Abstract

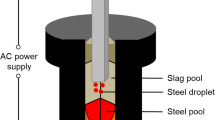

The mass transfer among the multiphase interactions among the steel, slag, lining refractory, and nonmetallic inclusions during the refining process of a bearing steel was studied using laboratory experiments and numerical kinetic prediction. Experiments on the system with and without the slag phase were carried out to evaluate the influence of the refractory and the slag on the mass transfer. A mathematical model coupled the ion and molecule coexistence theory, coupled-reaction model, and the surface renewal theory was established to predict the dynamic mass transfer and composition transformation of the steel, the slag, and nonmetallic inclusions in the steel. During the refining process, Al2O3 inclusions transformed into MgO inclusions owing to the mass transfer of [Mg] at the steel/refractory interface and (MgO) at the slag/refractory interface. Most of the aluminum involved in the transport entered the slag and a small part of the aluminum transferred to lining refractory, forming the Al2O3 or MgO·Al2O3. The slag had a significant acceleration effect on the mass transfer. The mass transfer rate (or the reaction rate) of the system with the slag was approximately 5 times larger than that of the system without the slag. In the first 20 min of the refining, rates of magnesium mass transfer at the steel/inclusion interface, steel/refractory interface, and steel/slag interface were x, 1.1x, and 2.2x, respectively. The composition transformation of inclusions and the mass transfer of magnesium and aluminum in the steel were predicted with an acceptable accuracy using the established kinetic model.

Similar content being viewed by others

References

R.Y. Yin, Metallurgical Process Engineering, Springer, Berlin, Heidelberg, 2011, p. 26.

L.F. Zhang, Non-Metallic Inclusions in Steels: Fundamentals, Metallurgical Industry Press, 2019, p. 320.

L.F. Zhang, Non-metallic Inclussions in Steels: Industrial Practice, Metallurgical Industry Press, Beijing, 2019, p. 482.

C. Gu, J.H. Lian, Y.P. Bao, Q.G. Xie, and S. Munstermann, Microstructure-based fatigue modelling with residual stresses: Prediction of the fatigue life for various inclusion sizes, Int. J. Fatigue, 129(2019), art. No. 105158.

Y.P. Chu, Z.Y. Chen, N. Liu, and L.F. Zhang, Formation and control of spinel inclusions in high-speed heavy rail steel, Iron Steel, 55(2020), No. 1, p. 38.

M.M. Song, C.L. Hu, B. Song, H.Y. Zhu, Z.L. Xue, and R.S. Xu, Effect of Ti-Mg treatment on the impact toughness of heat affected zone in 0.15%C-1.31%Mn steel, Steel Res. Int., 89(2018), No. 3, art. No. 1700355.

J.F. Xu, K.P. Wang, Y. Wang, Z.D. Qu, and X.K. Tu, Effects of ferrosilicon alloy, Si content of steel, and slag basicity on compositions of inclusions during ladle furnace refining of Al-killed steel, J. Iron Steel Res. Int., 27(2020), No. 9, p. 1011.

S.J. Li, G.G. Cheng, Z.Q. Miao, L. Chen, and X.Y. Jiang, Effect of slag on oxide inclusions in carburized bearing steel during industrial electroslag remelting, Int. J. Miner. Metall. Mater., 26(2019), No. 3, p. 291.

J.H. Shin and J.H. Park, Effect of CaO/Al2O3 ratio of ladle slag on formation behavior of inclusions in Mn and V alloyed steel, ISIJ Int., 58(2018), No. 1, p. 88.

Y. Ren and L.F. Zhang, Thermodynamic model for prediction of slag-steel-inclusion reactions of 304 stainless steels, ISIJ Int., 57(2017), No. 1, p. 68.

Y. Ren, L.F. Zhang, W. Fang, S.J. Shao, J. Yang, and W.D. Mao, Effect of slag composition on inclusions in Si-deoxidized 18Cr-8Ni stainless steels, Metall. Mater. Trans. B, 47(2016), No. 2, p. 1024.

A. Harada, G. Miyano, N. Maruoka, H. Shibata, and S.Y. Kitamura, Dissolution behavior of Mg from MgO into molten steel deoxidized by Al, ISIJ Int., 54(2014), No. 10, p. 2230.

Y.S. Zou, A. Huang, L.P. Fu, and H.Z. Gu, Effect of lightweight refractories on the cleanness of bearing steels, Ceram. Int., 44(2018), No. 11, p. 12965.

