Abstract

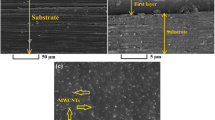

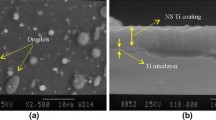

The influence of nano-silica doping on the growth behavior and corrosion resistance of γ-APS silane films fabricated by electrochemical-assisted deposition was systematically investigated by reflection absorption infrared spectroscopy, electrochemical impedance spectroscopy, atomic force microscopy, scanning electron microscopy, energy-dispersive X-ray spectrometry, contact angle test and neutral salt spray test. Density functional theory calculation was also applied to elaborate the adsorption behavior of γ-APS on low carbon steel surfaces. And meanwhile, the changes of surface coverage and dissolved oxygen reduction in the cathode surface over time were intensively analyzed according to the I–t curve during electrodeposition process. The experimental results revealed that the impedance values of the composite films firstly increased and then decreased with increasing nano-silica concentration, and there was a critical doping concentration about 0.4 g·L−1, under which the obtained γ-APS silane composite films presented high compactness and protective properties. Other results were highly consistent with the electrochemical results. Moreover, the hydroxyl-rich nano-silica was also involved in the chemical reactions that occurred on the metal surfaces, and the influence mechanism was proposed.

Similar content being viewed by others

References

Dalmoro, V, Azambuja, DS, Alemán, C, Armelin, E, “Hybrid Organophosphonic-silane Coating for Corrosion Protection of Magnesium Alloy AZ91: The Influence of Acid and Alkali Pre-treatments.” Surf. Coat. Technol., 357 728–739. https://doi.org/10.1016/j.surfcoat.2018.10.013 (2019)

Zhang, G, Tang, A, Wu, L, Zhang, Z, et al. “In-situ Grown Super- or Hydrophobic Mg-Al Layered Double Hydroxides Films on the Anodized Magnesium Alloy to Improve Corrosion Properties.” Surf. Coat. Technol., 366 238–247. https://doi.org/10.1016/j.surfcoat.2019.03.016 (2019)

Vinothkumar, K, Rajkumar, G, Sethuraman, MG, “Enhancement of Protection of Copper Through Electropolymerised Poly-2-amino-1, 3, 4-Thiadiazole and Its Composite Films.” Mater. Chem. Phys., 259 123987–124000. https://doi.org/10.1016/j.matchemphys.2020.123987 (2021)

Merisalu, M, Aarik, L, Kozlova, J, “Effective Corrosion Protection of Aluminum Alloy AA2024-T3 with Novel Thin Nanostructured Oxide Coating.” Surf. Coat. Technol., 411 126993–127005. https://doi.org/10.1016/j.surfcoat.2021.126993 (2021)

Dun, YC, Zhao, XH, Tang, YM, Dino, S, et al. “Microstructure and Corrosion Resistance of a Fluorosilane Modified Silane-Graphene Film on 2024 Aluminum Alloy.” Appl. Surf. Sci., 437 152–160. https://doi.org/10.1016/j.apsusc.2017.12.109 (2018)

BinSabt, MH, Galal, A, Alkharafi, FM, Abditon, M, “Improving Corrosion Protection of Al97Mg3 Alloy in Neutral Sodium Chloride Solution by 1, 2-Bis(triethoxysilyl)ethane Coating.” Appl. Surf. Sci., 465 143–153. https://doi.org/10.1016/j.apsusc.2018.09.111 (2019)

Cao, ZF, Wang, J, Qiu, P, Yang, F, et al. “Hydrophobic Coatings for Improving Corrosion Resistance of Manganese Substrate.” Surf. Coat. Technol., 347 235–244. https://doi.org/10.1016/j.surfcoat.2018.04.075 (2018)

Mercier-Bion, F, Li, JY, Lotz, H, Tortech, L, et al. “Electrical Properties of Iron Corrosion Layers in Anoxic Environments at the Nanometer Scale.” Corros. Sci., 137 98–110. https://doi.org/10.1016/j.corsci.2018.03.028 (2018)

Yang, LX, Liu, MX, Lei, XL, Zhang, YX, “Study on the Adsorption Behavior of γ-GPS on Low Carbon Steel Surfaces Using RA-IR, EIS and AFM.” Appl. Surf. Sci., 257 9895–9903. https://doi.org/10.1016/j.apsusc.2011.06.102 (2011)

Indira, K, Ezhil Vizhi, M, Kathirvel, B, et al. “Examining the Uniformity of the Superhydrophobic Coating On Steel Substrates Using Kelvin Probe Force Microscope.” Prog. Org. Coat., 150 105973–105978. https://doi.org/10.1016/j.porgcoat.2020.105973 (2021)

