Abstract

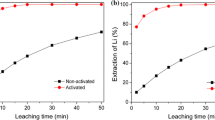

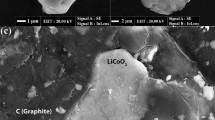

Lithium recovery from spent lithium-ion batteries (LIBs) have attracted extensive attention due to the skyrocketing price of lithium. The medium-temperature carbon reduction roasting was proposed to preferential selective extraction of lithium from spent Li-CoO2 (LCO) cathodes to overcome the incomplete recovery and loss of lithium during the recycling process. The LCO layered structure was destroyed and lithium was completely converted into water-soluble Li2CO3 under a suitable temperature to control the reduced state of the cobalt oxide. The Co metal agglomerates generated during medium-temperature carbon reduction roasting were broken by wet grinding and ultrasonic crushing to release the entrained lithium. The results showed that 99.10% of the whole lithium could be recovered as Li2CO3 with a purity of 99.55%. This work provided a new perspective on the preferentially selective extraction of lithium from spent lithium batteries.

Similar content being viewed by others

References

Y.C. Lyu, X. Wu, K. Wang, et al., An overview on the advances of LiCoO2 cathodes for lithium-ion batteries, Adv. Energy Mater., 11(2021), No. 2, art. No. 2000982.

T. Fujita, H. Chen, K.T. Wang, et al., Reduction, reuse and recycle of spent Li-ion batteries for automobiles: A review, Int. J. Miner. Metall. Mater., 28(2021), No. 2, p. 179.

J. Lin, J.W. Wu, E.S. Fan, et al., Environmental and economic assessment of structural repair technologies for spent lithiumion battery cathode materials, Int. J. Miner. Metall. Mater., 29(2022), No. 5, p. 942.

Z.X. Tang, H.Q. Ye, X. Ma, and K. Han, Effect of particle micro-structure on the electrochemical properties of LiNi0.8Co0.1Mn0.1O2 cathode material, Int. J. Miner. Metall. Mater., 29(2022), No. 8, p. 1618.

J.P. Qu, Y.S. Zhao, Y.R. Ji, Y.R. Zhu, and T.F. Yi, Approaching high-performance lithium storage materials by constructing Li2ZnTi3O8@LiAlO2 composites, Int. J. Miner. Metall. Mater., 30(2023), No. 4, p. 611.

M.Y. Chen, X.T. Ma, B. Chen, et al., Recycling end-of-life electric vehicle lithium-ion batteries, Joule, 3(2019), No. 11, p. 2622.

J.X. Wang, Q. Zhang, J.Z. Sheng, et al., Direct and green repairing of degraded LiCoO2 for reuse in lithium-ion batteries, Natl. Sci. Rev., 9(2022), No. 8, art. No. nwac097.

M. Yang, R.Y. Bi, J.Y. Wang, R.B. Yu, and D. Wang, Decoding lithium batteries through advanced in situ characterization techniques, Int. J. Miner. Metall. Mater., 29(2022), No. 5, p. 965.

C.W. Liu, J. Lin, H.B. Cao, Y. Zhang, and Z. Sun, Recycling of spent lithium-ion batteries in view of lithium recovery: A critical review, J. Cleaner Prod., 228(2019), p. 801.

X.Y. Guo, X. Cao, G.Y. Huang, Q.H. Tian, and H.Y. Sun, Re-covery of lithium from the effluent obtained in the process of spent lithium-ion batteries recycling, J. Environ. Manage., 198(2017), p. 84.

J. Lin, L. Li, E.S. Fan, et al., Conversion mechanisms of selective extraction of lithium from spent lithium-ion batteries by sulfation roasting, ACS Appl. Mater. Interfaces, 12(2020), No. 16, p. 18482.

J.H. Hou, X.T. Ma, J.Z. Fu, et al., A green closed-loop process for selective recycling of lithium from spent lithium-ion batteries, Green Chem., 24(2022), No. 18, p. 7049.

Y.B. Liu, B.Z. Ma, Y.W. Lü, C.Y. Wang, and Y.Q. Chen, A review of lithium extraction from natural resources, Int. J. Miner. Metall. Mater., 30(2023), No. 2, p. 209.

H. Dang, Z.D. Chang, H.L. Zhou, S.H. Ma, M. Li, and J.L. Xiang, Extraction of lithium from the simulated pyrometallurgical slag of spent lithium-ion batteries by binary eutectic molten carbonates, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1715.

J.X. Wang, Z. Liang, Y. Zhao, et al., Direct conversion of degraded LiCoO2 cathode materials into high-performance LiCoO2: A closed-loop green recycling strategy for spent lithium-ion batteries, Energy Storage Mater., 45(2022), p. 768.

T.N. Lin, Y. Wang, S. Jin, et al., An enhanced strategy based on the pyrolysis of bean dregs for efficient selective recovery of lithium from spent lithium-ion batteries, Green Chem., 24(2022), No. 24, p. 9552.

L.Y. Sun, B.R. Liu, T. Wu, et al., Hydrometallurgical recycling of valuable metals from spent lithium-ion batteries by reductive leaching with stannous chloride, Int. J. Miner. Metall. Mater., 28(2021), No. 6, p. 991.

