Abstract

The aim of this work is synthesis a novel nanocomposite containing Polylactide (PLA) and polyamide 6 (PA6) reinforced with graphene oxide (GO) and poly ethylene-butyl acrylate-glycidyl methacrylate) (PTW) compatibilizer during solvent-based method. For this purpose, GO was added to the nanocomposite with 0.1, 0.3, 0.5, 0.7 and 1 phr. Morphology, rheology and mechanical properties of nanocomposites were studied with scanning electron microscopy (SEM), transmission electron microscopy (TEM) and (DMTA) which showed rougher fracture surface due to the presence of compatibilizer and an increase in the amount of graphene oxide and better dispersion of graphene oxide. The results of experimental and theoretical studies of mechanical properties showed that increasing the concentration of graphene oxide in the presence of PTW improved the tensile strength, impact strength and tensile modulus in the PA6/PTW/PLA system. The study of rheological properties showed an increase in storage modulus and complex viscosity, which also confirmed the role of PTW compatibilizer in better GO dispersion. So, PA6/PTW/PLA is a good candidate for mechanical and high thermal applications.

Similar content being viewed by others

Data availability

Data will available with request.

References

Patil A, Patel A, Purohit R (2017) An overview of polymeric materials for automotive applications. Mater Today: Proc 4(2):3807–3815

Vafa E et al (2022) Effect of polyvinyl alcohol concentration on biomedical application of chitosan/bioactive glass composite coated on AZ91D magnesium alloy. Mater Chem Phys 291:126650

Vafa E, Bazargan-Lari R (2021) Bovine serum albumin protected gold nanozymes as a novel anti-cancer nanodrug for acute T-type lymphoblastic leukemia treatment via effect on the expression of anti-apoptotic genes. Appl Biol Chem 64(1):86

Heidari F et al (2020) 3D construct of hydroxyapatite/zinc oxide/palladium nanocomposite scaffold for bone tissue engineering. J Mater Sci - Mater Med 31(10):85

Heidari F et al (2020) Nano-hydroxyapatite and nano-hydroxyapatite/zinc oxide scaffold for bone tissue engineering application. Int J Appl Ceram Technol 17(6):2752–2761

Raj A, Samuel C, Prashantha K (2020) Role of compatibilizer in improving the properties of PLA/PA12 blends. Front Mater 7:193

García-Masabet V et al (2019) PLA/PA bio-blends: induced morphology by extrusion. Polymers 12(1):10

Karimpour-Motlagh N et al (2019) An experimental and theoretical mechanistic analysis of thermal degradation of polypropylene/polylactic acid/clay nanocomposites. Polym Adv Technol 30(11):2695–2706

Tripathi N, Misra M, Mohanty AK (2021) Durable polylactic acid (PLA)-based sustainable engineered blends and biocomposites: recent developments, challenges, and opportunities. ACS Eng Au 1(1):7–38

Scaffaro R et al (2020) PLA-based functionally graded laminates for tunable controlled release of carvacrol obtained by combining electrospinning with solvent casting. React Funct Polym 148:104490

Scaffaro R, Maio A, Lopresti F (2019) Effect of graphene and fabrication technique on the release kinetics of carvacrol from polylactic acid. Compos Sci Technol 169:60–69

Imani F et al (2021) PLA electrospun nanofibers modified with polypyrrole-grafted gelatin as bioactive electroconductive scaffold. Polymer 218:123487

Pinto AM et al (2013) Biocompatibility of poly (lactic acid) with incorporated graphene-based materials. Colloids Surf, B 104:229–238

Basak S (2021) Redesigning the modern applied medical sciences and engineering with shape memory polymers. Adv Compos Hybrid Mater 4(2):223–234

Chen J et al (2022) Promotion of skin regeneration through co-axial electrospun fibers loaded with basic fibroblast growth factor. Adv Compos Hybrid Mater 5(2):1111–1125

Raj A, Prashantha K, Samuel C (2020) Compatibility in biobased poly (L-lactide)/polyamide binary blends: from melt-state interfacial tensions to (thermo) mechanical properties. J Appl Polym Sci 137(10):48440

