Abstract

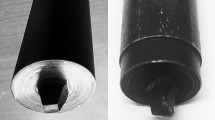

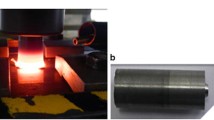

Friction stir spot welding on Al 6061-T6 aluminium alloy was performed to examine the influence of parameters, e.g. tool pin profile, shoulder plunge depth, diameter of shoulder and SiC particles on mechanical properties, macro-structural and micro-structural properties of welds. During the detailed experimentation the behaviour of hook formation, stir zone width, bonded region width and tensile-shear strength was scientifically measured, studied and discussed. Distribution of SiC particles was analysed as it affected the weld quality. Homogeneous distribution of SiC particles helped in entrapping the dislocations during tensile-shear loading of welds. A stronger weld was witnessed with the increase in diameter of the tool shoulder, while there was an increase and then a sudden decrease in weld strength with increase in shoulder plunge depth. Square tool pin was identified as optimum tool pin profile for obtaining stronger welds. The reduction in hook formation was observed with increased shoulder diameter and shoulder plunge depth. Square tool pin increased the material flow and reduced hook length by pushing it away from key hole due to increased stir zone width. SiC particles were observed to be homogeneously distributed with square tool pin profile, greater diameter of tool shoulder and optimum shoulder plunge depth.

Similar content being viewed by others

References

Tanaka T, Nezu M, Uchida S, Hirata T (2020) Mechanism of intermetallic compound formation during the dissimilar friction stir welding of aluminum and steel. J Mater Sci 55(7):3064–3072. https://doi.org/10.1007/s10853-019-04106-2

Chaudhary N, Singh S (2022) Experimental investigation and ANFIS-based modelling of effect of process parameters on friction stir spot welding of Al 6061-T6. 1–11

Mazzaferro CCP, Rosendo TS, Tier MAD, Mazzaferro JAE, Dos Santos JF, Strohaecker TR (2015) Microstructural and mechanical observations of galvanized TRIP steel after friction stir spot welding. Mater Manuf Process 30(9):1090–1103

UTZEL E (2009) Advantages and disadvantages of arc and laser welding. Hybrid laser-arc welding, 1

Chaudhary N, Singh S, Garg MP, Garg HK, Sharma S, Li C, El-Khatib S (2022) Parametric optimisation of friction-stir-spot-welded Al 6061-T6 incorporated with silicon carbide using a hybrid WASPAS–Taguchi technique. Materials 15(18):6427

Chaudhary N, Singh S (2022) Development of in situ MMC joint using friction stir spot welding of Al6061-T6. Int J Adv Manuf Technol 123:3633–3646

Sadeghi B, Abbasi H, Atapour M, Shafiee S, Cavaliere P, Marfavi Z (2020) Friction stir spot welding of TiO2 nanoparticle-reinforced interstitial free steel. J Mater Sci 55(26):12458–12475. https://doi.org/10.1007/s10853-020-04838-6

Singh S, Satsangi, PS (2021) A review on friction stir spot welding of similar and dissimilar materials. Lect. Notes Mech. Eng. 531–541. https://doi.org/10.1007/978-981-33-4018-3_50/COVER

Ramya G, Pounrajan S, Prasad DVSSSV, Soni S, Ravichandran P, Kosanam K, Amara SALG, Gupta G, Dinesh PM, Kumar L, Shaik B (2022) Assessment of rotational speed and plunge rate on lap shear strength of FSSW joints of AA7075/mild steel. Adv Mater Sci Eng 2022:9. https://doi.org/10.1155/2022/6215249

Garg M, Grewal HS, Sharma RK, Arora HS (2022) Enhanced oxidation resistance of ultrafine-grain microstructure AlCoCrFeNi high entropy alloy. ACS Omega 7(15):12589–12600

Garg M, Grewal HS, Sharma RK, Gwalani B, Arora HS (2022) High oxidation resistance of AlCoCrFeNi high entropy alloy through severe shear deformation processing. J Alloys Compd 165385. https://doi.org/10.1016/j.jallcom.2022.165385

Elangovan K, Balasubramanian V (2008) Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater Des 29(2):362–373

Garg A, Bhattacharya A (2017) On lap shear strength of friction stir spot welded AA6061 alloy. J Manuf Process 26:203–215

Lin YC, Liu JJ, Lin BY (2012) Effect of tool geometry on strength of friction stir spot welded aluminum alloys. In Advanced materials research (Vol. 579, pp. 109–117). Trans Tech Publications Ltd