C.Y. Liu, F.X. Huang, J.L. Suo, and X.H. Wang, Effect of magnesia-carbon refractory on the kinetics of MgO·Al2O3 spinel inclusion generation in extra-low oxygen steels, Metall. Mater. Trans. B, 47(2016), No. 2, p. 989.

C.Y. Liu, F.X. Huang, and X.H. Wang, The effect of refining slag and refractory on inclusion transformation in extra low oxygen steels, Metall. Mater. Trans. B, 47(2016), No. 2, p. 999.

M.C. Mantovani, L.R. Moraes, R. Leandro da Silva, E.F. Cabral, E.A. Possente, C.A. Barbosa, and B.P. Ramos, Interaction between molten steel and different kinds of MgO based tundish linings, Ironmaking Steelmaking, 40(2013), No. 5, p. 319.

X.Y. Gao, L. Zhang, X.H. Qu, X.W. Chen, and Y.F. Luan, Effect of interaction of refractories with Ni-based superalloy on inclusions during vacuum induction melting, Int. J. Miner. Metall. Mater., 27(2020), No. 11, p. 1551.

Y.S. Zou, A. Huang, L.P. Fu, P.F. Lian, Y.J. Wang, and H.Z. Gu, Chemical interactions between a calcium aluminate glaze and molten stainless steel containing alumina inclusions, Ceram. Int., 44(2018), No. 1, p. 1099.

M. Song, M. Nzotta, and S.C. Du, Study of the formation of non-metallic inclusions by ladle glaze and the effect of slag on inclusion composition using tracer experiments, Steel Res. Int., 80(2009), No. 10, p. 753.

Y.S. Lee, S.M. Jung, and D.J. Min, Interfacial reaction between Al2O3-SiO2-C refractory and Al/Ti-killed steels, ISIJ Int., 54(2014), No. 4, p. 827.

Y. Li, C.Y. Chen, G.Q. Qin, Z.H. Jiang, M. Sun, and K. Chen, Influence of crucible material on inclusions in 95Cr saw-wire steel deoxidized by Si-Mn, Int. J. Miner. Metall. Mater., 27(2020), No. 8, p. 1083.

J.H. Shin, Y. Chung, and J.H. Park, Refractory-slag-metal-inclusion multiphase reactions modeling using computational thermodynamics: Kinetic model for prediction of inclusion evolution in molten steel, Metall. Mater. Trans. B, 48(2017), No. 1, p. 46.

W.L. Wang, L.W. Xue, T.S. Zhang, L.J. Zhou, H.P. Liu, H.G. Xiao, and Q.B. Sun, The influence of MgO/ZrO2/Al2O3 refractories on the refining process of Ti-containing steel based on kinetic study, Ceram. Int., 46(2020), No. 11, p. 17561.

Y. Zhang, Y. Ren, and L.F. Zhang, Modeling transient evolution of inclusion in Si-Mn-killed steels during the ladle mixing process, Metall. Res. Technol., 114(2017), No. 3, art. No. 308.

Y. Zhang, Y. Ren, and L.F. Zhang, Kinetic study on compositional variations of inclusions, steel and slag during refining process, Metall. Res. Technol., 115(2018), No. 4, art. No. 415.

L.G. Zhu, Y.N. Jia, Z.X. Liu, C.J. Zhang, X.J. Wang, and P.C. Xiao, Mass-transfer model for steel, slag, and inclusions during ladle-furnace refining, High Temp. Mater. Processes, 37(2018), No. 7, p. 665.

A. Harada, N. Maruoka, H. Shibata, and S.Y. Kitamura, A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part 1. basic concept and application, ISIJ Int., 53(2013), No. 12, p. 2110.

S. Ohguchi, D.G.C. Robertson, B. Deo, P. Grieveson, and J.H.E. Jeffes, Simultaneous dephosphorization and desulphurization of molten pig iron, Ironmaking Steelmaking, 11(1984), No. 4, p. 202.

M. Hino and K. Ito, Thermodynamic Data for Steelmaking, Tohoku University Press, Tohoku, 2010, p. 259.

C. Wagner, Thermodynamics of Alloys, Addision-Wesley Pub. Co, Cambridge, 1962, p. 51.

C.H.P. Lupis and J.F. Elliott, Generalized interaction coefficients: Part I: Definitions, Acta Metall., 14(1966), No. 4, p. 529.

