Abstract

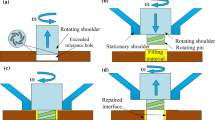

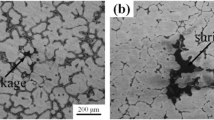

Radial-additive friction stir repairing (R-AFSR) was proposed to repair exceeded tolerance holes. Here, AZ31 Mg alloys were selected as the primary research object. Good metallurgical bonding appeared in the repaired zones due to atom diffusion induced by thermo-mechanical behaviors. The diameter of the exceeded tolerance hole was reduced from 10 to 8 mm. The stir zone and partial thermo-mechanically affected zone were characterized by fine and equiaxed grains. The average grain size in the stir zone was less than 10 μm, attributing to high microhardness values. A high-quality repaired joint with the maximum tensile strength of 183 MPa was achieved, equivalent to 93.8% of the joint with the standard hole for AZ31 Mg alloys. Compressive shear strength and compression rate of the repaired joint reached 58.4 MPa and 26.1%, up to 75% and 74.6% of the joint with the standard hole. The fracture surface morphologies exhibited the typical ductile fracture. Therefore, R-AFSR has great prospects to repair the exceeded tolerance holes.

Similar content being viewed by others

References

Meng X, Xu Z, Huang Y, Xie Y, Wang Y, Wan L, Lv Z, Cao J (2018) Interface characteristic and tensile property of friction stir lap welding of dissimilar aircraft 2060-T8 and 2099-T83 Al–Li alloys. Int J Adv Manuf Technol 94:1253–1261. https://doi.org/10.1007/s00170-017-0996-4

Guan M, Wang Y, Huang Y et al (2019) Non-weld-thinning friction stir welding. Mater Lett 255:126506. https://doi.org/10.1016/j.matlet.2019.126506

Huang R, Ji S, Meng X, Li Z (2018) Drilling-filling friction stir repairing of AZ31B magnesium alloy. J Mater Process Technol 255:765–772. https://doi.org/10.1016/j.jmatprotec.2018.01.019

Kim YG, Fujii H, Tsumura T et al (2006) Three defect types in friction stir welding of aluminum die casting alloy. Mater Sci Eng A 415:250–254. https://doi.org/10.1016/j.msea.2005.09.072

Li L, Liu Z, Snow M (2006) Effect of defects on fatigue strength of GTAW repaired cast aluminum alloy. Weld J 85:264

Shankar K, Wu W (2002) Effect of welding and weld repair on crack propagation behaviour in aluminium alloy 5083 plates. Mater Des 23:201–208. https://doi.org/10.1016/S0261-3069(01)00059-0

Tu JF, Paleocrassas AG (2011) Fatigue crack fusion in thin-sheet aluminum alloys AA7075-T6 using low-speed fiber laser welding. J Mater Process Technol 211:95–102. https://doi.org/10.1016/j.jmatprotec.2010.09.001

Huang Y, Meng X, Xie Y et al (2018) Friction stir welding/processing of polymers and polymer matrix composites. Compos A Appl Sci Manuf 105:235–257. https://doi.org/10.1016/j.compositesa.2017.12.005

Huang Y, Huang T, Wan L et al (2019) Material flow and mechanical properties of aluminum-to-steel self-riveting friction stir lap joints. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2018.08.011

Huang Y, Xie Y, Meng X et al (2018) Numerical design of high depth-to-width ratio friction stir welding. J Mater Process Technol 252:233–241. https://doi.org/10.1016/j.jmatprotec.2017.09.029

Huang Y, Wang Y, Wan L et al (2016) Material-flow behavior during friction-stir welding of 6082-T6 aluminum alloy. Int J Adv Manuf Technol 87:1115–1123. https://doi.org/10.1007/s00170-016-8603-7

Zhou L, Li GH, Liu CL, Wang J, Huang YX, Feng JC, Meng FX (2017) Effect of rotation speed on microstructure and mechanical properties of self-reacting friction stir welded Al-Mg-Si alloy. Int J Adv Manuf Technol 89:3509–3516. https://doi.org/10.1007/s00170-016-9318-5

Xu WF, Luo YX, Fu MW (2018) Microstructure evolution in the conventional single side and bobbin tool friction stir welding of thick rolled 7085-T7452 aluminum alloy. Mater Charact 138:48–55. https://doi.org/10.1016/j.matchar.2018.01.051

Ji S, Meng X, Ma L et al (2015) Vertical compensation friction stir welding assisted by external stationary shoulder. Mater Des 68:72–79. https://doi.org/10.1016/j.matdes.2014.12.009