Hu, JM, Liu, L, Zhang, JQ, Cao, CN, “Electrodeposition of Silane Films on Aluminum Alloys for Corrosion.” Prog. Org. Coat., 58 265–271. https://doi.org/10.1016/j.porgcoat.2006.11.008 (2007)

Wang, C, Jiao, GS, Peng, L, Zhu, BL, et al. “Influences of Surface Modification of Nano-silica by Silane Coupling Agents on the Thermal and Frictional Properties of Cyanate Ester Resin.” Results Phys., 9 886–896. https://doi.org/10.1016/j.rinp.2018.03.056 (2018)

Grard, A, Belec, L, Perrin, FX, “Effect of Surface Morphology on the Adhesion of Silicone Elastomers on AA6061 Aluminum Alloy.” Int. J. Adhes. Adhes., 102 102656–102572. https://doi.org/10.1016/j.ijadhadh.2020.102656 (2020)

Van Ooij, WJ, Zhu, DQ, Stacy, M, Seth, A, et al. “Corrosion Protection Properties of Organofunctional Silanes: An Overview." Tsinghua Sci. Technol., 10 639–664. https://doi.org/10.1016/S1007-0214(05)70134-6 (2005)

Yang, LX, Feng, J, Zhang, WG, Qu, JE, “Film Forming Kinetics and Reaction Mechanism of γ-Glycidoxypropyltrimethoxysilane on Low Carbon Steel Surfaces.” Appl. Surf. Sci., 256 6787–6794. https://doi.org/10.1016/j.apsusc.2010.04.090 (2010)

Yang, LX, Feng, J, Zhang, WG, Qu, JE, “Experimental and Computational Study on Hydrolysis and Condensation Kinetics of γ-Glycidoxypropyltrimethoxysilane (γ-GPS).” Appl. Surf. Sci., 257 990–996. https://doi.org/10.1016/j.apsusc.2010.07.102 (2010)

Najibzad, AS, Amini, R, Rostami, M, et al. “Active Corrosion Performance of Magnesium by Silane Coatings Reinforced with Polyaniline/praseodymium.” Prog. Org. Coat., 140 105504–105515. https://doi.org/10.1016/j.porgcoat.2019.105504 (2020)

Keshmiri, N, Mohseni, M, Yahyaei, H, “Adhesion Study of Biocompatible Polyhedral Oligomeric Silsesquioxane-Poly(carbonate-urea) Urethane Coating on Stainless Steel 316L in the Presence of an Amino-silane Primer.” Thin Solid Films, 735 138895–138903. https://doi.org/10.1016/j.tsf.2021.138895 (2021)

Zhu, DQ, van Ooij, WJ, “Corrosion Protection of AA 2024–T3 by Bis-[3-(triethoxysilyl)propyl]tetrasulfide in Sodium Chloride Solution. Part 2: Mechanism for Corrosion Protection.” Corros. Sci., 45 2177–2197. https://doi.org/10.1016/S0010-938X(03)00061-1 (2003)

Child, TF, Van Ooij, WJ, “Application of Silane Technology to Prevent Corrosion of Metals and Improve Paint Adhesion.” Met. Fin., 77 64–70. https://doi.org/10.1080/00202967.1999.11871249 (1999)

Montemor, MF, Cabral, AM, Zheludkevich, ML, Ferreira, MGS, “The Corrosion Resistance of Hot Dip Galvanized Steel Pretreated with Bis-functional Silanes Modified with Microsilica.” Surf. Coat. Technol., 9 2875–2885. https://doi.org/10.1016/j.surfcoat.2004.11.012 (2006)

Montemor, MF, Simões, AM, Ferreira, MGS, Williams, B, et al. “The Corrosion Performance of Organosilane Based Pre-treatments for Coatings on Galvanised Steel.” Prog. Org. Coat., 38 17–26. https://doi.org/10.1016/S0300-9440(99)00080-6 (2000)

Van Ooij, WJ, Zhu, DQ, Prasad, G, Jayaseelan, S, Teredesai, N, et al. “Silane Based Chromate Replacements for Corrosion Control, Paint Adhesion, and Rubber Bonding.” Surf. Eng., 16 386–396. https://doi.org/10.1179/026708400101517369 (2000)

Xiong, S, Zhao, Y, Wang, Y, et al. “Enhanced Interfacial Properties of Carbon Fiber/Epoxy Composites by Coating Carbon Nanotubes onto Carbon Fiber Surface by One-Step Dipping Method.” Appl. Surf. Sci., 546 149135–149145. https://doi.org/10.1016/j.apsusc.2021.149135 (2021)

