Abstract

A biodegradable poly-lactic acid (PLA) microneedle array composed of needles with a maximum length of 3 mm and an aspect ratio of up to approximately 18 was fabricated by drawing lithography. In the proposed fabrication method, the melted polymer is stretched twice. The approximate length is set in the first stretch, and the tip is sharpened in the second stretch. In the first stretch, by changing the thickness of the PLA sheet, PLA pillars with various lengths are fabricated. By defining the initial length of the needle, it is possible to set a wide range of aspect ratios and lengths. In the second stretch, it is possible to control the final aspect ratio and length of the needle, as well as the shape of its tip by changing the temperature and stretch speed of the PLA pillars. Finally, it was confirmed that the needle can pierce the surface of artificial skin and porcine skin.

Similar content being viewed by others

References

Singh, R., Singh, S., & Lillard, J. W. (2008). Past, present, and future technology for oral delivery of therapeutic proteins. Journal of Pharmaceutical Sciences, 97, 2497–2523.

Barry, B. W. (2004). Breaching the skin’s barrier to drugs. Nature Biotechnology, 22, 165–167.

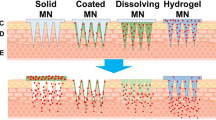

Kim, Y. C., Park, J. H., & Prausnitz, M. R. (2012). Microneedles for drug and vaccine delivery. Advanced Drug Delivery Reviews, 64, 1547–1568.

Larraneta, E., Lutton, R. E. M., Woolfson, A. D., & Donnelly, R. F. (2016). Microneedle arrays as transdermal and intradermal drug delivery systems: materials science, manufacture and commercial development. Materials Science and Engineering R, 104, 1–32.

Martanto, W., Davis, S. P., Holiday, N. R., Wang, J., Gill, H. S., & Prausnitz, M. R. (2004). Transdermal delivery of insulin using microneedles in vivo. Pharmaceutical Research, 21(6), 947–952.

Donnelly, R. F., Singh, T. R. R., Tunney, M. M., Morrow, D. I. J., McCarron, P. A., Mahony, C. O., et al. (2009). Microneedle arrays allow lower microbial penetration than hypodermic needles in vitro. Pharmaceutical Research, 26(11), 2513–2522.

Roxhed, N., Gasser, T. C., Griss, P., Holzapfel, G. A., & Stemme, G. (2007). Penetration-enhanced ultrasharp microneedles and prediction on skin interaction for efficient transdermal drug delivery. Journal of Microelectromechanical Systems, 16(6), 1429–1440.

Griss, P., Enoksson, P., Tolvanen-Laakso, H. K., Merilainen, P., Ollmar, S., & Stemme, G. (2001). Micromachined electrodes for biopotential measurements. Journal of Microelectromechanical System, 10(1), 10–16.

Griss, P., & Stemme, G. (2003). Side-opened out-of-plane microneedles for microfluidic transdermal liquid transfer. Journal of Microelectromechanical System, 12(3), 296–301.

Bystrova, S., & Luttge, R. (2011). Micromolding for ceramic microneedle arrays. Microelectric Engineering, 88, 1681–1684.

Hiraishi, Y., Hirobe, S., Iioka, H., Quan, Y. S., Kamiyama, F., Asada, H., et al. (2013). Development of a novel therapeutic approach using a retinoic acid-loaded microneedle patch for seborrheic keratosis treatment and safety study in humans. Journal of Controlled Release, 171, 93–103.

Park, J. H., Davis, S., Yoon, Y. K., Prausnitz, M. R., and Allen, M. G. (2003). Micromachined biodegradable microstructures. The 16th Annual International Conference on Micro Electro Mechanical Systems, pp 371–374.

Yagyu, H., Hayashi, S., & Tabata, O. (2006). Fabrication of plastic micro tip array using laser micromachining of nanoparticles dispersed polymer and micromolding. IEEJ Transactions on Sensors and Micromachines, 126(1), 7–13.

Miyano, T., Tobinaga, Y., Kanno, T., Matsuzaki, Y., Takeda, H., Wakui, M., et al. (2005). Sugar micro needles as transdermic drug delivery system. Biomedical Microdevices, 7(3), 185–188.

