Abstract

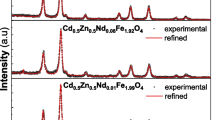

The report attempts to study some spinel such as cobalt (Co–F), nickel (Ni–F), copper (Cu–F) and magnesium (Mg–F) nanoferrites, which are synthesized by coprecipitation route and annealed at 850 °C for 2 h. Powder X-ray diffraction patterns depict the formation of single cubic spinel structure (Fd-3m). Thereby, lattice parameter is ranging between 8.3420 and 8.4009 Å, while average crystallite size is found in 20–38 nm. Transmission electron and scanning electron microscopies exhibit that the nanoparticles are agglomerated and revealing mixture of spherical and irregular shapes. The fit of Co–F, Ni–F and Cu–F room 57Fe Mössbauer spectra was established with two sextets, which reflects that the Fe3+ is occupied two sub-lattices of spinel system. A weak percentage of quadruple doublet, 2%, was observed in both Ni–F and Cu–F spectra. Exceptionally, the Mg–F room 57Fe Mössbauer spectrum indicates broadening lines due to disordering of iron magnetic moments because of small nanoparticle size (20 nm), it was fitted with hyperfine field distribution, Mg–F spectrum was also collected at 6 K reflecting a ferrimagnetic ordering according to Néel’s theory. M(T) curves indicate that the blocking temperature is higher than 300 K, except the Mg–F sample shows a TB of ~226 K. Besides, the M(H) loops at 5 K exhibit a soft behavior and the magnetic parameters like Ms, Mr, µe, Mr/Ms ration, Hc and Ka have determined for the studied spinel ferrites.

Similar content being viewed by others

Data availability

The datasets reported and analyzed during the present work are available from the corresponding author.

References

D.H.K. Reddy, Y.S. Yun, Coord. Chem. Rev. 315, 90 (2016). https://doi.org/10.1016/j.ccr.2016.01.012

A. Nigam, S.J. Pawar, Ceram. Int. 46, 4058 (2020). https://doi.org/10.1016/j.ceramint.2019.10.243

M. Amiri, M. Salavati-Niasari, A. Akbari, Adv. Colloid Interface Sci. 265, 29 (2019). https://doi.org/10.1016/j.cis.2019.01.003

N. Alghamdi, J. Stroud, M. Przybylski, J. Żukrowski, A.C. Hernandez, J.M. Brown, J.H. Hankiewicz, Z. Celinski, J. Magn. Magn. Mater. 497, 165981 (2019). https://doi.org/10.1016/j.jmmm.2019.165981

A. Manohar, D.D. Geleta, C. Krishnamoorthi, J. Lee, Ceram. Int. 46, 28035 (2020). https://doi.org/10.1016/j.ceramint.2020.07.298

S.R. Patade, D.D. Andhare, S.B. Somvanshi, S.A. Jadhav, M.V. Khedkar, K.M. Jadhav, Ceram. Int. 46, 1 (2020). https://doi.org/10.1016/j.ceramint.2020.07.029

B. Abraime, K. El-Maalam, L. Fkhar, A. Mahmoud, F. Boschini, M. Ait-Tamerd, A. Benyoussef, M. Hamedoun, E.K. Hlil, M. Ait-Ali, A. El-Kenz, O. Mounkachi, J. Magn. Magn. Mater. 500, 166416 (2019). https://doi.org/10.1016/j.jmmm.2020.166416

I.C. Sathisha, K. Manjunatha, A. Bajorek, B.R. Babu, B. Chethan, T.R.K. Reddy, Y.T. Ravikiran, V.J. Angadi, J. Alloys Compd. 848, 156577 (2020). https://doi.org/10.1016/j.jallcom.2020.156577

T.N. Pham, T.Q. Huy, A.T. Le, RSC Adv. 10, 31622 (2020). https://doi.org/10.1039/d0ra05133k

M. Kamran, M.A. Ur-Rehman, J. Alloys Compd. 822, 153583 (2020). https://doi.org/10.1016/j.jallcom.2019.153583

Z. Cvejić, E. Đurđić, G.I. Ivandekić, B. Bajac, P. Postolache, L. Mitoseriu, V.V. Srdić, S. Rakić, J. Alloys Compd. 649, 1231 (2015). https://doi.org/10.1016/j.jallcom.2015.07.238

