Abstract

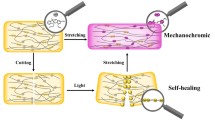

Regulation of the discoloration efficiency of mechanochromism materials is a big challenge to date. In this study, a series of polyurethane elastomers (PUEs) using dihydroxyspiropyran (SP2) as functional molecule with varied microstructure were synthesized. The mechanochromic behavior of PUEs and the relationship between it and the microstructure of PUEs was investigated. As a result, when SP2 was covalently bonded to PUE backbones, discoloration phenomenon was clearly detected and appears earlier in PUEs with higher microphase separation degree under stretching. On the other hand, the PUEs with ultralow microphase separation degree could hardly change color until the fracture of the materials. Therefore, the characteristic indigo blue appearance efficiency could be easily controlled (from 300 to 600% strain) by adjusting the microphase separation degree in these PUEs. The results will allow these materials to deal with broader stress range.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and the supplementary materials.

References

Cao ZQ (2020) Macromol Chem Phys 221(15):2000190. https://doi.org/10.1002/macp.202000190

Wang ZJ, Ma ZY (2015) Adv Mater 27(41):6469–6474. https://doi.org/10.1002/adma.201503424

Qiu WL, Gurr PA (2019) Polym Chem-Uk 10(13):1650–1659. https://doi.org/10.1039/C9PY00017H

Wang TS, Zhang N (2017) Acs Appl Mater Inter 9(13):11874–11881. https://doi.org/10.1021/acsami.7b00176

Kim TA, Beiermann BA (2016) Acs Macro Lett 5(12):1312–1316. https://doi.org/10.1021/acsmacrolett.6b00822

O’Bryan G, Wong BM (2010) Acs Appl Mater Inter 2(6):1594–1600. https://doi.org/10.1021/am100050v

Kingsbury CM, May PA (2011) J Mater Chem 21(23):8381–8388. https://doi.org/10.1039/C0JM04015K

Davis DA, Hamilton A (2009) Nature 459:68–72. https://doi.org/10.1038/nature07970

Hemmer JR, Smith PD (2014) J Polym Sci Pol Phys 52(20):1347–1356. https://doi.org/10.1002/polb.23569

Zhang FF, Ji R (2020) J Appl Polym Sci 137(42):49272. https://doi.org/10.1002/app.49272

Wang KP, Deng YP (2010) Polymer 210:123017. https://doi.org/10.1016/j.polymer.2020.123017

Dong HN, Wang YM (2022) J Polym Res 29(10):413. https://doi.org/10.1007/s10965-022-03271-4

Zhang H, Chen YJ (2014) Macromolecules 47(19):6783–6790. https://doi.org/10.1021/ma500760p

Fang XL, Zhang H (2013) Macromolecules 46(16):6566–6574. https://doi.org/10.1021/ma4014862

Lee CK, Beiermann BA (2013) Macromolecules 46(10):3746–3752. https://doi.org/10.1021/ma4005428

Kojio K, Nozaki S (2020) J Polym Res 27(6):140. https://doi.org/10.1007/s10965-020-02090-9

Akram N, Saleem S (2021) J Polym Res 28(7):238. https://doi.org/10.1007/s10965-021-02566-2

Seshimo K, Sakai H (2021) Angew Chem Int Ed 60(15):8406–8409. https://doi.org/10.1002/anie.202015196

Banan A, Mehdipour H (2021) J Polym Res 28(9):133. https://doi.org/10.1007/s10965-021-02671-2

Lin CL, Lin WL (2023) J Polym Res 30(2):54. https://doi.org/10.1007/s10965-022-03408-5

Baek SH, Kim JH (2021) Polym Test 103:107366. https://doi.org/10.1016/j.polymertesting.2021.107366

Zhang HT, Zhang F (2020) Ind Eng Chem Res 59(10):4483–4492. https://doi.org/10.1021/acs.iecr.9b06107

Pu MY, Zhou X (2023) Waste Manag 155:137–145. https://doi.org/10.1016/j.wasman.2022.10.032

Oprea S, Potolinca VO (2022) J Polym Res 29(9):369. https://doi.org/10.1007/s10965-022-03230-z

Cui YY, Pan HW (2022) J Polym Res 29(6):218. https://doi.org/10.1007/s10965-022-03079-2

Manuel B, Itzel G (2022) Chemosphere 307(P4):136136. https://doi.org/10.1016/j.chemosphere.2022.136136

Karaköse A, Hazer O (2022) J Polym Res 29(12):504. https://doi.org/10.1007/s10965-022-03345-3

Jung YS, Woo J (2022) J Polym Res 29(12):521. https://doi.org/10.1007/s10965-022-03375-x

Oprea S, Potolinca VO (2020) J Polym Res 27(3):60. https://doi.org/10.1007/s10965-020-2036-6

Yilgor I, Yilgor E (2007) Polym Rev 47(4):487–510. https://doi.org/10.1080/15583720701638260

Ji FL, Hu JL (2011) J Macromol Sci Phys 50(12):2290–2306. https://doi.org/10.1080/00222348.2011.562091

Chen KS, Yu TL (2001) J Polym Res 8(2):99–109. https://doi.org/10.1007/s10965-006-0139-3

Wang XY, Xu J (2022) Adv Mater 34(45):e2205763. https://doi.org/10.1002/adma.202205763

Candau N, Stoclet G (2021) Polymer 223:123708. https://doi.org/10.1016/j.polymer.2021.123708

Guo XW, Wang JX (2023) Chem Eng J 465:143074. https://doi.org/10.1016/j.cej.2023.143074

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (no.52103013 and no.52173208) and Funding of Jiangsu Educational Committee (19KJB430042).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Y., Huang, X., Wang, Z. et al. Regulation and control of discoloration efficiency of mechanochromic polyurethane elastomers by microstructure design. J Polym Res 30, 214 (2023). https://doi.org/10.1007/s10965-023-03607-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03607-8