Park, J. H., Choi, S. O., Seo, S., Choy, Y. B., & Prausnitz, M. R. (2010). A microneedle roller for transdermal drug delivery. European Journal of Pharmaceutics and Biopharmaceutics, 76, 282–289.

Cha, K. J., Kim, T., Park, S. J., & Kim, D. S. (2014). Simple and cost-effective fabrication of solid biodegradable polymer microneedle arrays with adjustable aspect ratio for transdermal drug delivery using acupuncture microneedles. Journal of Micromechanics and Microengineering, 24, 1–8.

Lee, S. G., Jeong, J. H., Lee, K. M., Jeong, K. H., Yang, H., Kim, M., et al. (2014). Nanostructured lipid carrier-loaded hyaluronic acid microneedles for controlled dermal delivery of a lipophilic molecule. International Journal of Nanomedicine, 9, 289–299.

Lee, K., Park, S. H., Lee, J. Y., Ryu, S., Joo, C., & Ryu, W. H. (2019). Three-step thermal drawing for rapid prototyping of highly customizable microneedles for vascular tissue insertion. Pharmaceutics, 11(100), 11030100.

Lee, K., Lee, C. Y., & Jung, H. (2011). Dissolving microneedles for transdermal drug administration prepared by stepwise controlled drawing of maltose. Biomaterials, 32, 3134–3140.

Lee, K., Kim, J. D., Lee, C. Y., Her, S., & Jung, H. (2011). A high-capacity, hybrid electro-microneedle for in-situ cutaneous gene transfer. Biomaterials, 32, 7705–7710.

Kim, J. D., Kim, M., Yang, H., Lee, K., & Jung, H. (2013). Droplet-born air blowing: novel dissolving microneedle fabrication. Journal of Controlled Release, 170, 430–436.

Yang, H., Kim, S., Kang, G., Lahiji, S. F., Jang, M., Kim, Y. M., et al. (2017). Centrifugal lithography: self-shaping of polymer microstructures encapsulating biopharmaceutics by centrifuging polymer drops. Advanced Healthcare Materials, 6, 1700326.

Lou, C. W., Yao, C. H., Chen, Y. S., Hsieh, T. C., Lin, J. H., & Hsing, W. H. (2008). Manufacturing and properties of PLA absorbable surgical suture. Textile Research Journal, 78(11), 958–965.

Perego, G., Cella, G. D., & Bastioli, C. (1996). Effect of molecular weight and crystallinity on poly (lactic acid) mechanical properties. Journal of Applied Polymer Science, 59, 37–43.

Yao, M., McKinley, G. H., & Debbaut, B. (1998). Extensional deformation, stress relaxation and necking failure of viscoelastic filaments. Journal of Non-Newtonian Fluid Mechanics, 79, 469–501.

Suzuki, M., Takahashi, T., & Aoyagi, S. (2018). 3D laser lithographic fabrication of hollow microneedle mimicking mosquitos and its characterization. International Journal of Nanotechnology, 15, 157–173.

Lee, K., & Jung, H. (2012). Drawing lithography for microneedles: a review of fundamentals and biomedical application. Biomaterials, 33, 7309–7326.

Kolte, M. I., & Rasmussen, H. K. (1997). Transient filament stretching rheometer. Rheologica Acta, 36, 285–302.

Acknowledgements

This work was supported by KAKENHI (18H01415) from JSPS (Japanese Society for the Promotion of Science). This work was supported in part by a Strategic Research Foundation at Private Universities “Creation of 3D nano-micro structures and its application to biomimetics and medicine” from MEXT (Ministry of Education, Culture, Sports, Science, and Technology, Japan), 2015–2019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Terashima, S., Tatsukawa, C., Suzuki, M. et al. Twice Stretched Fabrication of Polylactic Acid Microneedle Arrays Using Drawing Lithography. Int. J. Precis. Eng. Manuf. 21, 1933–1942 (2020). https://doi.org/10.1007/s12541-020-00380-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00380-2