G.K. Sigworth and J.F. Elliott, The thermodynamics of liquid dilute iron alloys, Met. Sci., 8(1974), No. 1, p. 298.

H. Suito and R. Inoue, Thermodynamics on control of inclusions composition in ultraclean steels, ISIJ Int., 36(1996), No. 5, p. 528.

J.J. Wang, L.F. Zhang, T.J. Wen, Y. Ren, and W. Yang, Kinetic prediction for the composition of inclusions in the molten steel during the electroslag remelting, Metall. Mater. Trans. B, 52(2021), No. 3, p. 1521.

J. Zhang, Calculating model of mass action concentrations for the slag system MnO-SiO2, J. Univ. Sci. Technol. Beijing, 8(1986), No. 4, p. 1.

X.M. Yang, C.B. Shi, M. Zhang, G.M. Chai, and F. Wang, A thermodynamic model of sulfur distribution ratio between CaO-SiO2-MgO-FeO-MnO-Al2O3 slags and molten steel during LF refining process based on the ion and molecule coexistence theory, Metall. Mater. Trans. B, 42(2011), No. 6, p. 1150.

S.C. Duan, C. Li, X.L. Guo, H.J. Guo, J. Guo, and W.S. Yang, A thermodynamic model for calculating manganese distribution ratio between CaO-SiO2-MgO-FeO-MnO-Al2O3-TiO2-CaF2 ironmaking slags and carbon saturated hot metal based on the IMCT, Ironmaking Steelmaking, 45(2018), No. 7, p. 655.

A. Harada, N. Maruoka, H. Shibata, and S.Y. Kitamura, A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part2. condition to control inclusion composition, ISIJ Int., 53(2013), No. 12, p. 2118.

L.P. Fu, H.Z. Gu, A. Huang, Y.S. Zou, and H.W. Ni, Enhanced corrosion resistance through the introduction of fine pores: Role of nano-sized intracrystalline pores, Corros. Sci., 161(2019), art. No. 108182.

L. Fu, Y.S. Zou, A. Huang, H.Z. Gu, and H.W. Ni, Corrosion mechanism of lightweight microporous alumina-based refractory by molten steel, J. Am. Ceram. Soc., 102(2019), No. 6, p. 3705.

P.V. Danckwerts, Kinetics of the absorption of carbon dioxide in water, [in] Insights into Chemical Engineering, Elsevier, Amsterdam, 1981, p. 5.

J.H. Wei and A. Mitchell, Changes in composition during A. C.ESR—I. Theoretical development, Acta Metall. Sin., 20(1984), No. 5, p. 387.

D. Hou, Z.H. Jiang, Y.W. Dong, W. Gong, Y.L. Cao, and H.B. Cao, Effect of slag composition on the oxidation kinetics of alloying elements during electroslag remelting of stainless steel: Part-1 mass-transfer model, ISIJ Int., 57(2017), No. 8, p. 1400.

D. Hou, Z.H. Jiang, Y.W. Dong, Y. Li, W. Gong, and F.B. Liu, Mass transfer model of desulfurization in the electroslag remelting process, Metall. Mater. Trans. B, 48(2017), No. 3, p. 1885.

W.T. Lou and M.Y. Zhu, Numerical simulation of desulfurization behavior in gas-stirred systems based on computation fluid dynamics-simultaneous reaction model (CFD-SRM) coupled model, Metall. Mater. Trans. B, 45(2014), No. 5, p. 1706.

J.C. Lamont and D.S. Scott, An eddy cell model of mass transfer into the surface of a turbulent liquid, AIChE J., 16(1970), No. 4, p. 513.

Acknowledgements

This work was financially supported by the National Natural Science Foundation China (Nos. U1860206, 51725402, and 51874032), the Fundamental Research Funds for the Central Universities (Nos. FRF-TP-19-037A2Z and FRF-BD-20-04A), the S&T Program of Hebei, China (No. 20311006D), the High Steel Center (HSC) at Yanshan University, China, and the High Quality Steel Consortium (HQSC) at University of Science and Technology Beijing, China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Jj., Zhang, Lf., Cheng, G. et al. Dynamic mass variation and multiphase interaction among steel, slag, lining refractory and nonmetallic inclusions: Laboratory experiments and mathematical prediction. Int J Miner Metall Mater 28, 1298–1308 (2021). https://doi.org/10.1007/s12613-021-2304-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2304-4