Abstract

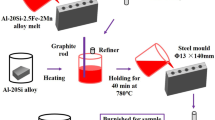

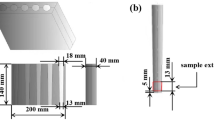

Effect of manganese (Mn) addition (0.0, 1.0, 2.0 and 3 wt%) on the microstructural morphology, hardness, tensile properties and fracture behaviour of the gravity cast eutectic Al–12.6Si alloy has been studied through XRD analysis, chemical analysis, optical metallography, FESEM analysis, energy dispersive spectroscopy analysis, hardness test, tensile test and quantitative phase analysis. As-cast Al–12.6Si–0.0Mn alloy has a non-uniformly distributed coarser and irregular shape primary and eutectic silicon particles inside the α-Al phase, and both the Si phase have very sharp corners. Whereas, the 1 wt% Mn added alloy has uniformly distributed fine eutectic and primary Si particles with blunt corners. Further, the addition of 1.0 wt% Mn forms very few (0.26 vol %) irregular shape Al15(MnFe)3Si2 intermetallic phase within the α-Al phase and eutectic Si phase. But, 2.0 wt% and 3 wt% Mn added alloy has an irregular shape coarse plate-like Al15(MnFe)3Si2 intermetallic phase besides the primary and eutectic Si phase. The bulk hardness of the Al–12.6Si alloy is increased with an increase in Mn concentration as the harder Al15(MnFe)3Si2 intermetallic phase forms and both the Si phase morphology modify. The microhardness of the constituent phases also varies with the change in Mn concentration in the alloy. The Mn addition improved the ultimate tensile strength, yield strength, and elongation (%) of the alloy. However, fractographs reveal that the brittle mode of fracture has been increased due to the presence of a higher volume of brittle Al15(MnFe)3Si2 intermetallic in 2.0 and 3.0% Mn alloy. On the other hand, the amount of brittle and cleavage fracture of Si particles decreased, and ductile fracture with dimples formation increased in 1.0 wt%Mn added alloy.

Graphic Abstract

Similar content being viewed by others

References

P. Biswas, M.K. Mondal, D. Mandal, Effect of Mg2Si concentration on the dry sliding wear behavior of Al–Mg2Si composite. J. Tribol T ASME 141, 081601 (2019)

C.R. Barbosa, G.H. Machado, H.M. Azevedo, F.S. Rocha, J.C. Filho, A.A. Pereira, O.L. Rocha, Tailoring of processing parameters, dendritic microstructure, Si/intermetallic particles and microhardness in as-cast and heat-treated samples of Al7Si0.3Mg alloy. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00334-y

F.A. Souza, I.A. Magno, M.O. Costa, A.S. Barros, J.M. Nascimento, D.B. Carvalho, O.L. Rocha, Unsteady-state Horizontal solidifcation of an Al–Si–Cu–Fe alloy: relationship between thermal parameters and microstructure with mechanical properties/fracture feature. Met. Mater. Int. 25, 18–33 (2019)

J.-Y. Heo, J.-H. Gwon, J.-K. Park, K.-A. Lee, Efects of heat treatment on the microstructures and high temperature mechanical properties of hypereutectic Al–14Si–Cu–Mg alloy manufactured by liquid phase sintering process. Met. Mater. Int. 24, 586–596 (2018)

P. Kumar, M.F. Wani, Effect of load on the tribological properties of hypereutectic Al–Si alloy under boundary lubrication conditions. Mater. Res. Express 4, 116519 (2017)

P. Jia, J. Zhang, X. Hu, X. Teng, M. Zuo, Z. Gao, C. Yang, D. Zhao, Grain refining effects of the melt thermal-rate treatment and Al–Ti–B–Y refiner in as-cast Al–9Si–0.5Mg alloy. Mater. Res. Express 5, 066520 (2018)

C. Li, Y. Pan, T. Lu, L. Jing, J. Pi, Effects of Ti and La additions on the microstructures and mechanical properties of B-refined and Sr-modified Al–11Si alloys. Met. Mater. Int. 24, 1133–1142 (2018)

S.-W. Lee, M.-S. Kim, High temperature deformation behavior of spray-formed and subsequently extruded Al–25Si based alloy. Met. Mater. Int. 22, 579–584 (2016)