X.P. Chen, L. Cao, D.Z. Kang, J.Z. Li, T. Zhou, and H.R. Ma, Recovery of valuable metals from mixed types of spent lithium ion batteries. Part II: Selective extraction of lithium, Waste Manage., 80(2018), p. 198.

X.P. Chen, D.Z. Kang, L. Cao, J.Z. Li, T. Zhou, and H.R. Ma, Separation and recovery of valuable metals from spent lithium ion batteries: Simultaneous recovery of Li and Co in a single step, Sep. Purif. Technol., 210(2019), p. 690.

W.G. Lv, Z.H. Wang, X.H. Zheng, et al., Selective recovery of lithium from spent lithium-ion batteries by coupling advanced oxidation processes and chemical leaching processes, ACS Sustainable Chem. Eng., 8(2020), No. 13, p. 5165.

J. Guan, Y.G. Li, Y.G. Guo, et al., Mechanochemical process enhanced cobalt and lithium recycling from wasted lithium-ion batteries, ACS Sustainable Chem. Eng., 5(2017), No. 1, p. 1026.

Y.Z. Jiang, X.P. Chen, S.X. Yan, S.Z. Li, and T. Zhou, Pursuing green and efficient process towards recycling of different metals from spent lithium-ion batteries through Ferro-chemistry, Chem. Eng. J., 426(2021), art. No. 131637.

X.P. Chen, D.Z. Kang, J.Z. Li, T. Zhou, and H.R. Ma, Gradient and facile extraction of valuable metals from spent lithium ion batteries for new cathode materials re-fabrication, J. Hazard. Mater., 389(2020), art. No. 121887.

Y.F. Zheng, P.H. Shao, L.M. Yang, et al., Gas exchange-driven carbothermal reduction for simultaneous lithium extraction from anode and cathode scraps, Resour. Conserv. Recycl., 188(2023), art. No. 106696.

Z.M. Yan, A. Sattar, and Z.S. Li, Priority Lithium recovery from spent Li-ion batteries via carbothermal reduction with water leaching, Resour. Conserv. Recycl., 192(2023), art. No. 106937.

N. Wei, Y.Q. He, G.W. Zhang, et al., Recycling of valuable metals from spent lithium-ion batteries by self-supplied reductant roasting, J. Environ. Manage., 329(2023), art. No. 117107.

R. Morina, D. Merli, P. Mustarelli, and C. Ferrara, Lithium and cobalt recovery from lithium-ion battery waste via functional ionic liquid extraction for effective battery recycling, ChemElectroChem, 10(2023), No. 1, art. No. e202201059.

J.L. Zhang, J.T. Hu, W.J. Zhang, Y.Q. Chen, and C.Y. Wang, Efficient and economical recovery of lithium, cobalt, nickel, manganese from cathode scrap of spent lithium-ion batteries, J. Clean. Prod., 204(2018), p. 437.

J.F. Xiao, J. Li, and Z.M. Xu, Novel approach for in situ recovery of lithium carbonate from spent lithium ion batteries using vacuum metallurgy, Environ. Sci. Technol., 51(2017), No. 20, p. 11960.

X.P. Chen, Y. Wang, S.Z. Li, Y.Z. Jiang, Y. Cao, and X. Ma, Selective recycling of valuable metals from waste LiCoO2 cathode material of spent lithium-ion batteries through low-temperature thermochemistry, Chem. Eng. J., 434(2022), art. No. 134542.

F.Y. Zhou, X. Qu, Y.X. Wu, et al., Vacuum pyrolysis of pine sawdust to recover spent lithium ion batteries: The synergistic effect of carbothermic reduction and pyrolysis gas reduction, ACS Sustainable Chem. Eng., 10(2022), No. 3, p. 1287.

W.Q. Wang, Y.C. Zhang, X.G. Liu, and S.M. Xu, A simplified process for recovery of Li and co from spent LiCoO2 cathode using Al foil as the in situ reductant, ACS Sustainable Chem. Eng., 7(2019), No. 14, p. 12222.

P. Xu, C.W. Liu, X.H. Zhang, et al., Synergic mechanisms on carbon and sulfur during the selective recovery of valuable metals from spent lithium-ion batteries, ACS Sustainable Chem. Eng., 9(2021), No. 5, p. 2271.

B.A. Nuraeni, K. Avarmaa, L.H. Prentice, W.J. Rankin, and M.A. Rhamdhani, Recovery of cobalt and lithium by carbothermic reduction of LiCoO2 cathode material: A kinetic study, Metall. Mater. Trans. B, 54(2023), No. 2, p. 602.

M.M. Wang, K. Liu, Z.B. Xu, et al., Selective extraction of critical metals from spent lithium-ion batteries, Environ. Sci. Technol., 57(2023), No. 9, p. 3940.

Y.Q. Tang, H.W. Xie, B.L. Zhang, et al., Recovery and regeneration of LiCoO2-based spent lithium-ion batteries by a carbothermic reduction vacuum pyrolysis approach: Controlling the recovery of CoO or Co, Waste Manage., 97(2019), p. 140.

