Abstract

This research work was carried out with the aim of obtaining the optimum combination of the novel linear low-density polyethylene/ethylene vinyl acetate (LLDPE/EVA)nanocomposites by incorporation reduced graphene oxide (rGO) as reinforcement andLLDPE-g-MA as compatibilizerwith the new solution method.Different samples were synthesized by various amounts of rGO from 0.1 phr to 1 phr, 80 phr LLDPE, 5 phrLLDPE-g-MA, and 20 phr EVA.Thermal, rheological, mechanical, and morphological properties were investigated. Results showed that the modulus, elongation-at-break, and tensile strength increased significantly with the increase of rGO content in the presence of LLDPE-g-MA. Transmission electron microscopy (TEM) images showed that LLDPE-g-MA can cause a better dispersion of rGO in the polymeric matrix by creating an interface between LLDPE, LLDPE-g-MA, and EVA. In addition, the field emission scanning electron microscopy (FESEM) images showed that with the increase in the amount of rGO, the particlediameter of the EVA dispersed phase decreased significantly, which is the result of the interactions between the carbonic nanofiller and the LLDPE-g-MA compatibilizer.

Similar content being viewed by others

References

Qureshi FS, Amin MB, Maadhah AG, Hamid SH (1990) Weather induced degradation of linear low density polyethylene (LLDPE): mechanical properties. J Polym Eng 9:67–84

Vafa E, Bazargan-lari R, Bahrololoom ME, Amani AM (2022) Effect of polyvinyl alcohol concentration on biomedical application of chitosan/bioactive glass composite coated on AZ91D magnesium alloy. Mater Chem Phys 291:126650

McPherson J, Mogul H (1998) Underlying physics of the thermochemical E model in describing low-field time-dependent dielectric breakdown in SiO2 thin films. J Appl Phys 84:1513–1523

Du X, Zhao M, Pan N, Wang S, Xia X, Zhang D (2021) Tracking aggregation behaviour and gel properties induced by structural alterations in myofibrillar protein in mirror carp (Cyprinus carpio) under the synergistic effects of pH and heating. Food Chem 362:130222

Pérez R, Rojo E, Fernández M, Leal V, Lafuente P, Santamaria A (2005) Basic and applied rheology of m-LLDPE/LDPE blends: Miscibility and processing features. Polymer 46:8045–8053

Ajji A, Sammut P, Huneault M (2003) Elongational rheology of LLDPE/LDPE blends. J Appl Polym Sci 88:3070–3077

Vafa E, Tayebi L, Abbasi M, Azizli MJ, Bazargan-Lari R, Talaiekhozani A, Zareshahrabadi Z, Vaez A, Amani AM, Kamyab H, Chelliapan S (2022) A better roadmap for designing novel bioactive glasses: effective approaches for the development of innovative revolutionary bioglasses for future biomedical applications. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-24176-1

Hoseinzadeh A, Ghoddusi Johari H, Anbardar MH, Tayebi L, Vafa E, Abbasi M, Vaez A, Golchin A, Amani AM, Jangjou A (2022) treatment of intractable diseases using nanoparticles to interfere with vascular supply and angiogenic process. Eur J Med Res 27:232

Jangjou A, Zareshahrabadi Z, Abbasi M, Talaiekhozani A, Kamyab H, Chelliapan S, Vaez A, Golchin A, Tayebi L, Vafa E, Amani AM, Faramarzi JH (2022) Time to conquer fungal infectious diseases: employing nanoparticles as powerful and versatile antifungal nanosystems against a wide variety of fungal species. Sustainability 14:12942

Zhang S, Zhang G, Qiu J, Jiang Z, Xing H, Li M, Tang T (2018) The effect of nanosized carbon black on the morphology and sc-CO2 foaming behavior of LLDPE/PS blends at semi-solid state. Compos Commun 7:30–35

Sari NH, Sanjay M, Arpitha G, Pruncu CI, Siengchin S (2019) Synthesis and properties of pandanwangi fiber reinforced polyethylene composites: Evaluation of dicumyl peroxide (DCP) effect. Compos Commun 15:53–57

Chandra RS (2015) Applications of graphene and graphene-oxide based nanomaterials, bookChapter. Elsevier, UK

Azizli MJ, Ghadami A, Vafa E, Rezaeeparto K, Parham S, Mokhtary M, Jahankhah Z, Azizli F, Bazargan-Lari R, Amani AM (2023) Compatibilization of immiscible pa6/pla nanocomposites using graphene oxide and PTW compatibilizer for high thermal and mechanical applications. J Polym Env 31:4193–4209

Maqbool M, Aftab W, Bashir A, Usman A, Guo H, Bai S (2022) Engineering of polymer-based materials for thermal management solutions. Compos Commun 29:101048