K.-H. Kim, M.-S. Kim, High temperature tensile properties of hypereutectic Al–25Si based alloy. Met. Mater. Int. 24, 136–141 (2018)

P. Biswas, R. Bhandari, M.K. Mondal, D. Mandal, Effect of microstructural morphology on microscale deformation behavior of Al–4.5Cu–2Mg alloy. Arch. Metall. Mater. 63, 1575–1586 (2018)

R. Bhandari, P. Biswas, M.K. Mondal, D. Mandal, Finite element analysis of stress-strain localization and distribution in Al–4.5Cu–2Mg alloy. Trans. Nonferrous Met. Soc. China 28, 1200–1215 (2018)

P. Biswas, D. Mandal, M.K. Mondal, Micromechanical response of Al–Mg2Si composites using approximated representative volume elements (RVEs) model. Mater. Res. Express 6, 1165c6 (2019)

S.A. Kori, B.S. Murty, M. Chakraborty, Development of an efficient grain refiner for Al–7% Si alloy. Mater. Sci. Eng. A 280, 58–61 (2000)

K. Nan, C. Pierre, C. Chaoyue, W. Yan, L. Hanlin, C. Christian, Microstructure and wear behavior of in situ hypereutectic Al–high Si alloys produced by selective laser melting. Mater. Des. 99, 120–126 (2016)

Q. Li, T. Xia, Y. Lan, W. Zhao, L. Fan, P. Li, Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al–20% Si alloy. J Alloys Compd. 562, 25–32 (2013)

S. Zhang, J. Leng, Z. Wang, Q. Wang, Y. Shao, X. Teng, Investigation on the modification behavior of A356.2 alloy with Yb–La composite modifier. Mater. Res. Express 5, 016520 (2018)

P. Biswas, K.D. Prasadu, M.K. Mondal, Effect of Bi addition on microstructure and mechanical properties of hypereutectic Al–17.6Si alloy. Mater. Res. Express 6, 1165b9 (2019)

O. Fakhraei, M. Emamy, H. Farhangi, The effect of Al–5Ti–1B grain refiner on the structure and tensile properties of Al–20%Mg alloy. Mater. Sci. Eng. A 560, 148–153 (2013)

Y. Chen, Y. Pan, T. Lu, S. Tao, J. Wu, Effects of combinative addition of lanthanum and boron on grain refinement of Al–Si casting alloys. Mater. Des. 64, 423–426 (2014)

Y. Birol, Effect of silicon content in grain refining hypoeutectic Al–Si foundry alloys with boron and titanium additions. Mater. Sci. Technol. 28, 385–389 (2012)

J.E. Gruzleski, B.M. Closset, The Treatment of Liquid Aluminium–Silicon Alloys, 1st edn. (American Foundrymen’s Society, Des Plaines, 1990), p. 34

P. Srirangam, M.J. Kramer, S. Shankar, Effect of strontium on liquid structure of Al–Si hypoeutectic alloys using high-energy X-ray diffraction. Acta Mater. 59, 503–513 (2011)

M.G. Mahmoud, E.M. Elgallad, M.F. Ibrahim, F.H. Samuel, Effect of rare earth metals on porosity formation in A 356 alloy. Int. J. Metalcast. 12, 251–265 (2018)

R. Lazarova, N. Bojanova, R. Dimitrova, I. Panov, V. Manolov, Influence of nanoparticles introducing in the melt of aluminum alloys on castings microstructure and properties. Int. J. Metalcast. 10, 466–476 (2016)

L. Li, Z. Zhao, Y. Zuo, Q. Zhu, J. Cui, Effect of a high magnetic field on the morphological and crystallographic features of primary Al6Mn phase formed during solidification process. J. Mater. Res. 28, 1567–1573 (2013)

S.G. Shabestari, The effect of iron and manganese on the formation of intermetallic compounds in aluminium–silicon alloys. Mater. Sci. Eng. A 383, 289–298 (2004)

J.Y. Hwang, H.W. Doty, M.J. Kaufman, The effects of Mn additions on the microstructure and mechanical properties of Al–Si–Cu casting alloys. Mater. Sci. Eng. A 488, 496–504 (2008)

P. Biswas, S. Patra, M.K. Mondal, Effects of Mn addition on microstructure and hardness of Al–12.6Si alloy. IOP Conf. Ser. Mater. Sci. Eng. 338, 012043 (2018)

