Abstract

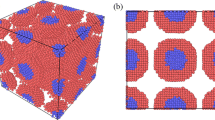

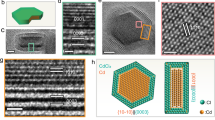

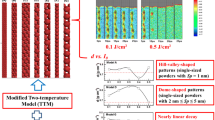

Understanding the mechanisms behind sintering Cu-Ag core–shell nanoparticles can help us optimize the sintering process parameters and design the core–shell structure to achieve the desired sintering structure. In this paper, we employed molecular dynamics simulations to investigate the sintering behaviors and mechanisms of CS NPs, taking into account the effects of shell thickness, particle size, and temperature. Our results revealed that dislocation loops in Cu-Ag CS NPs played a crucial role in sintering by emitting dislocations that facilitated crystal evolution, thereby reducing the number of amorphous structures. The state of dislocation loops could be controlled by shell thickness and NP size. As the shell thickness decreased to 0.5 nm, the structure of the dislocation loops could not be generated due to the extremely chaotic and thin Ag atoms. Furthermore, for NPs of the same size, the CS NP with a 0.5-nm shell thickness was the most active. Despite the neck not consisting of a Cu core, the Cu core, particularly its interface, could still participate in the sintering process. At 900 K, limited interface diffusion could be activated.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Buffat P, Borel J-P (1976) Size effect on the melting temperature of gold particles. Phys Rev A 13:2287–2298. https://doi.org/10.1103/PhysRevA.13.2287

Zhong Y, An R, Wang C, Zheng Z, Liu ZQ, Liu CH, Li CF, Kim TK, Jin S (2015) Low temperature sintering Cu6Sn5 nanoparticles for superplastic and super-uniform high temperature circuit interconnections. Small 11:4097–4103. https://doi.org/10.1002/smll.201500896

Alarifi HA, Atis M, Özdoǧan C, Hu A, Yavuz M, Zhou Y (2013) Molecular dynamics simulation of sintering and surface premelting of silver nanoparticles. Mater Trans 54:884–889. https://doi.org/10.2320/matertrans.MD201225

Liu Y, Li Z, Zhang H, Sun F (2019) Microstructure and mechanical properties of nano-Ag sintered joint enhanced by Cu foam. J Mater Sci Mater Electron 30:15795–15801. https://doi.org/10.1007/s10854-019-01965-y

Xu L, Wang Y-Y, Huang J, Chen C-Y, Wang Z-X, Xie H (2020) Silver nanoparticles: synthesis, medical applications and biosafety. Theranostics 10:8996–9031. https://doi.org/10.7150/thno.45413

Hai HT, Takamura H, Koike J (2013) Oxidation behavior of Cu-Ag core-shell particles for solar cell applications. J Alloy Compd 564:71–77. https://doi.org/10.1016/j.jallcom.2013.02.048

Yang C, Wong CP, Yuen MMF (2013) Printed electrically conductive composites: conductive filler designs and surface engineering. J Mater Chem C 1:4052–4069. https://doi.org/10.1039/c3tc00572k

Jiang Z, Tian Y, Ding S (2014) Synthesis and characterization of ultra-long and pencil-like copper nanowires with a penta-twinned structure by hydrothermal method. Mater Lett 136:310–313. https://doi.org/10.1016/j.matlet.2014.08.033

Lee C, Kim NR, Koo J, Lee YJ, Lee HM (2015) Cu-Ag core–shell nanoparticles with enhanced oxidation stability for printed electronics. Nanotechnology 26:455601. https://doi.org/10.1088/0957-4484/26/45/455601

Cheng B, Ngan AHW (2013) The crystal structures of sintered copper nanoparticles: a molecular dynamics study. Int J Plast 47:65–79. https://doi.org/10.1016/j.ijplas.2013.01.006

Liu L, Shi R, Zhang S, Liu W, Huang S, Chen Z (2023) Effects of Ag shell on electrical, thermal and mechanical properties of Cu@Ag composite solder preforms by electromagnetic compaction for power electronics. Mater Charact 197:112702. https://doi.org/10.1016/j.matchar.2023.112702

Yang G, Luo S, Lai T, Lai H, Luo B, Li Z, Zhang Y, Cui C (2022) A Green and facile Microvia filling method via printing and sintering of Cu-Ag core-shell nano-microparticles. Nanomaterials 12:1063. https://doi.org/10.3390/nano12071063

Raut JS, Bhagat RB, Fichthorn KA (1998) Sintering of aluminum nanoparticles: a molecular dynamics study. Nanostruct Mater 10:837–851. https://doi.org/10.1016/S0965-9773(98)00120-2

Guo JY, Xu CX, Hu AM, Oakes KD, Sheng FY, Shi ZL, Dai J, Jin ZL (2012) Sintering dynamics and thermal stability of novel configurations of Ag clusters. J Phys Chem Solids 73:1350–1357. https://doi.org/10.1016/j.jpcs.2012.06.010

Buesser B, Gröhn AJ, Pratsinis SE (2011) Sintering rate and mechanism of TiO2 nanoparticles by molecular dynamics. J Phys Chem C 115:11030–11035. https://doi.org/10.1021/jp2032302

Yang L, Gan Y, Zhang Y, Chen JK (2012) Molecular dynamics simulation of neck growth in laser sintering of different-sized gold nanoparticles under different heating rates. Appl Phys A 106:725–735. https://doi.org/10.1007/s00339-011-6680-x

Grammatikopoulos P, Cassidy C, Singh V, Benelmekki M, Sowwan M (2014) Coalescence behaviour of amorphous and crystalline tantalum nanoparticles: a molecular dynamics study. J Mater Sci 49:3890–3897. https://doi.org/10.1007/s10853-013-7893-5