Khonakdar H, Wagenknecht U, Jafari S, Hässler R, Eslami H (2004) Dynamic mechanical properties and morphology of polyethylene/ethylene vinyl acetate copolymer blends. Adv Polym Technol 23:307–315

Kontou E, Niaounakis M (2006) Thermo-mechanical properties of LLDPE/SiO2 nanocomposites. Polymer 47:1267–1280

Krupa I, Luyt A (2001) Thermal and mechanical properties of extruded LLDPE/wax blends. Polym Degrad Stabil 73:157–161

Pichaiyut S, Wisunthorn S, Thongpet C, Nakason C (2016) Novel ternary blends of natural rubber/linear low-density polyethylene/thermoplastic starch: influence of epoxide level of epoxidized natural rubber on blend properties. Iran Polym J 25:711–723

Duc BN, Son Y (2020) Enhanced dispersion of multi walled carbon nanotubes by an extensional batch mixer in polymer/MWCNT nanocomposites. Compos Commun 21:100420

Wu S, Chi B, Yan H, Shen J (2006) A study of LLDPE functionalized through ultraviolet irradiation and interfacial interaction of PA66/functionalized LLDPE blends. J Appl Polym Sci 99:2029–2032

Azizli MJ, Barghamadi M, Rezaeeparto K, Mokhtary M, Parham S, Goodarzi V, Soltani S (2020) Enhancement of thermal, morphological, and mechanical properties of compatibilized based on PA6-enriched graphene oxide/EPDM-g-MA/CR: Graphene oxide and EPDM-g-MA compatibilizer role. J Appl Polym Sci 138:e49901

Azizli MJ, Mokhtary M, Khonakdar HA, Goodarzi V (2020) "Compatibilizer/graphene/carboxylated acrylonitrile butadiene rubber (XNBR)/ethylenepropylenediene monomer (EPDM) nanocomposites: Morphology, compatibility, rheology and mechanical properties. J Appl Polym Sci 137:e49331

Jurkowski B, Kelar K, Ciesielska D (1998) Influence of chemical and mechanical compatibilization on structure and properties of polyethylene/polyamide blends. J Appl Polym Sci 69:719–727

Fernandes JC, Castro L, Mareau V, Pessan L, Gonon L (2018) New insights on the compatibilization of PA6/ABS blends: A co-localized AFM-Raman study. Polymer 146:151–160

Cataño L, Albano C, Karam A, Perera R, Silva P ( 2007) Thermal stability evaluation of PA6/LLDPE/SEBS-g-DEM blends. Macromol Symp 257:147–157

Huang J, Keskkula H, Paul D (2006) Comparison of the toughening behavior of nylon 6 versus an amorphous polyamide using various maleated elastomers. Polymer 47:639–651

Cai Y, Jiang JS, Zheng B, Xie MR (2013) Synthesis and properties of magnetic sensitive shape memory Fe3O4/poly (ε-caprolactone)-polyurethane nanocomposites. J Appl Polym Sci 127:49–56

Azizli M, Naderi G, Bakhshandeh G, Soltani S, Askari F, Esmizadeh E (2014) Improvement in physical and mechanical properties of IIR/CR rubber blend organoclay nanocomposites. Rubber Chem Technol 87:10–20

Azizli MJ, Ziaee M, Rezaeinia S, Seyfi J, Mansourian-Tabaei M, Hoseinzadeh M, Azizli MH (2018) Studying the roles of nanoclay and blend composition on the improved properties of natural rubber/chloroprene composites. Polym Compos 39:1562–1574

Azizli MJ, Khonakdar HA, Mokhtary M, Goodarzi V (2019) Investigating the effect of organoclay montmorillonite and rubber ratio composition on the enhancement compatibility and properties of carboxylated acrylonitrile-butadiene rubber/ethylene-propylene-diene monomer hybrid elastomer nanocomposites. J Polym Res 26:1–20

Hwang TY, Yoo Y Lee JW (2012) Electrical conductivity, phase behavior, and rheology of polypropylene/polystyrene blends with multi-walled carbon nanotube. Rheol Acta 51:623–636

Ville J, Médéric P, Huitric J, Aubry T (2012) Structural and rheological investigation of interphase in polyethylene/polyamide/nanoclay ternary blends. Polymer 53:1733–1740

Mahallati P, Arefazar A, Naderi G (2010) Thermoplastic elastomer nanocomposites based on PA6/NBR. Int Polym Process 25:132–138

Wang H, Qiu Z (2012) Crystallization kinetics and morphology of biodegradable poly (l-lactic acid)/graphene oxide nanocomposites: Influences of graphene oxide loading and crystallization temperature. Thermochim Acta 527:40–46

Ma HL, Zhang HB, Hu QH, Li WJ, Jiang ZG, Yu ZZ, Dasari A (2012) Functionalization and Reduction of Graphene Oxide with p-Phenylene Diamine for Electrically Conductive and Thermally Stable Polystyrene Composites. ACS Appl Mater Interfaces 4:1948–1953