Ji SD, Meng XC, Li ZW, Ma L, Gao SS (2016) Investigation of vertical compensation friction stir-welded 7 N01-T4 aluminum alloy. Int J Adv Manuf Technol 84:2391–2399. https://doi.org/10.1007/s00170-015-7904-6

Ji S, Meng X, Xing J et al (2016) Vertical compensation friction stir welding of 6061-T6 aluminum alloy. High Temp Mater Process 35:843–851. https://doi.org/10.1515/htmp-2015-0063

Liu H, Zhang H (2009) Repair welding process of friction stir welding groove defect. Trans Nonferrous Metals Soc China 19:563–567. https://doi.org/10.1016/S1003-6326(08)60313-1

Cui L, Yang X, Wang D et al (2014) Friction taper plug welding for S355 steel in underwater wet conditions: welding performance, microstructures and mechanical properties. Mater Sci Eng A 611:15–28. https://doi.org/10.1016/j.msea.2014.04.087

Du B, Sun Z, Yang X et al (2016) Characteristics of friction plug welding to 10 mm thick AA2219-T87 sheet: Weld formation, microstructure and mechanical property. Mater Sci Eng A 654:21–29. https://doi.org/10.1016/j.msea.2015.12.019

Lim YC, Squires L, Pan TY et al (2015) Study of mechanical joint strength of aluminum alloy 7075-T6 and dual phase steel 980 welded by friction bit joining and weld-bonding under corrosion medium. Mater Des 69:37–43. https://doi.org/10.1016/j.matdes.2014.12.043

Ji SD, Meng XC, Huang RF et al (2016) Microstructures and mechanical properties of 7 N01-T4 aluminum alloy joints by active-passive filling friction stir repairing. Mater Sci Eng A 664. https://doi.org/10.1016/j.msea.2016.03.131

Ji S, Meng X, Zeng Y et al (2016) New technique for eliminating keyhole by active-passive filling friction stir repairing. Mater Des 97:175–182. https://doi.org/10.1016/j.matdes.2016.02.088

Ren J-G, Wang L, Xu D-K, Xie LY, Zhang ZC (2017) Analysis and modeling of friction stir processing-based crack repairing in 2024 aluminum alloy. Acta Metall Sin 30:228–237. https://doi.org/10.1007/s40195-016-0489-8

Liu HJ, Zhang HJ (2012) Study of hybrid welding repair process of friction stir welding grove defect. Sci Technol Weld Join 17:169–173. https://doi.org/10.1179/136217111X13218932822646

Zhou L, Liu D, Nakata K et al (2012) New technique of self-refilling friction stir welding to repair keyhole. Sci Technol Weld Join 17:649–655. https://doi.org/10.1179/1362171812Y.0000000058

Huang YX, Han B, Tian Y et al (2011) New technique of filling friction stir welding. Sci Technol Weld Join 16:497–501. https://doi.org/10.1179/1362171811Y.0000000032

Miles MP, Feng Z, Kohkonen K et al (2010) Spot joining of AA 5754 and high strength steel sheets by consumable bit. Sci Technol Weld Join 15:325–330. https://doi.org/10.1179/136217110X12707333260491

Li WY, Fu T, Hütsch L et al (2014) Effects of tool rotational and welding speed on microstructure and mechanical properties of bobbin-tool friction-stir welded Mg AZ31. Mater Des 64:714–720. https://doi.org/10.1016/j.matdes.2014.07.023

Chen J, Fujii H, Sun Y et al (2017) Optimization of mechanical properties of fine-grained non-combustive magnesium alloy joint by asymmetrical double-sided friction stir welding. J Mater Process Technol 242:117–125. https://doi.org/10.1016/j.jmatprotec.2016.11.021

Niu S, Wu B, Ma L, Lv Z, Yan D (2018) Passive filling friction stir repairing AZ31-B magnesium alloy by external stationary shoulder. Int J Adv Manuf Technol 97:2461–2468. https://doi.org/10.1007/s00170-018-2130-7

Acknowledgment

This work is supported by the National Natural Science Foundation of China (No.51874201) and the Aeronautical Science Foundation of China (No. 20171125002).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qi, S., Wen, Q., Ji, S. et al. New technique of radial-additive friction stir repairing for exceeded tolerance holes. Int J Adv Manuf Technol 105, 4761–4771 (2019). https://doi.org/10.1007/s00170-019-04619-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04619-9