Abstract

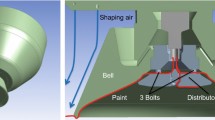

An electrostatic rotating bell atomizer was used to produce a spray of a 20 wt% aqueous glycerol solution. Droplet size distributions were measured by photographing droplets in-flight and using image analysis software to measure their diameters. Increasing the rotational speed of the bell-cup resulted in a decrease in the average droplet diameter. The fraction of area covered by spray droplets was measured for various bell-cup speeds using a high-speed camera positioned behind a vertical glass substrate on which the liquid was sprayed. An analytical model, based on probability theory, was used to predict the fraction of surface covered solely using the droplet flux and the droplet size. Results from the model were compared to experimentally measured fractions of surface coverage and showed good agreement. The minimum theoretical film thickness assuming full coverage was derived from the probabilistic model. When the minimum theoretical film thickness was divided by the droplet diameter, it was found to be only dependent on the spread factor. Experiments to measure the fraction of area covered were also conducted using an automotive paint. Increasing the paint flow rate increased the fraction of area covered. Increasing rotational speed reduced splat size but had little effect on coverage. Increasing shaping air 1 flow rate reduced splat size and increased surface coverage significantly. Application of an electrostatic potential increased splat diameter but enhanced surface coverage only slightly.

Similar content being viewed by others

Abbreviations

- A :

-

Area (µm2)

- c :

-

Shape parameter for Burr distribution

- D :

-

Diameter (µm)

- E :

-

Eccentricity

- F b :

-

Fraction of area not covered

- F c :

-

Fraction of area covered

- h :

-

Thickness of liquid film (µm)

- k :

-

Shape parameter for Burr distribution

- ME:

-

Margin of error

- \(\dot{N}\) :

-

Local droplet flux (droplet/s)

- n :

-

Number of droplets

- P :

-

Perimeter

- \(\hat{p}\) :

-

Estimate of proportion

- s :

-

Standard deviation

- t :

-

Time (s)

- U :

-

Droplet impact velocity (m/s)

- V :

-

Volume (µm3)

- x :

-

Random variable

- z :

-

Confidence level

- Re:

-

Reynolds number

- We:

-

Weber number

- α :

-

Scale parameter for Burr distribution

- β :

-

Impact parameter

- \(\epsilon\) :

-

\(= A_{\text{av}} /A_{\text{s}}\)

- μ :

-

Viscosity (mPa s)

- ξ :

-

Droplet spread factor

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension (mN/m)

- τ :

-

Minimum time for full coverage

- 20:

-

Surface mean

- 98:

-

98% Coverage

- av:

-

Arithmetic mean

- d:

-

Droplet

- f:

-

Fluid

- i :

-

Number

- n :

-

Number of droplets

- s:

-

Substrate

- splat:

-

Splat

- th:

-

Theoretical

References

Streitberger, H.J, Dössel, K.F, Automotive Paints and Coatings, 2nd ed. (2008).

Stevenin, C, Béreaux, Y, Charmeau, J-Y, Balcaen, J, “Shaping Air Flow Characteristics of a High-Speed Rotary-Bell Sprayer for Automotive Painting Processes.” J. Fluids Eng., 137 (11) (2015). https://doi.org/10.1115/1.4030703

Domnick, J, Thieme, M, “Atomization Characteristics of High-Speed Rotary Bell Atomizers.” At. Sprays, 16 (8) 857–874 (2006). https://doi.org/10.1615/AtomizSpr.v16.i8.10

Andersson, B, et al., “Modified TAB Model for Viscous Fluids applied to Breakup in Rotary Bell Spray Painting.” J. Mech. Eng. Autom., 3 (2) 54–61 (2013). https://doi.org/10.5923/j.jmea.20130302.05

Im, K, Lai, M, Yoon, S, “Spray Characteristics on the Electrostatic Rotating Bell Applicator.” KSME Int. J., 17 (12) 2053–2065 (2003). https://doi.org/10.1007/bf02982446

Atkar, PN, Greenfield, A, Conner, DC, Choset, H, Rizzi, AA, “Uniform Coverage of Automotive Surface Patches.” Int. J. Rob. Res., 24 (11) 883–898 (2005). https://doi.org/10.1177/0278364905059058

