Abstract

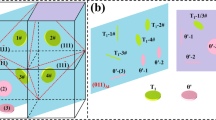

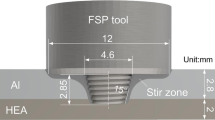

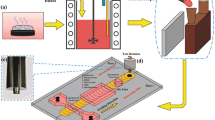

The effects of multipass friction stir processing (FSP) and Mg powder addition on the different microstructure parts, including the stir zone (SZ), heat-affected zone (HAZ), and thermomechanically affected zone (TMAZ) of Al 1050 alloy were investigated. Microstructural observations revealed that with the increase in the number of FSP passes, the grain size of the SZ decreased in the non-composite and composite samples, whereas that of the TMAZ and HAZ increased in the non-composite sample. Furthermore, the addition of Mg powder resulted in considerable grain refinement, and increasing the number of the FSP passes resulted in a more uniform distribution of Al—Mg intermetallic compounds in the in-situ composite sample. Results of the tensile test showed that the non-composite sample that underwent four passes of FSP exhibited a higher elongation percentage and a ductile fracture in comparison with those of the base metal and the composite sample. However, this sample exhibited a brittle fracture and a higher tensile strength in comparison with the base metal and the non-composite sample. The fabrication of composite samples resulted in a remarkable enhancement in hardness in comparison with the base metal and the non-composite samples that underwent FSP.

Similar content being viewed by others

References

M.M. Esfahani, H.D. Manesh, M. Esmailzadeh, and E. Roshanaei, Microstructure and wear characteristics of 1050Al/Fe surface composites by friction stir processing, Mater. Res. Express, 5(2018), No. 12, art. No. 126518.

R.S. Mishra, M.W. Mahoney, Y. Sato, and Y. Hovanski, eds., Friction Stir Welding and Processing VIII, John Wiley & Sons, Inc., Hoboken, USA, 2015.

A.N. Attia, Surface metal matrix composites, Mater. Des., 22(2001), No. 6, p. 451.

L.R. Katipelli and N.B. Dahotre, Mechanism of high temperature oxidation of laser surface engineered TiC/Al alloy ‘composite’ coating on 6061 aluminium alloy, Mater. Sci. Technol., 17(2001), No. 9, p. 1061.

B. Sattari, M. Shamanian, A. Ashrafi, M. Salehi, and F. Salimijazi, Effect of number of passes on the corrosion behavior of Fe/Al surface composites produced by plasma spraying and friction stir processing, J. Mater. Process. Technol., 250(2017), p. 35.

W.H. Peng, S.Z. Hao, J. Chen, W. Li, L.M. Zhao, and J. Deng, Surface composite microstructure and improved mechanical property of YG10X cemented carbide induced by high current pulsed electron beam irradiation, Int. J. Refract. Met. Hard Mater., 78(2019), p. 233.

K. Li, X.M. Liu, and Y. Zhao, Research status and prospect of friction stir processing technology, Coatings, 9(2019), No. 2, art. No. 129.

H.B. Michael Rajan, S. Ramabalan, I. Dinaharan, and S.J. Vijay, Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites, Mater. Des., 44(2013), p. 438.

R.A. Varin, Intermetallic-reinforced light-metal matrix in situ composites, Metall. Mater. Trans. A, 33(2002), No. 1, p. 193.

H.X. Peng, D.Z. Wang, L. Geng, C.K. Yao, and J.F. Mao, Evaluation of the microstructure of in situ reaction processed Al3Ti—Al2O3—Al composite, Scripta Mater., 37(1997), No. 2, p. 199.

S.R. Anvari, F. Karimzadeh, and M.H. Enayati, A novel route for development of Al—Cr—O surface nano-composite by friction stir processing, J. Alloys Compd., 562(2013), p. 48.

L.M. Ke, C.P. Huang, L. Xing, and K.H. Huang, Al—Ni inter-metallic composites produced in situ by friction stir processing, J. Alloys Compd., 503(2010), No. 2, p. 494.

I.S. Lee, P.W. Kao, C.P. Chang, and N.J. Ho, Formation of Al—Mo intermetallic particle-strengthened aluminum alloys by friction stir processing, Intermetallics, 35(2013), p. 9.

G. Azimi-Roeen, S.F. Kashani-Bozorg, M. Nosko, and P. Švec, Reactive mechanism and mechanical properties of in-situ hybrid nano-composites fabricated from an Al—Fe2O3 system by friction stir processing, Mater. Charact., 127(2017), p. 279.

P. Nelaturu, S. Jana, R.S. Mishra, G. Grant, and B.E. Carlson, Influence of friction stir processing on the room temperature fatigue cracking mechanisms of A356 aluminum alloy, Mater. Sci. Eng. A, 716(2018), p. 165.