Woo, H, Reucroft, PJ, Jacob, RJ, “Electrodeposition of Organofunctional Silanes and Its Influence on Structural Adhesive Bonding.” J. Adhes. Sci. Technol., 7 681–697. https://doi.org/10.1163/156856193X00367 (1993)

Peng, LJ, Chen, SH, Feng, YN, Li, TY, “Study on the BTSPS Silane Film Prepared on the Surface of the 2A12 Aluminum Alloy.” Adv. Mater. Res., 936 1071–1076. https://doi.org/10.4028/www.scientific.net/AMR.936.1071 (2014)

Okumoto, S, Fujita, N, Yamabe, S, “Theoretical Study of Hydrolysis and Condensation of Silicon Alkoxides.” J. Chem. Phys. A., 102 3991–3998. https://doi.org/10.1021/jp980705b (1998)

Yang, LX, Zhang, WG, Gu, T, Feng, J, “Influence of Acetic Acid on Dynamic Behavior of Hydrolazation and Film Forming of Organosilane.” J. Wuhan Univ. Technol., 24 546–551. https://doi.org/10.1007/s11595-009-4546-2 (2009)

Herlem, G, Segut, O, Antoniou, A, “Electrodeposition and Characterization of Silane Thin Films from 3-(Aminopropyl)triethoxysilane.” Surf. Coat. Technol., 202 1437–1442. https://doi.org/10.1016/j.surfcoat.2007.06.038 (2008)

Liu, L, Hu, JM, Zhang, JQ, Cao, CN, “Improving the Formation and Protective Properties of Silane Films by the Combined Use of Electrodeposition and Nanoparticles Incorporation.” Electrochim. Acta., 52 538–545. https://doi.org/10.1016/j.electacta.2006.05.034 (2006)

Wu, LK, Liu, L, Li, J, Hu, JM, et al. “Electrodeposition of Cerium(III)-modified Bis-[triethoxysilypropyl]tetra-sulphide Films on AA2024-T3 (Aluminum Alloy) for Corrosion Protection.” Surf. Coat. Technol., 204 3920–3926. https://doi.org/10.1016/j.surfcoat.2010.05.027 (2010)

Li, M, Yang, YQ, Liu, L, Hu, JM, et al. “Electro-assisted Preparation of Dodecyltrimethoxysilane/TiO2 Composite Films for Corrosion Protection of AA2024-T3 (Aluminum Alloy).” Electrochim. Acta., 55 3008–3014. https://doi.org/10.1016/j.electacta.2009.12.081 (2010)

Sheffer, M, Groysman, A, Mandler, D, “Electrodeposition of Sol-Gel Films on Al for Corrosion Protection.” Corros. Sci., 45 2893–2904. https://doi.org/10.1016/S0010-938X(03)00106-9 (2003)

Gandhi, JS, Van Ooij, WJ, “Improved Corrosion Protection of Aluminum Alloys by Electrodeposited Silanes.” J. Mater. Eng. Perform., 13 475–480. https://doi.org/10.1361/10599490420016 (2004)

Liu, YH, Xu, JB, Zhang, JT, Hu, JM, “Electrodeposited Silica Film Interlayer for Active Corrosion Protection.” Corros. Sci., 120 61–74. https://doi.org/10.1016/j.corsci.2017.01.017 (2017)

Shacham, R, Avnir, D, Mandler, D, “Electrodeposition of Methylated Sol-Gel Films on Conducting Surfaces.” Adv. Mater., 11 384–388. https://doi.org/10.1002/(SICI)1521-4095(199903)11:53.0.CO;2-M (1999)

Hu, JM, Liu, L, Zhang, JQ, Cao, CN, “Effects of Electrodeposition Potential on the Corrosion Properties of bis-1,2-[triethoxysilyl] Ethane Films on Aluminum Alloy.” Electrochim. Acta., 51 3944–3949. https://doi.org/10.1016/j.electacta.2005.11.008 (2006)

Liu, YH, Jin, XH, Hu, JM, “Electrodeposited Silica Films Post-treated with Organosilane Coupling Agent as the Pretreatment Layers of Organic Coating System.” Corros. Sci., 106 127–136. https://doi.org/10.1016/j.corsci.2016.01.032 (2016)

Mrad, M, Dhouibi, L, Montemor, MF, “Elaboration of γ-Glycidoxypropyltrimethoxysilane Coating on AA2024-T3 Aluminum Alloy: Influence of Synthesis Route on Physicochemical and Anticorrosion Properties.” Prog. Org. Coat., 121 1–12. https://doi.org/10.1016/j.porgcoat.2018.04.005 (2018)