Auras RA et al (2022) Poly (lactic acid): synthesis, structures, properties, processing, applications, and end of life. John Wiley & Sons, Hoboken

Nagarajan V, Mohanty A, Misra M (2016) ACS Sustain Chem Eng 4:2899–2916

Bayer IS (2017) Thermomechanical properties of polylactic acid-graphene composites: A state-of-the-art review for biomedical applications. Materials 10(7):748

Codou A et al (2018) Novel compatibilized nylon-based ternary blends with polypropylene and poly (lactic acid): MORPHOLOGY evolution and rheological behaviour. RSC Adv 8(28):15709–15724

Yu Y et al (2022) Interface nanoengineering of a core-shell structured biobased fire retardant for fire-retarding polylactide with enhanced toughness and UV protection. J Clean Prod 336:130372

Chen T et al (2020) Bio-based and biodegradable electrospun fibers composed of poly (L-lactide) and polyamide 4. Chin J Polym Sci 38:53–62

Chen R-Y et al (2015) Poly (lactic acid)/polypropylene and compatibilized poly (lactic acid)/polypropylene blends prepared by a vane extruder: analysis of the mechanical properties, morphology and thermal behavior. J Polym Eng 35(8):753–764

Hoseinzadeh A et al (2022) Effective treatment of intractable diseases using nanoparticles to interfere with vascular supply and angiogenic process. Eur J Med Res 27(1):232

Bouzouita A et al (2016) Design of highly tough poly (l-lactide)-based ternary blends for automotive applications. J Appl Polym Sci. https://doi.org/10.1002/app.43402

Samuel C, Raquez J-M, Dubois P (2013) PLLA/PMMA blends: a shear-induced miscibility with tunable morphologies and properties? Polymer 54(15):3931–3939

Wang P et al (2022) Effect of carbon nanotubes on the interface evolution and dielectric properties of polylactic acid/ethylene–vinyl acetate copolymer nanocomposites. Adv Compos Hybrid Mater 5(2):1100–1110

Nofar M et al (2019) Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol 125:307–360

Mousavi SM et al (2017) Polyethylene terephthalate/acryl butadiene styrene copolymer incorporated with oak shell, potassium sorbate and egg shell nanoparticles for food packaging applications: control of bacteria growth, physical and mechanical properties. Polym Renewable Resour 8(4):177–196

Rudresh BM, Ravi Kumar BN, Madhu D (2019) Combined effect of micro- and nano-fillers on mechanical, thermal, and morphological behavior of glass–carbon PA66/PTFE hybrid nano-composites. Adv Compos Hybrid Mater 2(1):176–188

Marchildon K (2011) Polyamides–still strong after seventy years. Macromol React Eng 5(1):22–54

Rostamizadeh S et al (2009) Solvent-free chemoselective synthesis of some novel substituted 2-arylbenzimidazoles using amino acid-based prolinium nitrate ionic liquid as catalyst. J Heterocycl Chem 46(1):74–78

Deopura B et al (2008) Polyesters and polyamides. Elsevier, Amsterdam

Dechet MA et al (2020) Development of poly (Llactide)(PLLA) microspheres precipitated from triacetin for application in powder bed fusion of polymers. Addit Manuf 32:100966

Vafa E et al (2022) A better roadmap for designing novel bioactive glasses: effective approaches for the development of innovative revolutionary bioglasses for future biomedical applications. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-24176-1

Bijarimi M et al (2019) Preparation and characterization of poly (lactic acid)(PLA)/polyamide 6 (PA6)/graphene nanoplatelet (GNP) blends bio-based nanocomposites. Mater Res Express 6(5):055044

Pinto AM et al (2013) Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly (lactic acid) films. Polym Int 62(1):33–40

Maio A et al (2021) An overview of functionalized graphene nanomaterials for advanced applications. Nanomaterials 11(7):1717

Azizl MJ et al (2021) Graphene oxide and graphene hybrid nanocomposites based on compatibilized PP/PTW/EVA: effect of nanofiller and compatibilizer on the modeling of viscoplastic behavior. J Polym Res 28(8):1–21