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, M.-A. Van Ende, FactSage thermochemical software and databases 2010–2016. Calphad 54, 35–53 (2016)

M. Gupta, S. Ling, Microstructure and mechanical properties of hypo/hyper-eutectic Al–Si alloys synthesized using a near-net shape forming technique. J. Alloys Compd. 287, 284–294 (1999)

Q.D. Qin, Y.G. Zhao, C. Liu, P.J. Cong, W. Zhou, Strontium modification and formation of cubic primary Mg2Si crystals in Mg2Si/Al composite. J. Alloys Compd. 454, 142–146 (2007)

S. Lu, A. Hellawell, The mechanism of silicon modification in aluminum-silicon alloys: impurity induced twinning. Meta. Trans. A 18, 1721–1733 (1987)

Z. Hu, Z. Dong, Z. Yin, H. Yan, J. Tian, H. Xie, Solidification behavior, microstructure and silicon twinning of Al–10Si alloys with ytterbium addition. J Rare Earth 36, 662–668 (2018)

R. Goswami, G. Spanos, P.S. Paoa, R.L. Holtz, Precipitation behavior of the phase in Al-5083. Mater. Sci. Eng. A 527, 1089–1095 (2010)

M.R. Ghorbania, M. Emamy, R. Khorshidi, J. Rasizadehghani, A.R. Emami, Effect of Mn addition on the microstructure and tensile properties of Al–15%Mg2Si composite. Mater. Sci. Eng. A 550, 191–198 (2012)

R. Arrabal, B. Mingo, A. Pardo, M. Mohedano, E. Matykina, I. Rodríguez, Pitting corrosion of rheocast A356 aluminium alloy in 3.5 wt% NaCl solution. Corros. Sci. 73, 342–355 (2013)

H.Y. Yan, W. Qun, S.M. Chang, G.U. Ping, A first-principle calculation of structural, mechanical and electronic properties of titanium borides. Trans. Nonferrous Met. Soc. China 21, 1627–1633 (2011)

P. Biswas, M.K. Mondal, H. Roy, D. Mandal, Microstructural evolution and hardness property of in situ Al–Mg2Si composites using one-step gravity casting method. Can. Metall. Q. 56, 340–348 (2017)

H.C. Yu, H.Y. Wang, L. Chen, M. Zha, C. Wang, C. Li, Q.C. Jiang, Spheroidization of primary Mg2Si in Al-20Mg2Si–4.5Cu alloy modified with Ca and Sb during T6 heat treatment process. Mater. Sci. Eng. A 685, 31–38 (2017)

L.F. Mondolfo, Aluminium Alloys: Structure and Properties (Butterworth, London, 1976), p. 324

L. Alyaldin, M.H. Abdelaziz, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Effect of Ni and Mn additions on the ambient and high-temperature performance of Zr-containing Al–Si–Cu–Mg-based alloys: role of precipitation hardening. Int. J. Metalcast. 12, 825–838 (2018)

L.K. Walford, The structure of the intermetallic phase FeAl6. Acta Cryst. 18, 287–291 (1965)

E.R. Wang, X.D. Hui, S.S. Wang, Y.F. Zhao, G.L. Chen, Improved mechanical properties in cast Al–Si alloys by combined alloying of Fe and Cu. Mater. Sci. Eng. A 527, 7878–7884 (2010)

P. Biswas, A. Biswas, R. Bhandari, M.K. Mondal, Microstructure, mechanical properties and fracture behavior of in situ Al–5Mg–Al4Sr composites. Mater. Today Comm. 15, 190–198 (2018)

Acknowledgements

Authors are very thankful to Mr. S C. Das and Mr. M. K. Das of the National Institute of Technology Durgapur, India, for their support in several phases of this investigation. Authors are also like to thank NIT, Durgapur RIG # 2 project for financial support, and the Director of National Institute of Technology Durgapur, India, for his continuous encouragement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Biswas, P., Patra, S., Roy, H. et al. Effect of Mn Addition on the Mechanical Properties of Al–12.6Si Alloy: Role of Al15(MnFe)3Si2 Intermetallic and Microstructure Modification. Met. Mater. Int. 27, 1713–1727 (2021). https://doi.org/10.1007/s12540-019-00535-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00535-5