Abstract

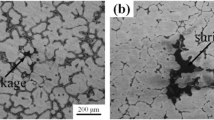

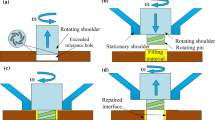

In order to repair the varied-shaped volume defect adjacent to metal structure surface, passive filling friction stir repairing using an external stationary shoulder was put forward. The material flow model during the repairing process was established to explain why the stationary shoulder improves the quality of repaired region. The relation between microstructures and microhardnesses was attained. The results reflect that the stationary shoulder can transfer more materials into the stir zone (SZ) and absorb more heat generated in the SZ. These effects are beneficial to not only avoiding the hole defect in the SZ, but also greatly refining the grain and then heightening the microhardness in the SZ top region. Therefore, the addition of the stationary shoulder plays an important positive role on the repairing process, especially when the extra filling material is used.

Similar content being viewed by others

References

Wang FF, Li WY, Shen J, Wen Q, dos Santos JF (2018) Improving the weld formability by a novel dual-rotation bobbin tool friction stir welding. J Mater Sci Technol 34(1):135–139

Huang YX, Wan L, Lv SX, Feng JC (2013) Novel design of tool for joining hollow extrusion by friction stir welding. Sci Technol Weld Join 18(3):239–246

Xu W, Liu J, Luan G, Dong C (2009) Temperature evolution, microstructure and mechanical properties of friction stir welded thick 2219-O aluminum alloy joints. Mater Des 30:1886–1893

Davies PS, Wynne BP, Rainforth WM, Thomas MJ, Threadgill PL (2011) Development of microstructure and crystallographic texture during stationary shoulder friction stir welding of Ti-6Al-4V. Metall Mater Trans A. 42:2278–2289

Liu HJ, Li JQ, Duan WJ (2013) Friction stir welding characteristics of 2219-T6 aluminum alloy assisted; by external non-rotational shoulder. Int J Adv Manuf Technol 64(9–12):1685–1694

Li ZW, Yue YM, Ji SD, Chai P, Zhou ZL (2016) Joint features and mechanical properties of friction stir lap welded alclad 2024 aluminum alloy assisted by external stationary shoulder. Mater Des 90:238–247

Maltin CA, Nolton LJ, Scott JL, Toumpis AL, Galloway AM (2014) The potential adaptation of stationary shoulder friction stir welding technology to steel. Mater Des 64:614–624

Zhou Z, Yue Y, Ji S, Li Z, Zhang L (2017) Effect of rotating speed on joint morphology and lap shear properties of stationary shoulder friction stir lap welded 6061-T6 aluminum alloy. Int J Adv Manuf Technol 88:2135–2141

Li D, Yang X, Cui L, He F, Zhang X (2015) Investigation of stationary shoulder friction stir welding of aluminum alloy 7075-T651. J Mater Process Technol 222:391–398

Wu H, Chen YC, Strong D, Prangnell P (2015) Stationary shoulder FSW for joining high strength aluminum alloys. J Mater Process Technol 221:187–196

Park SY, Kim WJ, Mater J (2016) Difference in the hot compressive behavior and processing maps between the as-cast and homogenized Al-Zn-Mg-Cu (7075) alloys. J Mater Sci Technol 32:660–670

Ji SD, Meng XC, Li ZW, Ma L, Gao SS (2016) Investigation of vertical compensation friction stir-welded 7N01-T4 aluminum alloy. Int J Adv Manuf Technol 84:2391–2399

Liu HJ, Zhang HJ (2013) Study of hybrid welding repair process of friction stir welding grove defect. Sci Technol Weld Join 17:169–173

Cui L, Yang X, Wang D, Hou X, Gao J (2014) Friction taper plug welding for S355 steel in underwater wet conditions: welding performance, microstructures and mechanical properties. Mater Sci Eng A 611:15–28

Du B, Sun Z, Yang X, Cui L, Song JL, Zhang ZP (2016) Characteristics of friction plug welding to 10mm thick AA2219-T87 sheet: weld formation, microstructure and mechanical property. Mater Sci Eng A 654:21–29