Rahimipour S et al (2021) Preparation and properties of enhanced bio-based PLA/PA6/graphene nanocomposites in the presence of an ester-amide exchange catalyst. J Polym Environ 29(7):2302–2309

Fu X, Yao C, Yang G (2015) Recent advances in graphene/polyamide 6 composites: a review. RSC Adv 5(76):61688–61702

Azizli MJ et al (2021) Analysis and modeling of modified styrene–acrylonitrile/carboxylated acrylonitrile butadiene rubber nanocomposites filled with graphene and graphene oxide: interfacial interaction and nonlinear elastoplastic behavior. Polym Eng Sci 61(11):2894–2909

Mousavi M et al (2018) Erythrosine adsorption from aqueous solution via decorated graphene oxide with magnetic iron oxide nano particles: kinetic and equilibrium studies. Acta Chim Slov 65(4):882–894

Hu C et al (2017) Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: reduced graphene oxide or carbon nanotubes. J Mater Chem C 5(9):2318–2328

Jangjou A et al (2022) Time to conquer fungal infectious diseases: employing nanoparticles as powerful and versatile antifungal nanosystems against a wide variety of fungal species. Sustainability 14(19):12942

O’Neill A, Bakirtzis D, Dixon D (2014) Polyamide 6/Graphene composites: the effect of in situ polymerisation on the structure and properties of graphene oxide and reduced graphene oxide. Eur Polymer J 59:353–362

Azizli MJ et al (2023) Preparation, characterization, and compatibilization of novel rubber nanocomposites for mechanical applications: relationship between electrical properties, morphology, and rheology. J Adhesion Sci Technol. https://doi.org/10.1080/01694243.2023.2166613

Wang Y-L et al (2010) Polyamide-6/poly (lactic acid) blends compatibilized by the maleic anhydride grafted polyethylene-octene elastomer. Polym-Plast Technol Eng 49(12):1241–1246

Zhang C, Dai G (2007) Mechanical properties and reactions of PBT/PTW blends. J Mater Sci 42(24):9947–9953

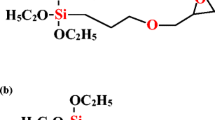

Zou W et al (2020) Effect of ethylene–butylacrylate–glycidyl methacrylate on compatibility properties of poly (butylene terephthalate)/thermoplastic polyurethane blends. ES Energy Environ 9(5):67–73

Yang F, Mu M, Zhang K (2021) Ultralong NiSe nanowire anchored on graphene nanosheets for enhanced electrocatalytic performance of triiodide reduction. RSC Adv 11(44):27681–27688

Panahi-Sarmad M, Razzaghi-Kashani M (2018) Actuation behavior of PDMS dielectric elastomer composites containing optimized graphene oxide. Smart Mater Struct 27(8):085021

Scaffaro R, Maio A (2019) Optimization of two-step techniques engineered for the preparation of polyamide 6 graphene oxide nanocomposites. Compos B Eng 165:55–64

Scaffaro R, Maio A (2019) Influence of oxidation level of graphene oxide on the mechanical performance and photo-oxidation resistance of a polyamide 6. Polymers 11(5):857

Hidayah, N., et al. (2017) Comparison on graphite, graphene oxide and reduced graphene oxide: Synthesis and characterization. In AIP Conference Proceedings. AIP Publishing LLC

Cui P et al (2011) One-pot reduction of graphene oxide at subzero temperatures. Chem Commun 47(45):12370–12372

Abbate F, dos Santos G, Iulianelli CV, Tavares MIB (2017) Development and properties evaluation of bio-based PLA/PLGA blend films reinforced with microcrystalline cellulose and organophilic silica. Polym Eng Sci 57(4):464–472

Moon IK et al (2010) Reduced graphene oxide by chemical graphitization. Nat Commun 1(1):1–6

Azizl MJ et al (2021) Graphene oxide and graphene hybrid nanocomposites based on compatibilized PP/PTW/EVA: effect of nanofiller and compatibilizer on the modeling of viscoplastic behavior. J Polym Res 28(8):293