Cheng B, Ngan AHW (2013) The sintering and densification behaviour of many copper nanoparticles: a molecular dynamics study. Comput Mater Sci 74:1–11. https://doi.org/10.1016/j.commatsci.2013.03.014

Ding L, Davidchack RL, Pan J (2009) A molecular dynamics study of sintering between nanoparticles. Comput Mater Sci 45:247–256. https://doi.org/10.1016/j.commatsci.2008.09.021

Wang J, Shin S, Hu A (2016) Geometrical effects on sintering dynamics of Cu-Ag core-shell nanoparticles. J Phys Chem C 120:17791–17800. https://doi.org/10.1021/acs.jpcc.6b05515

Mortazavi B, Silani M, Podryabinkin EV, Rabczuk T, Zhuang X, Shapeev AV (2021) First-principles multiscale modeling of mechanical properties in graphene/borophene heterostructures empowered by machine-learning interatomic potentials. Adv Mater 33:2102807. https://doi.org/10.1002/adma.202102807

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Model Simul Mater Sci Eng 20:085007. https://doi.org/10.1088/0965-0393/20/8/085007

Daw MS, Baskes MI (1984) Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B 29:6443–6453. https://doi.org/10.1103/PhysRevB.29.6443

Williams PL, Mishin Y, Hamilton JC (2006) An embedded-atom potential for the Cu-Ag system. Model Simul Mater Sci Eng 14:817–833. https://doi.org/10.1088/0965-0393/14/5/002

Plimpton S (2009) Fast parallel algorithms for short- range molecular dynamics. Model Simul Mater Sci Eng 18:44. https://doi.org/10.1006/jcph.1995.1039

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Model Simul Mater Sci Eng 18:015012. https://doi.org/10.1088/0965-0393/18/1/015012

Li Q, Wang M, Liang Y, Lin L, Fu T, Wei P, Peng T (2017) Molecular dynamics simulations of aggregation of copper nanoparticles with different heating rates. Phys E 90:137–142. https://doi.org/10.1016/j.physe.2017.03.024

Lange AP, Samanta A, Majidi H, Mahajan S, Ging J, Olson TY, van Benthem K, Elhadj S (2016) Dislocation mediated alignment during metal nanoparticle coalescence. Acta Mater 120:364–378. https://doi.org/10.1016/j.actamat.2016.08.061

Raether F, Seifert G, Ziebold H (2019) Simulation of sintering across scales. Adv Theory Simul 2:1900048. https://doi.org/10.1002/adts.201900048

Zhan L, Zhu X, Qin X, Wu M, Li X (2021) Sintering mechanism of copper nanoparticle sphere-plate of crystal misalignment: a study by molecular dynamics simulations. J Mater Res Technol 12:668–678. https://doi.org/10.1016/j.jmrt.2021.03.029

Wang J, Shin S (2017) Sintering of multiple Cu-Ag core-shell nanoparticles and properties of nanoparticle-sintered structures. RSC Adv 7:21607–21617. https://doi.org/10.1039/c7ra02611k

Lechner W, Dellago C (2008) Accurate determination of crystal structures based on averaged local bond order parameters. J Chem Phys. https://doi.org/10.1063/1.2977970

Zhang W, Zhou Y, Ding Y, Song L, Yuan Q, Zhao W, Xu C, Wei J, Li M, Ji H (2022) Sintering mechanism of size-controllable Cu-Ag core–shell nanoparticles for flexible conductive film with high conductivity, antioxidation, and electrochemical migration resistance. Appl Surf Sci 586:152691. https://doi.org/10.1016/j.apsusc.2022.152691

Wang W, Hua D, Zhou Q, Li S, Eder SJ, Shi J, Wang Z, Wang H, Liu W (2023) Effect of a water film on the material removal behavior of Invar during chemical mechanical polishing. Appl Surf Sci 616:156490. https://doi.org/10.1016/j.apsusc.2023.156490

Li S, Liu Y, Sun F, Fang H (2021) Multi-particle molecular dynamics simulation: shell thickness effects on sintering process of Cu-Ag core-shell nanoparticles. J Nanopart Res 23:6. https://doi.org/10.1007/s11051-021-05144-1

Talebi H, Silani M, Bordas SPA, Kerfriden P, Rabczuk T (2014) A computational library for multiscale modeling of material failure. Comput Mech 53:1047–1071. https://doi.org/10.1007/s00466-013-0948-2

Acknowledgements

This work was supported by the Key Research and Development Program of Heilongjiang (GZ20210086), National Natural Science Foundation of China (51174069) and the Shenzhen Fundamental Research Program (JCYJ20200109140822796).

Funding

The Key Research and Development Program of Heilongjiang, GZ20210086, Yang Liu, National Natural Science Foundation of China, 51174069, Yang Liu, Shenzhen Fundamental Research Program, JCYJ20200109140822796.

Author information

Authors and Affiliations

Contributions

ZZ carried out simulation and manuscript composition. SL done simulation design and carrying out simulation. YL did conception and resources.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Ethical approval for this study was granted by ethics committee of Harbin University of Science and Technology as no human tissue was used in the experiments. The study was conducted in accordance with the ethical principles outlined in ethics committee of Harbin University of Science and Technology.

Additional information

Handling Editor: Ghanshyam Pilania.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Z., Li, S. & Liu, Y. Insight into the shell-dependent sintering behavior of Cu-Ag core–shell nanoparticle from molecular dynamics simulation. J Mater Sci 58, 13059–13079 (2023). https://doi.org/10.1007/s10853-023-08763-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08763-2