A. Hussain, T. Abbas, S.B. Niazi, Ceram. Int. 39, 1221 (2013). https://doi.org/10.1016/j.ceramint.2012.07.049

C. Liu, B. Zou, A.J. Rondinone, Z.J. Zhang, J. Am. Chem. Soc. 122, 6263 (2000). https://doi.org/10.1021/ja000784g

Y. Qu, H. Yang, N. Yang, Y. Fan, H. Zhu, G. Zou, Mater. Lett. 60, 3548 (2006). https://doi.org/10.1016/j.matlet.2006.03.055

Q. Song, Z.J. Zhang, J. Am. Chem. Soc. 126, 6164 (2004). https://doi.org/10.1021/ja049931r

M.A. Cobos, P. de la Presa, I. Llorente, A. García-Escorial, A. Hernando, J.A. Jiménez, J. Alloys Compd. 849, 156353 (2020). https://doi.org/10.1016/j.jallcom.2020.156353

M. Ounacer, M. Sajieddine, A. Essoumhi, in Proceeding in IEEE 6th International Conference on Optimization and Applications, (2020), p. 1. https://doi.org/10.1109/ICOA49421.2020.9094518

C.N. Anumol, M. Chithra, M. Govindaraj Shalini, S.C. Sahoo, Effect of annealing on structural and magnetic properties of NiFe2O4/ZnFe2O4 nanocomposites. J. Magn. Magn. Mater. 469, 81 (2019)

M. Ounacer, B. Rabi, A. Essoumhi, M. Sajieddine, B.F.O. Costa, M. Emo, A. Razouk, M. Sahlaoui, J. Alloys Compd. 854, 156968 (2020). https://doi.org/10.1016/j.jallcom.2020.156968

M.M. Althubayti, M. Hjiri, N.H. Alonizan, O.M. Lemine, M.S. Aida, J. Mater. Sci. Mater. Electron. 31, 8194 (2020). https://doi.org/10.1007/s10854-020-03354-2

F. Moravvej-Farshi, M. Amishi, K.A. Nekouee, J. Mater. Sci. Mater. Electron. 31, 13610 (2020). https://doi.org/10.1007/s10854-020-03917-3

S. Packiaraj, M. Jeyaraj, K. Chandarasekaran, J.M. Rawson, S. Govindarajan, J. Mater. Sci. Mater. Electron. 30, 18866 (2019). https://doi.org/10.1007/s10854-019-02243-7

A. Omri, E. Dhahri, B.F.O. Costa, M.A. Valente, J. Magn. Magn. Mater. 499, 166243 (2020). https://doi.org/10.1016/j.jmmm.2019.166243

S.H. Yu, Q.L. Wang, Y. Chen, Y. Wang, J.H. Wang, Mater. Lett. 278, 128431 (2020). https://doi.org/10.1016/j.matlet.2020.128431

X. Zhang, Z. Chen, C. Wu, J. Zhang, F. Wang, Chem. Phys. Lett. 732, 136647 (2019). https://doi.org/10.1016/j.cplett.2019.136647

M. Ounacer, A. Essoumhi, M. Sajieddine, A. Razouk, B.F.O. Costa, S.M. Dubiel, M. Sahlaoui, J. Supercond. Nov. Magn. 33, 3249 (2020). https://doi.org/10.1007/s10948-020-05586-z

R.A. Brand, NORMOS Programs, Internal Report, in Angewandte Physik, Universität Duisburg, 1987.

D.D. Andhare, S.R. Patade, J.S. Kounsalye, K.M. Jadhav, Phys. B Condens. Matter 583, 412051 (2020). https://doi.org/10.1016/j.physb.2020.412051

M. Ounacer, A. Essoumhi, M. Sajieddine, A. Razouk, A. Fnidiki, F. Richomme, J. Juraszek, S.M. Dubiel, M. Sahlaoui, J. Phys. Chem. Solids 148, 109687 (2021). https://doi.org/10.1016/j.jpcs.2020.109687

R.D. Shannon, Acta Crystallogr. Sect. A 32, 751 (1976)

