Abstract

The feasibility of producing direct reduced iron from pellets made up of mill scale by utilizing coal as a reductant has been investigated. The chemical and morphological characterization studies reveal that the mill scale contains around 71% Fe and comprises of a mixture of iron oxide phases such as magnetite and hematite with a little amount of wustite. The reduction study of the mill scale pellets has been carried out using the statistical design of experimental approach employing the response surface methodology. Under optimum conditions such as a temperature of 1246 °C, a time of 1.52 h, and coal-to-mill scale ratio of 0.58, around 88–89% metallization is obtained. Similarly, around 84% of metallization can be achieved at a temperature around 1150 °C, time of about 1.5 h with coal-to-mill scale ratio of 0.59. The characterization studies of the reduced pellets using X-ray diffraction and optical microscopy show the sequential growth of the metallic phase as the reducing parameters are increased. The properties of the mill scale pellets are found to match the desired specification for the direct reduction process, and the reduction behavior of the pellets as a function of temperature, time, and coal-to-mill scale ratio suggests that iron making from mill scale through this route is a promising process.

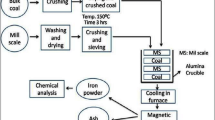

Graphical Abstract

Similar content being viewed by others

References

Sista K S, Dwarapudi S, and Nerune V P, ISIJ Int59 (2019) 787.

Steel-Report-Mar-2018, https://www.ibef.org/download/Steel-Report-Mar-2018.pdf (2018). Accessed 27 Jun 2019.

Mazumdar R, National Steel Policy 2017 to focus spending on infrastructure, construction, in Econ. Times (2017). Accessed 17 Apr 2018.

Martín M I, López F A, and Torralba J M, Ironmak Steelmak39 (2012) 155.

Gaballah N M, Zikry A F, Khalifa M G, Farag A B, El-Hussiny N A, and Shalabi M E H, Open J Inorg Non-Met Mater 03 (2013) 23.

Paswan D, Malathi M, Minj R K, and Bandhyopadhayay D, Mill Scale: A Potential Raw Material for Iron and Steel Making, Steelworld (2015).

Ray N, Nayak D, Dash N, and Rath S S, Clean Technol Environ Policy20 (2018) 1761.

Gao L, Liu Z, Pan Y, Ge Y, Feng C, Chu M, and Tang J, Min Metall Explor36 (2019) 375.

Sunil S R, Rayapudi V, and Dhawan N, Min Metall Explor. (2019).

Ye Q, Zhu H, Peng J, Srinivasa Kannan C, Chen J, Dai L, and Liu P, Metall Mater Trans B44 (2013) 1478.

Ye Q, Zhu H, Zhang L, Ma J, Zhou L, Liu P, Chen J, Chen G, and Peng J, J Alloys Compd613 (2014) 102.

Mechachti S, Benchiheub O, Serrai S, and Shalabi M E H, Int J Sci Eng Res4 (2013) 1467.

Cho S, Met Mater Int14 (2008) 193.

Benchiheub O, Mechachti S, Serrai S, and Khalifa M G, J Mater Environ Sci1 (2010) 267.

Joshi C, and Dhokey N B, Trans Indian Inst Met68 (2015) 31.

Sen R, Dehiya S, Pandel U, and Banerjee M K, Procedia Earth Planet Sci11 (2015) 8.

Saberifar S, Jafari F, Kardi H, Jafarzadeh M A, and Mousavi S, J Adv Mater Process2 (2014) 73.

Eissa M, Ahmed A, and El-Fawkhry M, J Metall2015 (2015) 1.

Nikai I, and Garbers-Craig A M, Miner Process Extr Metall Rev37 (2016) 42.

Chesters JH, Iron Steel Inst Lond (1973) 553.

Krishnamurthy L, Sridhara B K, and Budan D A, Mater Manuf Process22 (2007) 903.

Montgomery D C, Design and Analysis of Experiments, 8th Edition. John Wiley & Sons, Hoboken, NJ (2012).

Chatterjee A, Sponge Iron Production by Direct Reduction of Iron Oxide, PHI Learning Private Limited, Delhi (2014).

Monsen B, Thomassen E, Brakstad I, Ringdalen E, and Hoegass P H, in AISTech 2015 Proceedings, Cleveland, Ohio, USA (2015).

Gupta R C, Theory and Laboratory Experiments in Ferrous Metallurgy, Second, Asoke K. Ghosh, PHI Learning Private Limited, Delhi (2015).

Plaul F J, Böhm C, and Schenk J L, J South Afr Inst Min Metall109 (2009) 121.

Acknowledgements

The authors are thankful to the Director, CSIR-IMMT, Bhubaneswar, for his permission to publish this paper and the Ministry of Steel, Government of India (Grant No. F. No. 11(12)/GBS/2014-TW), for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nayak, D., Roy, S.K., Dash, N. et al. Investigation on the Coal-Based Direct Reduction of Mill Scale Pellets: Statistical Modeling and Characterization Studies. Trans Indian Inst Met 73, 691–701 (2020). https://doi.org/10.1007/s12666-020-01889-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01889-w