Córdoba, LC, Montemor, MF, Coradin, T, “Silane/TiO2 Coating to Control the Corrosion Rate of Magnesium Alloys in Simulated Body Fluid.” Corros. Sci., 104 152–161. https://doi.org/10.1016/j.corsci.2015.12.006 (2016)

Tang, YJ, Tang, C, Hu, D, Gui, YG, “Effect of Aminosilane Coupling Agents with Different Chain Lengths on Thermo-Mechanical Properties of Cross-Linked Epoxy Resin.” Nanomaterials, 8 951–963. https://doi.org/10.3390/nano8110951 (2018)

Pinc, W, Maddela, S, O’Keefe, M, Fahrenholtz, W, “Formation of Subsurface Crevices in Aluminum Alloy 2024-T3 During Deposition of Cerium-Based Conversion Coatings.” Surf. Coat. Technol., 204 4095–4100. https://doi.org/10.1016/j.surfcoat.2010.05.039 (2010)

Zheng, J, Zhang, X, Cao, J, et al. “Behavior of Epoxy Resin Filled with Nano-SiO2 Treated with a Eugenol Epoxy Silane.” J. Appl. Polym. Sci., 138 50138–50148. https://doi.org/10.1002/app.50138 (2021)

de Frutos, A, Arenas, MA, Liu, Y, Skeldon, P, et al. “Influence of Pre-treatments in Cerium Conversion Treatment of AA2024-T3 and 7075–T6 Alloys.” Surf. Coat. Technol., 202 3797–3807. https://doi.org/10.1016/j.surfcoat.2008.01.027 (2008)

Xiao, W, Man, RL, Miao, C, Peng, TL, “Study on Corrosion Resistance of the BTESPT Silane Cooperating with Rare Earth Cerium on the Surface of Aluminum-Tube.” J. Rare Earths, 28 117–122. https://doi.org/10.1016/S1002-0721(09)60063-6 (2010)

Li, CC, Lai, TY, Fang, TH, “Corrosion Resistant Coatings Based on Zinc Nanoparticles, Epoxy and Silicone Resins.” J. Nanosci. Nanotechnol., 20 6389–6395. https://doi.org/10.1166/jnn.2020.18709 (2020)

Sowntharya, L, Gundakaram, RC, Soma Raju, KRC, Subasri, R, “Effect of Addition of Surface Modified Nanosilica into Silica-Zirconia Hybrid Sol–Gel Matrix.” Ceram. Int., 39 4245–4252. https://doi.org/10.1016/j.ceramint.2012.10.276 (2013)

Wang, J, Wu, LK, Zhou, JH, Hu, JM, et al. “Construction of a Novel Painting System Using Electrodeposited SiO2 Film as the Pretreatment Layer.” Corros. Sci., 68 57–65. https://doi.org/10.1016/j.corsci.2012.10.033 (2013)

Zand, RZ, Verbeken, K, Flexer, V, Adriaens, A, “Effects of Ceria Nanoparticle Concentrations on the Morphology and Corrosion Resistance of Ceriumesilane Hybrid Coatings on Electrogalvanized Steel Substrates.” Mater. Chem. Phys., 145 450–460. https://doi.org/10.1016/j.matchemphys.2014.02.035 (2014)

Chen, CD, Dong, SG, Hou, RQ, Hu, J, et al. “Insight into the Anti-Corrosion Performance of Electrodeposited Silane/Nano-CeO2 Film on Carbon Steel.” Surf. Coat. Technol., 326 183–191. https://doi.org/10.1016/j.surfcoat.2017.06.031 (2017)

Cui, LY, Qin, PH, Huang, XL, Yin, ZZ, et al. “Electrodeposition of TiO2 Layer-by-Layer Assembled Composite Coating and Silane Treatment on Mg Alloy for Corrosion Resistance.” Surf. Coat. Technol., 324 560–568. https://doi.org/10.1016/j.surfcoat.2017.06.015 (2017)

Naguib, HM, Ahmed, MA, Abo-Shanab, ZL, “Studying the Loading Impact of Silane Grafted Fe2O3 Nanoparticles on Mechanical Characteristics of Epoxy Matrix.” Egypt. J. Pet., 28 27–34. https://doi.org/10.1016/j.ejpe.2018.10.001 (2019)

Brusciotti, F, Batan, A, De Graeve, I, Wenkin, M, et al. “Characterization of Thin Water-Based Silane Pre-treatments on Aluminium with the Incorporation of Nano-dispersed CeO2 Particles.” Surf. Coat. Technol., 205 603–613. https://doi.org/10.1016/j.surfcoat.2010.07.052 (2010)