S. Park, S. Jung, D. Kwon, M. Beak, E.E. Kwon, and K. Kwon, Carbothermic reduction of spent Lithium-Ion batteries using CO2 as reaction medium, Chem. Eng. J., 435(2022), art. No. 135165.

J.K. Mao, J. Li, and Z.M. Xu, Coupling reactions and collapsing model in the roasting process of recycling metals from LiCoO2 batteries, J. Cleaner Prod., 205(2018), p. 923.

J. Li, G.X. Wang, and Z.M. Xu, Environmentally-friendly oxygen-free roasting/wet magnetic separation technology for in situ recycling cobalt, lithium carbonate and graphite from spent LiCoO2/graphite lithium batteries, J. Hazard. Mater., 302(2016), p. 97.

M. Petranikova, A. Miškufová, T. Havlík, O. Forsén, and A. Pehkonen, Cobalt recovery from spent portable lithium accumulators after thermal treatment, Acta Metall. Slovaca, 17(2011), No. 2, p. 106.

Y. Yang, W. Sun, Y.J. Bu, C.Y. Zhang, S.L. Song, and Y.H. Hu, Recovering valuable metals from spent lithium ion battery via a combination of reduction thermal treatment and facile acid leaching, ACS Sustainable Chem. Eng., 6(2018), No. 8, p. 10445.

N. Vieceli, R. Casasola, G. Lombardo, B. Ebin, and M. Petranikova, Hydrometallurgical recycling of EV lithium-ion batteries: Effects of incineration on the leaching efficiency of metals using sulfuric acid, Waste Manage., 125(2021), p. 192.

R. Hossain, U. Kumar, and V. Sahajwalla, Selective thermal transformation of value added cobalt from spent lithium-ion batteries, J. Cleaner Prod., 293(2021), art. No. 126140.

G. Lombardo, B. Ebin, M.R.St.J. Foreman, B.M. Steenari, and M. Petranikova, Chemical transformations in Li-ion battery electrode materials by carbothermic reduction, ACS Sustainable Chem. Eng., 7(2019), No. 16, p. 13668.

Y.C. Lu, A.N. Mansour, N. Yabuuchi, and Y. Shao-Horn, Probing the origin of enhanced stability of “AlPO4” nanoparticle coated LiCoO2 during cycling to high voltages: Combined XRD and XPS studies, Chem. Mater., 21(2009), No. 19, p. 4408.

P.C. Liu, L. Xiao, Y.F. Chen, Y.W. Tang, J. Wu, and H. Chen, Recovering valuable metals from LiNixCoy, Mn1−yO2 cathode materials of spent lithium ion batteries via a combination of reduction roasting and stepwise leaching, J. Alloys Compd., 783(2019), p. 743.

G. Lombardo, B. Ebin, M.R.S.J. Foreman, B.M. Steenari, and M. Petranikova, Incineration of EV lithium-ion batteries as a pretreatment for recycling - Determination of the potential formation of hazardous by-products and effects on metal compounds, J. Hazard Mater., 393(2020), art. No. 122372.

B. Makuza, Q.H. Tian, X.Y. Guo, K. Chattopadhyay, and D.W. Yu, Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review, J. Power Sources, 491(2021), art. No. 229622.

S. Lee, W. Jin, S.H. Kim, et al., Oxygen vacancy diffusion and condensation in lithium-ion battery cathode materials, Angew. Chem. Int. Ed., 58(2019), No. 31, p. 10478.

M.L. Wang, C. Liu, H. Shi, T.Y. Long, C.Y. Zhang, and B. Liu, Facile synthesis of chitosan-derived Maillard reaction productions coated CuFeO2 with abundant oxygen vacancies for higher Fenton-like catalytic performance, Chemosphere, 283(2021), art. No. 131191.

D.S. Kim, J.S. Sohn, C.K. Lee, J.H. Lee, K.S. Han, and Y.I. Lee, Simultaneous separation and renovation of lithium cobalt oxide from the cathode of spent lithium ion rechargeable batteries, J. Power Sources, 132(2004), No. 1–2, p. 145.

B. Makuza, D.W. Yu, Z. Huang, Q.H. Tian, and X.Y. Guo, Dry grinding-carbonated ultrasound-assisted water leaching of carbothermally reduced lithium-ion battery black mass towards enhanced selective extraction of lithium and recovery of high-value metals, Resour. Conserv. Recycl., 174(2021;), art. No. 105784.

Acknowledgements

This work was supported by the Science and Technology Key Project of Anhui Province, China (No. 2022e03020004).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no competing financial interest.

Supplementary Information

12613_2023_2698_MOESM1_ESM.docx

Preferentially selective extraction of lithium from spent LiCoO2 cathodes by medium-temperature carbon reduction roasting

Rights and permissions

About this article

Cite this article

Wei, D., Wang, W., Jiang, L. et al. Preferentially selective extraction of lithium from spent LiCoO2 cathodes by medium-temperature carbon reduction roasting. Int J Miner Metall Mater 31, 315–322 (2024). https://doi.org/10.1007/s12613-023-2698-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2698-2