J. Jacob, M. Abdul-Khadar, J. Magn. Magn. Mater. 322, 614 (2010). https://doi.org/10.1016/j.jmmm.2009.10.025

D. Peddis, N. Yaacoub, M. Ferretti, A. Martinelli, G. Piccaluga, A. Musinu, C. Cannas, G. Navarra, J.M. Greneche, D. Fiorani, J. Phys. Condens. Matter 23, 426004 (2011). https://doi.org/10.1088/0953-8984/23/42/426004

L. Ajroudi, N. Mliki, L. Bessais, V. Madigou, S. Villain, C. Leroux, Mater. Res. Bull. 59, 49 (2014). https://doi.org/10.1016/j.materresbull.2014.06.029

J. Sanchez-Marcos, E. Mazario, J.A. Rodriguez-Velamazan, E. Salas, P. Herrasti, N. Menendez, J. Alloys Compd. 739, 909 (2018). https://doi.org/10.1016/j.jallcom.2017.12.342

E.V. Gopalan, I.A. Al-Omari, D.S. Kumar, Y. Yoshida, P.A. Joy, M.R. Anantharaman, Appl. Phys. A 99, 497 (2010). https://doi.org/10.1007/s00339-010-5573-8

L. Kumar, P. Kumar, S.K. Srivastava, M. Kar, J. Supercond. Nov. Magn. 27, 1677 (2014). https://doi.org/10.1007/s10948-014-2519-y

S. Joshi, M. Kumar, S. Chhoker, G. Srivastava, M. Jewariya, V.N. Singh, J. Mol. Struct. 1076, 55 (2014). https://doi.org/10.1016/j.molstruc.2014.07.048

M.A. Almessiere, Y. Slimani, M. Sertkol, M. Nawaz, A. Sadaqat, A. Baykal, I. Ercan, B. Ozçelik, Nanomaterials 9, 1 (2019). https://doi.org/10.3390/nano9030430

S.F. Mansour, O.M. Hemeda, S.I. El-dek, B.I. Salem, J. Magn. Magn. Mater. 420, 7 (2016). https://doi.org/10.1016/j.jmmm.2016.06.082

S.T. Alone, S.E. Shirsath, R.H. Kadam, K.M. Jadhav, J. Alloys Compd. 509, 5055 (2011). https://doi.org/10.1016/j.jallcom.2011.02.006

R.S. Yadav, J. Havlica, J. Masilko, L. Kalina, J. Wasserbauer, M. Hajdúchová, V. Enev, I. Kuřitka, Z. Kožáková, J. Magn. Magn. Mater. 399, 109 (2016). https://doi.org/10.1016/j.jmmm.2015.09.055

H. Taati, O. Mirzaee, H. Koohestani, J. Alloys Compd. 822, 153635 (2020). https://doi.org/10.1016/j.jallcom.2019.153635

P. Thandapani, M.R. Viswanathan, M. Vinícius-Araújo, A.F. Bakuzis, F. Béron, A. Thirumurugan, J.C. Denardin, J.A. Jiménez, A. Akbari-Fakhrabadi, J. Am. Ceram. Soc. 103, 5086 (2020). https://doi.org/10.1111/jace.17175

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

MO synthesized MeFe2O4 samples, carried out the experiment, analyzed the data, calculated the Mössbauer spectra, designed the figures and drafted the manuscript; AE contributed to sample preparation and to the final version of the manuscript; BR contributed to sample preparation and to the final version of the manuscript; EA carried out the experiment and contributed to the interpretation of the results; AE established the thermal analysis, TG–DTA, of as-prepared samples and contributed to the interpretation of the results; BFOC carried out the VSM measurements at low temperature and SEM observations; SMD characterized the MgFe2O4 with 57Fe Mössbauer spectroscopy at 6 K; AF, FR and JJ performed the SQUID measurements at low temperature; MS supervised the findings of this work and provided critical feedback and helped shape of the research; All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists.

Research involving human and animal rights

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ounacer, M., El Boubekri, A., Rabi, B. et al. Structural and magnetic studies of coprecipitated Me-spinel (Me = Co, Ni, Cu and Mg) ferrite nanoparticles. J Mater Sci: Mater Electron 33, 16655–16668 (2022). https://doi.org/10.1007/s10854-022-08562-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08562-6