Alibakhshi, E, Akbarian, M, Ramezanzadeh, M, Ramezanzadeh, B, et al. “Evaluation of the Corrosion Protection Performance of Mild Steel Coated with Hybrid Sol-Gel Silane Coating in 3.5 wt% NaCl Solution.” Prog. Org. Coat., 123 190–200. https://doi.org/10.1016/j.porgcoat.2018.07.008 (2018)

Koh, SE, Delley, B, Medvedeva, JE, et al. “Quantum Chemical Analysis of Electronic Structure and n- and p-type Charge Transport in Perfluoroarene-Modified Oligothiophene Semiconductors.” J. Phys. Chem. B., 110 24361–24370. https://doi.org/10.1021/jp064840x (2006)

Delley, B, “Time Dependent Density Functional Theory with DMol3.” J. Phys. Condens. Mat., 22 384208–384213. https://doi.org/10.1088/0953-8984/22/38/384208 (2010)

Yang, LX, Cao, XL, Wu, YT, et al. “Improvement of Corrosion Resistance and Mechanism Analysis for Self-assembled Vinyltriethoxysilane (VS) Films on Low Carbon Steel Using a Novel Chemical Etching Method.” Corros. Sci., 177 109002–109015. https://doi.org/10.1016/j.corsci.2020.109002 (2020)

Alibakhshi, E, Ghasemi, E, Mahdavian, M, “The Influence of Surface Modification of Lithium Zinc Phosphate Pigment on Corrosion Inhibition of Mild Steel and Adhesion Strength of Epoxy Coating.” J. Sol-Gel Sci. Technol., 72 359–368. https://doi.org/10.1007/s10971-014-3441-2 (2014)

Rostami, M, Mohseni, M, “Investigating the Effect of pH on the Surface Chemistry of an Amino Silane Treated Nano Silica.” Pigm. Resin Technol., 40 363–373. https://doi.org/10.1108/03699421111180509 (2011)

Palanivel, V, Zhu, DQ, Van Ooij, WJ, “Nanoparticle-Filled Silane Films as Chromate Replacements for Aluminum Alloys.” Prog. Org. Coat., 47 384–392. https://doi.org/10.1016/j.porgcoat.2003.08.015 (2003)

Zhu, DQ, Van Ooij, WJ, “Structural Characterization of Bis-[triethoxysilylpropyl]tetrasulfide and Bis-[trimethoxysilylpropyl]amine Silanes by Fourier-transform Infrared Spectroscopy and Electrochemical Impedance Spectroscopy.” J. Adhes. Sci. Technol., 16 1235–1260. https://doi.org/10.1163/156856102320256873 (2002)

Ghanbari, A, Attar, MM, “A Study on the Anticorrosion Performance of Epoxy Nanocomposite Coatings Containing Epoxy-Silane Treated Nano-Silica on Mild Steel Substrate.” J. Ind. Eng. Chem., 23 145–153. https://doi.org/10.1016/j.jiec.2014.08.008 (2015)

Bryuzgin, EV, Klimov, VV, Repin, SA, Navrotskiy, AV, et al. “Aluminum Surface Modification with Fluoroalkyl Methacrylate-Based Copolymers to Attain Superhydrophobic Properties.” Appl. Surf. Sci., 419 454–459. https://doi.org/10.1016/j.apsusc.2017.04.222 (2017)

Yang, LX, Zhang, YX, Lei, XL, Liu, MX, “Effect of Solution Concentration on the Structures and Corrosion Inhibition Behavior of γ-APS Films Fabricated on Surface of Low Carbon Steel.” J. Wuhan Univ. Technol., 28 224–230. https://doi.org/10.1007/s11595-013-0669-6 (2013)

Wenzel, RN, “Resistance of Solid Surfaces to Wetting by Water.” Ind. Eng. Chem., 28 988–994. https://doi.org/10.1021/ie50320a024 (1936)

Acknowledgments

This work is supported by National Nature Science Foundation of China (Grant No. 41931295), Engineering Research Center of Nano-Geo Materials of Ministry of Education and China University of Geosciences (Grant No. NGM2018KF015 and NGM2020KF011).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, L., Xiao, Y., Chen, S. et al. Influence of nano-silica doping on the growth behavior and corrosion resistance of γ-APS silane films fabricated by electrochemical-assisted deposition. J Coat Technol Res 20, 333–346 (2023). https://doi.org/10.1007/s11998-022-00674-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-022-00674-2