Huang T, Sato YS, Kokawa H, Miles MP, Kohkonen K, Siemssen B, Steel RJ, Packer S (2009) Microstructural evolution of DP980 steel during friction bit joining. Metall Mater Trans A. 40:2994–3000

Huang YX, Han B, Tian Y, Liu HJ, Lv SX, Feng JC, Leng JS, Li Y (2011) New technique of filling friction stir welding. Sci Technol Weld Join 16:497–501

Ji SD, Meng XC, Zeng Y, Ma L, Gao SS (2016) New technique for eliminating keyhole by active-passive filling friction stir repairing. Mater Des 97:175–182

Huang RF, Ji SD, Meng XC (2018) Drilling-filling friction stir repairing of AZ31-B magnesium alloy. J Mater Process Technol 255:765–772

Yue YM, Zhou ZL, Ji SD, Zhang J, Li ZW (2017) Effect of welding speed on joint feature and mechanical properties of friction stir lap welding assisted by external stationary shoulders. Int J Adv Manuf Technol 89:1691–1698

Xue P, Xie GM, Xiao BL, Ma ZY, Geng L (2010) Effect of heat input conditions on microstructure and mechanical properties of friction-stir-welded pure copper. Metall Mater Trans A. 41:2010–2021

Liu ZL, Cui HT, Ji SD, Xu MQ, Meng XC (2016) Improving joint features and mechanical properties of pinless fiction stir welding of alcald 2A12-T4 aluminum alloy. J Mater Sci Technol 32:1372–1377

Ji SD, Li ZW, Zhou ZL, Wu BS (2017) Effect of thread and rotating speed on material flow behavior and mechanical properties of friction stir lap welding joints. J Mater Eng Perform 26(10):5085–5096

Li WY, Fu T, Hütsch L, Hilgert J, Wang FF, dos Santos JF, Huber N (2014) Effects of tool rotational and welding speed on microstructure and mechanical properties of bobbin-tool friction-stir welded Mg AZ31. Mater Des 64:714–720

Yang J, Xiao BL, Wang D, Ma ZY (2010) Effects of heat input on tensile properties and fracture behavior of friction stir welded Mg–3Al–1Zn alloy. Mater Sci Eng A 527:708–714

Yang J, Wang D, Xiao BL, Ni DR, Ma ZY (2013) Effects of rotation rates on microstructure, mechanical properties, and fracture behavior of friction stir-welded (FSW) AZ31 magnesium alloy. Metall Mater Trans A 44:517–530

Chang CI, Du XH, Huang JC (2007) Achieving ultrafine grain size in Mg–Al–Zn alloy by friction stir processing. Scr Mater 57:209–212

Chowdhury SM, Chen DL, Bhole SD, Cao X (2010) Tensile properties of a friction stir welded magnesium alloy: effect of pin tool thread orientation and weld pitch. Mater Sci Eng A 527:6064–6075

Wang XH, Wang KS (2006) Microstructure and properties of friction stir butt-welded AZ31 magnesium alloy. Mater Sci Eng A 431:114–117

Chang CI, Lee CJ, Huang JC (2004) Relationship between grain size and Zener–Holloman parameter during friction stir processing in AZ31 Mg alloys. Scr Mater 51:509–514

Afrin N, Chen DL, Cao X, Jahazi M (2008) Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy. Mater Sci Eng A 472:179–186

Funding

This work is supported by the National Natural Science Foundation of China (No. 51705339), the China Postdoctoral Science Foundation (No.2016M590821), and the Guangdong Provincial Key Laboratory of Advanced Welding Technology for Ships (No.2017B030302010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, S., Wu, B., Ma, L. et al. Passive filling friction stir repairing AZ31-B magnesium alloy by external stationary shoulder. Int J Adv Manuf Technol 97, 2461–2468 (2018). https://doi.org/10.1007/s00170-018-2130-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2130-7