basso, J. Sikora, R. Martinez, Fatigue Fract. Eng. Mater. Struct. 36, 650 (2013)

M. Soliman, H. Ibrahim, A. Nofal, H. Palkowski, Int. J. Cast. Metals Res. 29, 79 (2016)

S. Yazdani, R. Elliott, Mater. Sci. Technol. 15, 531 (1999)

ASTM 975–13, Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation (ASTM International, USA, 2003).

C. Roberts, J. Metals 5, 203 (1953)

R.C. Voigt, C. Loper, J. Heat. Treat. 3, 291 (1984)

J. Aranzabal, I. Gutierrez, J. Rodriguez-Ibabe, J. Urcola, Metall. Mater. Trans. A 28, 1143 (1997)

M. Bahmani, R. Elliott, N. Varahram, J. Mater. Sci. 32, 4783 (1997)

A. Refaey, N. Fatahalla, J. Mater. Sci. 38, 351 (2003)

S. Murcia, M. Paniagua, E. Ossa, Mater. Sci. Eng. A 566, 8 (2013)

O. Erić, D. Rajnović, S. Zec, L. Sidjanin, M.T. Jovanović, Mater. Charact. 57, 211 (2006)

J. Aranzabal, I. Gutierrez, J.M. Rodriguezibabe, J.J. Urcola, Mater. Sci. Technol. 8, 263 (1992)

J. Aranzabal, I. Gutierrez, J.J. Urcola, Mater. Sci. Technol. 10, 728 (1994)

S. Yazdani, R. Elliott, Mater. Sci. Technol. 15, 541 (1999)

S. Yazdani, R. Elliott, Mater. Sci. Technol. 15, 885 (1999)

S. Yazdani, R. Elliott, Mater. Sci. Technol. 15, 896 (1999)

G. Artola, I. Gallastegi, J. Izaga, M. Barreña, A. Rimmer, Int. J. Metalcast. 11, 131–135 (2017). https://doi.org/10.1007/s40962-016-0085-8

A.S. Benam, China Foundry 12, 54 (2015)

P. Shanmugam, P.P. Rao, K.R. Udupa, N. Venkataraman, J. Mater. Sci. 29, 4933 (1994)

C. Yang, X. Cui, C. Liu, Mater. Sci. Technol. 34, 261 (2018)

O. Eric, L. Sidjanin, Z. Miskovic, S. Zec, M. Jovanovic, Mater. Lett. 58, 2707 (2004)

M. Górny, G. Angella, E. Tyrała, M. Kawalec, S. Paź, A. Kmita, Met. Mater. Int. 25, 956 (2019)

Acknowledgements

The authors would like to thank Gazi University Scientific Research Projects Coordination Unit for financial support of the study.

Funding

This work was supported by the Gazi University Scientific Research Projects Coordination Unit under Grant numbers 07/2020-17 and 07/2020-19.

Author information

Authors and Affiliations

Contributions

AU was involved in experimental studies (casting and heat treatments), investigation, creating figures, and writing. OS was involved in experimental studies (mechanical tests and microstructural characterization), investigation, creating figures, and writing. BN was involved in experimental studies (XRD analysis and high-carbon retained austenite calculation), investigation, creating figures, and writing. VK was involved in conceptualization, writing and editing, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare to have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uyar, A., Sahin, O., Nalcaci, B. et al. Effect of Austempering Times on the Microstructures and Mechanical Properties of Dual-Matrix Structure Austempered Ductile Iron (DMS-ADI). Inter Metalcast 16, 407–418 (2022). https://doi.org/10.1007/s40962-021-00617-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00617-4