Jain R, Pal SK, Singh SB (2019) Investigation on effect of pin shapes on temperature, material flow and forces during friction stir welding: a simulation study. Proc Inst Mech Eng Part B J Eng Manuf 233(9):1980–1992

Badarinarayan H, Shi Y, Li X, Okamoto K (2009) Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets. Int J Mach Tools Manuf 49(11):814–823

Ramanjaneyulu K, Reddy GM, Rao AV, Markandeya R (2013) Structure-property correlation of AA2014 friction stir welds: role of tool pin profile. J Mater Eng Perform 22(8):2224–2240

Lambiase F, Paoletti A, Di Ilio A (2016) Effect of tool geometry on loads developing in friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 87(5):2293–2303

Padmanaban R, Vignesh RV, Arivarasu M, Karthick KP, Sundar AA (2016) Process parameters effect on the strength of friction stir spot-welded AA6061. ARPN J Eng Appl Sci 11(9):6030–6035

Bozzi S, Helbert-Etter AL, Baudin T, Klosek V, Kerbiguet JG, Criqui B (2010) Influence of FSSW parameters on fracture mechanisms of 5182 aluminium welds. J Mater Process Technol 210(11):1429–1435

Marzbanrad J, Akbari M, Asadi P, Safaee S (2014) Characterization of the influence of tool pin profile on microstructural and mechanical properties of friction stir welding. Metall Mater Trans B 45(5):1887–1894

Ashu GARG, Raturi M, Bhattacharya A (2019) Metallurgical behavior and variation of vibro-acoustic signal during preheating assisted friction stir welding between AA6061-T6 and AA7075-T651 alloys. Trans Nonferrous Met Soc China 29(8):1610–1620

Badarinarayan H, Yang Q, Zhu S (2009) Effect of tool geometry on static strength of friction stir spot-welded aluminum alloy. Int J Mach Tools Manuf 49(2):142–148

Yang Q, Mironov S, Sato YS, Okamoto K (2010) Material flow during friction stir spot welding. Mater Sci Eng A 527(16–17):4389–4398

Mugada KK, Adepu K (2021) Role of scroll shoulder and pin designs on axial force, material flow and mechanical properties of friction stir welded Al–Mg–Si alloy. Met Mater Int 27(8):2809–2820

Fujimoto M, Koga S, Abe N, Sato SY, Kokawa H (2008) Analysis of plastic flow of the Al alloy joint produced by friction stir spot welding. Yosetsu Gakkai Ronbunshu/Q J Japan Weld Soc 26(1):67–73

Rao HM, Jordon JB, Barkey ME, Guo YB, Su X, Badarinarayan H (2013) Influence of structural integrity on fatigue behavior of friction stir spot welded AZ31 Mg alloy. Mater Sci Eng A 564:369–380

Babu S, Sankar VS, Janaki Ram GD, Venkitakrishnan PV, Madhusudhan Reddy G, Prasad Rao K (2013) Microstructures and mechanical properties of friction stir spot welded aluminum alloy AA2014. J Mater Eng Perform 22(1):71–84

Bilici MK, Yükler AI, Kurtulmuş M (2016) Pin profile and shoulder geometry effects in friction stir spot welded polymer sheets. Int J Eng Sci (IJES) 5(6):29–36

Kumar N, Mishra RS, Huskamp CS, Sankaran KK (2011) Microstructure and mechanical behavior of friction stir processed ultrafine grained Al–Mg–Sc alloy. Mater Sci Eng A 528(18):5883–5887

Arora KS, Pandey S, Schaper M, Kumar R (2010) Microstructure evolution during friction stir welding of aluminum alloy AA2219. J Mater Sci Technol 26(8):747–753

Upadhyay P, Reynolds A (2014) Effect of backing plate thermal property on friction stir welding of 25-mm-thick AA6061. Metall Mater Trans A 45(4):2091–2100

Ungár T (2001) Dislocation densities, arrangements and character from X-ray diffraction experiments. Mater Sci Eng A 309:14–22

Acknowledgements

The authors wish to acknowledge SIEMENS Centre of Excellence, Punjab Engineering College (Deemed to be University), Chandigarh for providing research facility.

Funding

The authors confirm that throughout the process of preparing this manuscript, they did not receive any funding, grants, or other support of any kind.

Author information

Authors and Affiliations

Contributions

The first draft of the manuscript was written by first author and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that they have no financial or non-financial interests to disclose.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaudhary, N., Singh, S. Experimental investigation on microstructural and mechanical properties of in situ SiC-reinforced friction stir spot weld of Al 6061-T6. J Mater Sci 58, 1849–1868 (2023). https://doi.org/10.1007/s10853-022-08110-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08110-x