Abstract

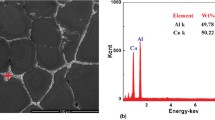

Herein, Al-Si-Cu aluminum alloy was prepared and the effect of forging on the microstructure and mechanical properties of novel Al-9Si-5Cu-0.2Zr-0.1Sr-0.16Ti-0.1Ce cast aluminum alloy was investigated. The microstructure analyses show that after forging, the casting defects disappeared, and the irregular Si-eutectic was spheroidized and randomly distributed. The coarse intermetallic compounds (IMCs) gradually dissolved during the solution treatment, and the increased supersaturation of the matrix promoted precipitation kinetics, leading to the coexistence of dense fine θ and θ' strengthening phases. Moreover, the dislocation strengthening effect for the forged alloy was enhanced. The mechanical tests show that compared to the as-cast alloy, the mechanical properties of the forged alloy including the hardness, yield strength, tensile strength, and plasticity were improved by optimizing the microstructure.

Similar content being viewed by others

References

H. Peng, C. Chen, H.Y. Zhang et al., Recent Development of Improved Clinching Process, Int. J. Adv Manuf. Technol., 2020, 110, p 1–31.

R. Yi, C. Chen, Y. Li et al., The Bonding Between Glass and Metal, Int. J. Adv Manuf. Technol., 2020, 111, p 1–21.

C. Chen, H.Y. Zhang, Y.Q. Xu et al., Investigation of the Flat-Clinching Process for Joining Three-Layer Sheets on Thin-Walled Structures, Thin Wall Struct., 2020, 157, p 107034.

B. Donadoni, G.L.D. Gouveia, A. Garcia et al., A Comparison of Experimental Time-Secondary Dendritic Spacing and Coarsening Models for Al-Si-Cu Alloys, J. Manuf. Process., 2020, 54, p 14–18.

J.D. Poplawsky, B.K. Milligan, L.F. Allard et al., The Synergistic Role of Mn and Zr/Ti in Producing θ′/L12 Co-precipitates in Al-Cu Alloys, Acta Mater., 2020, 194, p 577–586.

A.K. Jha and S.N. Ojha, Deformation Behavior of Aluminum-Silicon (Al-Si) Alloy During Forging Under Various Processing Conditions, Mater. Today Proc., 2018, 5, p 26955–26960.

C.G. Kang and J.S. Choi, Effect of Gate Shape and Forging Temperature on the Mechanical Properties in the Injection Forging Process of Semi-solid Aluminum Material, J. Mater. Process. Technol., 1998, 73, p 251–263.

C.G. Kang, J.S. Choi et al., The Effect of Strain Rate on Macroscopic Behavior in the Compression Forming of Semi-solid Aluminum Alloy, J. Mater. Process. Technol., 1999, 88, p 159–168.

F.F. Wu, S.T. Li, G.A. Zhang et al., Microstructural Evolution and Mechanical Properties of Hypereutectic Al-Si Alloy Processed by Liquid Die Forging, Bull. Mater. Sci., 2014, 37, p 1153–1157.

P. Luo, D.T. Mcdonald, W. Xu et al., A Modified Hall-Petch Relationship in Ultrafine-Grained Titanium Recycled from Chips by Equal Channel Angular Pressing, Scr. Mater., 2012, 66, p 785–788.

C.Y. Zhu, X.J. Xu, H. Wang et al., Effect of Mg on Microstructure and Properties of Al-8.95Zn-(1.9–2.6)Mg-1.18Cu-0.44Zr Rolled Aluminum Alloy, Mater. Res. Express, 2018, 5, p 065803.

X.J. Xu, H.H. Shao, J. Gao et al., Effect of Sic Film on Tensile Properties of Nanostructured Ti Produced by Compressive Deformation at Liquid-Nitrogen Temperature, Mater. Sci. Eng. A, 2008, 493, p 195–201.

K.M. Youssef, R.O. Scattergood, K.L. Murty et al., Nanocrystalline Al-Mg Alloy with Ultrahigh Strength and Good Ductility, Scr. Mater., 2006, 54, p 251–256.

S.C. Wang and M.J. Starink, Precipitates and Intermetallic Phases in Precipitation Hardening Al-Cu-Mg-(Li) Based Alloys, Int. Mater. Rev., 2005, 50, p 193–215.

S.K. Varma, D. Salas, E. Corral et al., Microstructural Development During Aging of 2014 Aluminum Alloy Composite, J. Mater. Sci., 1999, 34, p 1855–1863.

M. Okayasu and S. Go, Precise Analysis of Effects of Aging on Mechanical Properties of Cast ADC12 Aluminum Alloy, Mater. Sci. Eng. A, 2015, 638, p 208–218.

A. Reis, Z. Xu, R.V. Tol et al., Modelling Feeding Flow Related Shrinkage Defects in Aluminum Castings, J. Mater. Process. Technol., 2012, 14, p 1–7.

Y. Cao, X. Chen, Z. Wang et al., Effect of Cd Micro-addition on Microstructure and Mechanical Properties in Ternary Al-Si-Cu Alloy, J. Alloys Compd., 2020, 851, p 156739.