Azizli MJ et al (2018) Studying the roles of nanoclay and blend composition on the improved properties of natural rubber/chloroprene composites. Polym Compos 39(5):1562–1574

Ebadi-Dehaghani H et al (2015) Experimental and theoretical analyses of mechanical properties of PP/PLA/clay nanocomposites. Compos B Eng 69:133–144

Azizli MJ et al (2021) Enhancement of thermal, morphological, and mechanical properties of compatibilized based on PA6-enriched graphene oxide/EPDM-g-MA/CR: graphene oxide and EPDM-g-MA compatibilizer role. J Appl Polym Sci 138(9):49901

Azizli MJ et al (2020) Compatibility, mechanical and rheological properties of hybrid rubber NR/EPDM-g-MA/EPDM/graphene oxide nanocomposites: theoretical and experimental analyses. Compos Commun 22:100442

Scaffaro R, Maio A (2019) Integrated ternary bionanocomposites with superior mechanical performance via the synergistic role of graphene and plasma treated carbon nanotubes. Compos B Eng 168:550–559

Gao Y et al (2017) Influence of filler size on the properties of poly (lactic acid)(PLA)/graphene nanoplatelet (GNP) nanocomposites. Eur Polymer J 86:117–131

Basu D et al (2016) Fire-safe and environmentally friendly nanocomposites based on layered double hydroxides and ethylene propylene diene elastomer. RSC Adv 6(31):26425–26436

Azizli MJ et al (2014) Improvement in physical and mechanical properties of iir/cr rubber blend organoclay nanocomposites. Rubber Chem Technol 87(1):10–20

Bijarimi M et al (2019) Preparation and characterization of poly (lactic acid) (PLA)/polyamide 6 (PA6)/graphene nanoplatelet (GNP) blends bio-based nanocomposites. Mater Res Express 6(5):055044

Scaffaro R, Maio A (2017) A green method to prepare nanosilica modified graphene oxide to inhibit nanoparticles re-aggregation during melt processing. Chem Eng J 308:1034–1047

Maio A et al (2015) A novel approach to prevent graphene oxide re-aggregation during the melt compounding with polymers. Compos Sci Technol 119:131–137

Scaffaro R et al (2018) Advanced piezoresistive sensor achieved by amphiphilic nanointerfaces of graphene oxide and biodegradable polymer blends. Compos Sci Technol 156:166–176

Scaffaro R et al (2005) Formulation, characterization and optimization of the processing condition of blends of recycled polyethylene and ground tyre rubber: mechanical and rheological analysis. Polym Degrad Stab 90(2):281–287

Azizli MJ et al (2021) Theoretical and experimental analyses of rheological, compatibility and mechanical properties of PVMQ/XNBR-g GMA/XNBR/GO ternary hybrid nanocomposites. Iran Polym J 30(10):1001–1018

Acknowledgements

The Saze Paidar Elahie (Linkran Industrial Group) Company gratefully is acknowledged by the authors. The authors also thank Saze Paidar Elahie (Linkran Industrial Group), Consulting rubber Engineers CO for supporting this research.

Funding

No fundings were received.

Author information

Authors and Affiliations

Contributions

MJA: wrote the main manuscript and revised the manuscript AG: wrote the main manuscript and ran the chemical reactions EV: wrote the main manuscript, ran the mechanical studies and morphology investigations. KR: ran the chemical reactions. SP: ran the mechanical studies. MM: performed the chemical and analyzed the whole tests. ZJ: ran the chemical reactions MH: ran the chemical reactions RB-L: analyzed the mechanical and thermal tests AMA: analyzed the chemical and mechanical tests and reactions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azizli, M.J., Ghadami, A., Vafa, E. et al. Compatibilization of Immiscible PA6/PLA Nanocomposites Using Graphene Oxide and PTW Compatibilizer for High Thermal and Mechanical Applications. J Polym Environ 31, 4193–4209 (2023). https://doi.org/10.1007/s10924-023-02870-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02870-6