L.Q. Wang, L.C. Xie, Y.T. Lü, L.C. Zhang, L.Y. Chen, Q. Meng, J. Qu, D. Zhang, and W.J. Lu, Microstructure evolution and superelastic behavior in Ti—35Nb—2Ta—3Zr alloy processed by friction stir processing, Acta Mater., 131(2017), p. 499.

D.A. Porter, K.E. Easterling, and K.E. Easterling, Phase Transformation in Metals and Alloys (Revised Reprint), CRC Press, Boca Raton, 2009.

T.C. Schulthess, P.E.A. Turchi, A. Gonis, and T.G. Nieh, Systematic study of stacking fault energies of random Al-based alloys, Acta Mater., 46(1998), No. 6, p. 2215.

T. Morishige, T. Hirata, T. Uesugi, Y. Takigawa, M. Tsujikawa, and K. Higashi, Effect of Mg content on the minimum grain size of Al—Mg alloys obtained by friction stir processing, Scripta Mater., 64(2011), No. 4, p. 355.

M.S. Soliman, The high-temperature creep behaviour of an Al—1 wt% Cu solid-solution alloy, J. Mater. Sci., 28(1993), No. 16, p. 4483.

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, W.H. Bingel, and R.A. Spurling, Properties of friction-stir-welded 7075 T651 aluminum, Metall. Mater. Trans. A, 29(1998), No. 7, p. 1955.

J.W. Martin, R.D. Doherty, and B. Cantor, Stability of Microstructure in Metallic Systems, 2nd ed., Cambridge University Press, Cambridge, 1997.

K.F. Adam, Z.D. Long, and D.P. Field, Analysis of particle-stimulated nucleation (PSN)-dominated recrystallization for hot-rolled 7050 aluminum alloy, Metall. Mater. Trans. A, 48(2017), No. 4, p. 2062.

C.S. Ramesh, R. Keshavamurthy, P.G. Koppad, and K.T. Kashyap, Role of particle stimulated nucleation in recrystallization of hot extruded Al 6061/SiCp composites, Trans. Nonferrous Met. Soc. China, 23(2013), No. 1, p. 53.

B. Verlinden, J.H. Driver, I. Samajdar, and R. Doherty, Thermo-Mechanical Processing of Metallic Materials, Elsevier, Great Britain, 2007.

S.S. Mirjavadi, M. Alipour, A.M.S. Hamouda, A. Matin, S. Kord, B.M. Afshari, and P.G. Koppad, Effect of multi-pass friction stir processing on the microstructure, mechanical and wear properties of AA5083/ZrO2 nanocomposites, J. Alloys Compd., 726(2017), p. 1262.

E. Moustafa, Effect of multi-pass friction stir processing on mechanical properties for AA2024/Al2O3 nanocomposites, Materials, 10(2017), No. 9, art. No. 1053.

T.R. McNelley, S. Swaminathan, and J.Q. Su, Recrystallization mechanisms during friction stir welding/processing of aluminum alloys, Scripta Mater., 58(2008), No. 5, p. 349.

M. Azizieh, A.H. Kokabi, and P. Abachi, Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing, Mater. Des., 32(2011), No. 4, p. 2034.

S. Tutunchilar, M. Haghpanahi, M.K. Besharati Givi, P. Asadi, and P. Bahemmat, Simulation of material flow in friction stir processing of a cast Al—Si alloy, Mater. Des., 40(2012), p. 415.

G. Dowson, Powder Metallurgy the Process and Its Products, Adam Hilger, Bristol, 1990, p. 167.

Q. Zhang, B.L. Xiao, W.G. Wang, and Z.Y. Ma, Reactive mechanism and mechanical properties of in situ composites fabricated from an Al-TiO2 system by friction stir processing, Acta Mater., 60(2012), No. 20, p. 7090.

G.E. Dieter, Mechanical Metallurgy, McGraw-Hill, New York, 1986.

M. Hajizamani and M. Alizadeh, Modification of microstructure and mechanical properties of Al-Zn-Mg/3 wt.% Al2O3 composite through semi-solid thermomechanical processing using variable loads, Int. J. Mater. Res., 108(2017), No. 10, p. 840.

F.J. Humphreys and M. Hatherly, Recrystallization textures [in] Recrystallization and Related Annealing Phenomena, Elsevier, Amsterdam, 1995, p. 327.

Y.H. Zhao, X.Z. Liao, S. Cheng, E. Ma, and Y.T. Zhu, Simultaneously increasing the ductility and strength of nanostructured alloys, Adv. Mater., 18(2006), No. 17, p. 2280.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Rastabi, S.A., Mosallaee, M. Effects of multipass friction stir processing and Mg addition on the microstructure and tensile properties of Al 1050 alloys. Int J Miner Metall Mater 29, 97–107 (2022). https://doi.org/10.1007/s12613-020-2074-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2074-4