Abstract

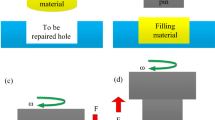

Radial additive friction stir repairing (R-AFSR) assisted by stationary shoulder was put forward in the present study, which can be employed to repair the mechanical hole out of dimension tolerance of AZ31 magnesium alloy sheet. The results show that the stationary shoulder has sealed-barrier, heat-sink and extra-forging effects. The heat-sink effect improves the microstructure uniformity along the stir zone (SZ) thickness and the surface appearance of repaired hole, and the sealed-barrier and extra-forging effects eliminate the super-fine grain band in the SZ. Therefore, these three effects improve the formation quality of repaired region, thereby enhancing the mechanical properties of repaired mechanical hole compared with conventional R-AFSR. The tensile and compressive shear strengths of the repaired hole by stationary shoulder R-AFSR both increase first and then decrease when the rotating speed changes from 1200 to 1800 rpm, and these maximum values, respectively, reach 190 ± 3 MPa and 64.5 ± 2 MPa at 1400 rpm. The addition of stationary shoulder during R-AFSR can obtain a higher-quality repaired hole and broaden the repairing process window.

Similar content being viewed by others

References

J.W. Lee, Weld. Res. Suppl. 54, 409 (1975)

X. Meng, Y. Huang, J. Cao, J. Shen, J.F. dos Santos, Prog. Mater. Sci. 115, 100706 (2021)

Y. Huang, X. Meng, Y. Xie, L. Wan, Z. Lv, J. Cao, J. Feng, Compos. Part. A Appl. Sci. Manuf. 105, 235 (2018)

H. Liu, H. Zhang, T. Nonferr, Met. Soc. 19, 563 (2009)

L. Zhou, D. Liu, K. Nakata, T. Tsumura, H. Fujii, K. Ikeuchi, Y. Michishita, Y. Fujiya, M. Morimoto, Sci. Technol. Weld. Joining 17, 649 (2013)

K.P. Mehtal, R. Patel, Key Eng. Mater. 821, 215 (2019)

K.P. Mehta, R. Patel, H. Vyas, S. Memon, P. Vilaça, Manuf. Lett. 23, 67 (2020)

H. Zhou, K.P. Mehta, Vacuum 18, 109445 (2020)

L. Cui, X. Yang, D. Wang, X. Hou, J. Cao, W. Xu, Mater. Sci. Eng. A 611, 15 (2014)

B. Du, Z. Sun, X. Yang, L. Cui, J. Song, Z. Zhang, Mater. Sci. Eng. A 654, 21 (2015)

B. Han, Y. Huang, S. Lv, L. Wan, J. Feng, G. Fu, Mater. Des. 51, 25 (2013)

M. Reimann, T. Gartner, U. Suhuddin, J. Göbel, J.F. dos Santos, J. Mater. Process. Technol. 237, 12 (2016)

R. Huang, S. Ji, X. Meng, Z. Li, J. Mater. Process. Technol. 255, 765 (2018)

S. Ji, X. Meng, Y. Zeng, L. Ma, S. Gao, Mater. Des. 97, 175 (2016)

R.J. Griffiths, D.T. Petersen, D. Garcia, H.Z. Yu, Appl. Sci. 9, 3486 (2019)

R. Ranjan, A.R. Khan, C. Parikh, R. Jain, R.P. Mahto, S. Pal, S.K. Pal, D. Chakravarty, J. Manuf. Process. 22, 237 (2016)

A. Barbini, J. Carstensen, J.F. dos Santos, J. Mater. Sci. Technol. 34, 119 (2018)

S. Niu, B. Wu, L. Ma, Z. Lv, D. Yan, Int. J. Adv. Manuf. Technol. 97, 2461 (2018)

S. Sinhmar, D.K. Dwivedi, J. Mater. Process. Technol. 277, 116482 (2020)

Q. Song, Q. Wen, S. Ji, X. Meng, Int. J. Adv. Manuf. Technol. 105, 4761 (2019)

S. Ji, Q.Y. Shi, L.G. Zhang, A.L. Zou, S.S. Gao, Z. Lv, Comput. Mater. Sci. 63, 218 (2012)

S. Lee, H.J. Ham, S.Y. Kwon, S.S. Kim, C.M. Suh, Int. J. Thermophys 34, 2343 (2013)

J. Liu, Z. Cui, L. Ruan, AIP Conf. Proc. 908, 1319 (2007)

B.R. Sunil, G.P.K. Redd, A.S.N. Mounika, P.N. Sree, P.R. Pinneswari, I. Ambica, R.A. Babu, P. Amarnadh, J. Magnes. Alloy. 3, 330 (2015)

F. Bakhtiari, A. Argesi, S.E. Shamsipur, Mirsalehi. Acta. Metall. Sin. Engl. Lett. 31, 1183 (2018)

W.F. Xu, Y.X. Luo, M.W. Fu, Mater. Charact. 138, 48 (2018)

W.Y. Li, T. Fu, L. Hütsch, J. Hilgert, F.F. Wang, J.F. dos Santos, N. Huber, Mater. Des. 64, 714 (2014)

R. Xin, D. Liu, X. Shu, B. Li, X. Yang, Q. Liu, J. Alloys Comp. 64, 670 (2016)

S.B. Aziz, M.W. Dewan, D.J. Huggett, M.A. Wahab, A.M. Okeil, T. WarrenLiao, Acta. Metall. Sin. Engl. Lett. 29, 869 (2016)

Y. Chao, X.H. Chen, P. Peng, T. Tu, A. Atrens, F.S. Pan, Acta. Metall. Sin. Engl. Lett. 33, 53 (2020)

Y. Huang, Y. Wang, L. Wan, H. Liu, J. Shen, JFs. dos Santos, L. Zhou, J. Feng, Int. J. Adv. Manuf. Technol. 87, 1115 (2016)

S.D. Ji, Q. Wen, Z.W. Li, J. Mater. Sci. Technol. 48, 23 (2020)

Q. Song, Z. Ma, S. Ji, Q. Li, L. Wang, R. Li, Acta. Metall. Sin. Engl. Lett. 32, 1261 (2019)

Acknowledgement

This work is supported by the National Natural Science Foundation of China (No. 51874201).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Zuo, YY., Liu, H., Gong, P. et al. Radial Additive Friction Stir Repairing of Mechanical Hole Out of Dimension Tolerance of AZ31 Magnesium Alloy Assisted by Stationary Shoulder: Process and Mechanical Properties. Acta Metall. Sin. (Engl. Lett.) 34, 1345–1360 (2021). https://doi.org/10.1007/s40195-021-01223-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01223-3