K. Lee, Y.N. Kwon and S. Lee, Effects of Eutectic Silicon Particles on Tensile Properties and Fracture Toughness of A356 Aluminum Alloys Fabricated by Low-Pressure-Casting, Casting-Forging, and Squeeze-Casting Processes, J. Alloys Compd., 2008, 461, p 532–541.

C.L. Xu, H.Y. Wang, Y.F. Yang et al., Effect of Al-P-Ti-TiC-Nd2O3 Modifier on the Microstructure and Mechanical Properties of Hypereutectic Al-20 wt.%Si Alloy, Mater. Sci. Eng. A, 2007, 452, p 341–346.

Q. Li, T. Xia, Y. Lan et al., Effects of Rare Earth Er Addition on Microstructure and Mechanical Properties of Hypereutectic Al-20% Si Alloy, J. Alloys Compd., 2013, 588, p 97–102.

C. Liang, Z.H. Chen, Z.Y. Huang et al., Optimizing Microstructures and Mechanical Properties of Hypereutectic Al-18%Si Alloy via Manipulating its Parent Liquid State, Mater. Sci. Eng. A, 2017, 690, p 387–392.

Y.M. Han, A.M. Samuel, F.H. Samuel, S. Valtierra and H.W. Doty, Effect of Solution Heat Treatment Type on the Dissolution of Copper Phases in Al-Si-Cu-Mg Type Alloys, AFS Trans., 2008, 116, p 79–90.

E. Sjölander and S. Seifeddine, The Heat Treatment of Al-Si-Cu-Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210, p 1249–1259.

E. Feyzullahoglu, A.T. Ertürk and E.A. Güven, Influence of Forging and Heat Treatment on Wear Properties of Al-Si and Al-Pb Bearing Alloys in Oil Lubricated Conditions, Trans. Nonferr. Met. Soc., 2013, 23, p 3575–3583.

A.M. Cassell, J.D. Robson, C.P. Race et al., Dispersoid Composition in Zirconium Containing Al-Zn-Mg-Cu (AA7010) Aluminium Alloy, Acta Mater., 2019, 169, p 135–146.

Y. Wang, G. Zhao, X. Xu et al., Microstructures and Mechanical Properties of Spray Deposited 2195 Al-Cu-Li Alloy Through Thermo-mechanical Processing, Mater. Sci. Eng. A, 2018, 727, p 78–89.

S.K. Shaha, F. Czerwinski, W. Kasprzak et al., Ageing Characteristics and High-Temperature Tensile Properties of Al-Si-Cu-Mg Alloys with Micro-additions of Mo and Mn, Mater. Sci. Eng. A, 2017, 684, p 726–734.

Y.Z. Hou, L. Chen, Z.G. Li et al., Effects of Artificial Aging on Microstructure, Mechanical Properties and Stress Corrosion Cracking of a Novel High Strength 7A99 Al Alloy, Mater. Sci. Eng. A, 2020, 780, p 139217.

D. Pan, L. Xian, Y. Yang et al., Nano-scale Precipitate Evolution and Mechanical Properties of 7085 Aluminum Alloy During Thermal Exposure, Mater. Sci. Eng. A, 2018, 729, p 411–422.

B.M. Christopher, C.D. David and N.S. David, Coarsening Resistance at 400 °C of Precipitation-Strengthened Al-Zr-Sc-Er Alloys, Acta Mater., 2001, 59, p 7029–7042.

C. Schlesier and E. Nembach, Strengthening of Aluminum-Lithium Alloys by Long-Range Ordered δ’ Precipitates, Acta Metall. Mater., 1995, 43(3983), p 3990.

A. Shyam, S. Roy, D. Shin et al., Elevated Temperature Microstructural Stability in Cast AlCuMnZr Alloys Through Solute Segregation, Mater. Sci. Eng. A, 2019, 765, p 138279.

S. Roy, L.F. Allard, A. Rodriguez et al., Comparative Evaluation of Cast Aluminum Alloys for Automotive Cylinder Heads: Part II-Mechanical and Thermal Properties, Metall. Mater. Trans. A, 2017, 48, p 2543–2562.

B.K. Milligan, S. Roy, C.S. Hawkins et al., Impact of Microstructural Stability on the Creep Behavior of cast Al-Cu Alloys, Mater. Sci. Eng. A, 2020, 772, p 138697.

Acknowledgments

Thanks to the financial supports from the Key Projects of Equipment Pre-research Foundation of the Ministry of Equipment Development of the Central Military Commission of China (No: 6140922010201) and the Key Projects of Research and Development of Zhenjiang (GY2018021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Xu, X., Zhang, R. et al. Effect of Forging on Microstructure and Properties of Al-9Si-5Cu-0.2Zr-0.1Sr-0.16Ti-0.1Ce Cast Aluminum Alloy. J. of Materi Eng and Perform 31, 105–112 (2022). https://doi.org/10.1007/s11665-021-06214-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06214-0