Azizli MJ, Barghamadi M, Rezaeeparto K, Mokhtary M, Parham S (2020) Compatibility, mechanical and rheological properties of hybrid rubber NR/EPDM-g-MA/EPDM/graphene oxide nanocomposites: Theoretical and experimental analyses. Compos Commun 22:100442

Azizli MJ, Barghamadi M, Rezaeeparto K, Parham S (2022) Improvement of mechanical, morphological and thermal properties on PP-enriched graphene oxide/PP-g-MA/EPDM blend compatibilized: PP-g-MA compatibilizer and graphene oxide nanofiller role. J Polym Res 29:322

Raos G (2003) Application of the Christensen-Lo model to the reinforcement of elastomers by fractal fillers. Macromol Theory Simul 12:17–23

Zare Y (2016) A model for tensile strength of polymer/clay nanocomposites assuming complete and incomplete interfacial adhesion between the polymer matrix and nanoparticles by the average normal stress in clay platelets. RSC Adv 63:57969–57976

Budiansky B (1965) On the elastic moduli of some heterogeneous materials. J Mech Phys Solids 13:223–227

Azizli MJ, Barghamadi M. Rezaeeparto K. Parham S (2022) Improvement of mechanical, morphological and thermal properties on PP-enriched graphene oxide/PP-g-MA/EPDM blend compatibilized: PP-g-MA compatibilizer and graphene oxide nanofiller role. J Polym Res 29:1–16

Shen L, Li J (2005) Homogenization of a fibre/sphere with an inhomogeneous interphase for the effective elastic moduli of composites. Proc Math Phys Eng Sci P Roy Soc A-Math Phy 461:1475–1504

Zare Y (2015) Effects of interphase on tensile strength of polymer/CNT nanocomposites by Kelly–Tyson theory. Mech Mater 85:1–6

Jiang B, Weng G (2004) A generalized self-consistent polycrystal model for the yield strength of nanocrystalline materials. J Mech Phys Solids 52:1125–1149

Azizli MJ, Morshedi Dehaghi F, Nasrollahi B, Barghamadi M, Rezaeeparto K, Parham S, Mokhtary M, Ramakrishna S, Rezvani Ghomi E (2021) Analysis and modeling of modified styrene–acrylonitrile/carboxylated acrylonitrile butadiene rubber nanocomposites filled with graphene and graphene oxide: Interfacial interaction and nonlinear elastoplastic behavior. Polym Eng Sci 61:2894–2909

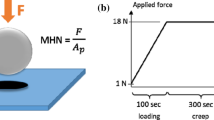

Münstedt H (2014) Rheological experiments at constant stress as efficient method to characterize polymeric materials. J Rheol 58:565–587

Liu X, Pan Y, Zheng G, Schubert DW (2016) Rheological and electrical behavior of poly (methyl methacrylate)/carbon black composites as investigated by creep recovery in shear. Compos Sci Technol 128:1–7

Azizli MJ, Abbasizadeh S, Hoseini M, Rezaeinia S, Azizli E (2017) Influence of blend composition and organic cloisite 15A content in the structure of isobutylene–isoprene rubber/ethylene propylene diene monomer composites for investigation of morphology and mechanical properties. J Compos Mate 51:1861–1873

Dharmaraj MM, Chakraborty BC, Begum S (2022) The effect of graphene and nanoclay on properties of nitrile rubber/polyvinyl chloride blend with a potential approach in shock and vibration damping applications. Iran Polym J 31:1129–1145

Baniasadi H, Seppälä J (2021) Novel long-chain aliphatic polyamide/surface-modified silicon dioxide nanocomposites: in-situ polymerization and properties. Mater Today Chem 20:100450

Alhabill F, Vaughan A, Andritsch T (2021) On nanocomposite fabrication: using rheology to characterize filler/polymer interactions in epoxy-based nanocomposites. Mater Today Chem 22:100559

Acknowledgements

L.T. acknowledges the partial support from National Institute of Dental & Craniofacial Research of the National Institutes of Health under award number R56 DE029191 and, the SazePaidarElahie (Linkran Industrial Group) Company gratefully is acknowledged by the authors. The authors also thank SazePaidarElahie (Linkran Industrial Group), Consulting rubber Engineers CO for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that there is no conflict of interest regarding the publication of this research paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azizli, M.J., Vafa, E., Rezaeeparto, K. et al. Impact on summation of reduced graphene oxide and compatibilization efficacy of LLDPE-g-MA on mechanical, thermal, morphological, and rheological properties of LLDPE/EVA nanocomposites. J Polym Res 30, 420 (2023). https://doi.org/10.1007/s10965-023-03800-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03800-9