Domnick, J, Scheibe, A, Ye, Q, “The Simulation of the Electrostatic Spray Painting Process with High-Speed Rotary Bell Atomizers. Part I: Direct Charging.” Part. Part. Syst. Charact., 22 (2) 141–150 (2005). https://doi.org/10.1002/ppsc.200400968

Saranjam, N, Chandra, S, Mostaghimi, J, Fan, H, Simmer, J, “Orange Peel Formation due to Surface Tension-Driven Flows within Drying Paint Films.” J. Coat. Technol. Res., 13 (3) 413–426 (2016). https://doi.org/10.1007/s11998-015-9752-6

Arikan, MAS, Balkan, T, “Process Simulation and Paint Thickness Measurement for Robotic Spray Painting.” CIRP Ann., 50 (1) 291–294 (2001). https://doi.org/10.1016/S0007-8506(07)62124-6

Conner, DC, Greenfield, A, Atkar, PN, Rizzi, AA, Choset, H, “Paint Deposition Modeling for Trajectory Planning on Automotive Surfaces.” IEEE Trans. Autom. Sci. Eng., 2 (4) 381–392 (2005). https://doi.org/10.1109/TASE.2005.851631

Di Domenico, J, Henshaw, P, “The Effects of Basecoat Bell Application Parameters on Elements of Appearance for an Automotive Coatings Process.” J. Coat. Technol. Res., 9 (6) 675–686 (2012). https://doi.org/10.1007/s11998-012-9414-x

Corbeels, PL, Senser, DW, Lefebvre, AH, “Atomization Characteristics of a Highspeed Rotary-Bell Paint Applicator.” At. Sprays, 2 (2) 87–99 (1992). https://doi.org/10.1615/AtomizSpr.v2.i2.20

Im, K-S, Lai, M-C, Liu, Y, Sankagiri, N, Loch, T, Nivi, H, “Visualization and Measurement of Automotive Electrostatic Rotary-Bell Paint Spray Transfer Processes.” J. Fluids Eng., 123 (2) 237–245 (2000). https://doi.org/10.1115/1.1359210

Ray, R, Henshaw, P, “Evaporation of Clearcoat Solvents from a Rotary Bell Atomizer and its Relationship with Bell Speed, Flow Rate, and Electrostatic Potential.” J. Coat. Technol. Res., 15 (1) 41–49 (2018). https://doi.org/10.1007/s11998-017-9972-z

Takamura, K, Fischer, H, Morrow, NR, “Physical Properties of Aqueous Glycerol Solutions.” J. Pet. Sci. Eng., 98--99 50–60 (2012). https://doi.org/10.1016/J.PETROL.2012.09.003

Otsu, N, “A Threshold Selection Method from Gray-Level Histograms.” IEEE Trans. Syst. Man. Cybern., 9 (1) 62–66 (1979). https://doi.org/10.1109/TSMC.1979.4310076

Cochran, WG, Sampling Techniques, 3rd ed. Wiley, New York (1977)

Dalili, A, Sidawi, K, Chandra, S, “Surface Coverage by Impact of Droplets From a Monodisperse Spray.” J. Coat. Technol. Res., 17 (1) 207–217 (2020). https://doi.org/10.1007/s11998-019-00258-7

Walpole, RE, Probability & Statistics for Engineers & Scientists. Pearson Education Limited, Harlow (2016)

Burr, IW, “Cumulative Frequency Functions.” Ann. Math. Stat., 13 (2) 215–232 (1942). https://doi.org/10.1214/aoms/1177731607

Tadikamalla, PR, “A Look at the Burr and Related Distributions.” Int. Stat. Rev., 48 (3) 337–344 (1980). https://doi.org/10.2307/1402945

Laan, N, de Bruin, KG, Bartolo, D, Josserand, C, Bonn, D, “Maximum Diameter of Impacting Liquid Droplets.” Phys. Rev. Appl., 2 (4) 44018 (2014). https://doi.org/10.1103/PhysRevApplied.2.044018

Acknowledgments

The authors thankfully acknowledge that funding for this project was provided by the Natural Sciences and Engineering Research Council (NSERC) of Canada and by Magna Exteriors. Experiments were carried out at the test facilities of Magna Exteriors. We are grateful for the assistance of Dr. Amirreza Amighi in carrying out droplet size measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sidawi, K., Moroz, P. & Chandra, S. On surface area coverage by an electrostatic rotating bell atomizer. J Coat Technol Res 18, 649–663 (2021). https://doi.org/10.1007/s11998-020-00430-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00430-4