Abstract

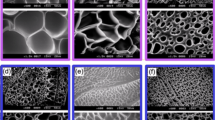

Dissolution of cellulose is a promising approach to control the rheology and processability of cellulose. However, dissolution of cellulose is extremely difficult because of the strong hydrogen bonding network, the hydrophobic interactions, and high crystallinity. In this study, partially dissolved cellulose composites (denoted as PDCC) with high cellulose content are prepared by inserting 1-butyl-3-methylimidazolium chloride (BmimCl) into cellulose fibrils through the repeated rolling method, and rheological properties of obtained PDCC with different cellulose content are fully characterized on the high-pressure capillary rheometer under different temperature. The viscosity of PDCC is 4 orders of magnitude higher than that of cellulose solutions prepared by full dissolution, and PDCC has obvious shear thinning behavior, similar to that of polymer melt (e.g., low-density polyethylene, denoted as LDPE). The rheological properties of PDCC are attributed to its peculiar morphological structure where non-dissolved cellulose in the core areas is glued by dissolved cellulose in the surface areas, according to scanning electronic microscope images and X-ray diffraction. The viscosities of PDCC could be significantly decreased by lowering cellulose content and increasing temperature. Moreover, the correlation coefficients analysis of processing parameters and flow behavior of PDCC, indicates that the cellulose content dominates the flow behavior of PDCC. Using the hot press as a model manufacturing method, PDCC was fabricated as boards with dimensions of 50 × 50 × 2 mm. This work paves a potential avenue for processing cellulose with high content.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Ahn Y, Kwak S-Y, Song Y, Kim H (2016) Physical state of cellulose in BmimCl: dependence of molar mass on viscoelasticity and sol–gel transition. Phys Chem Chem Phys 18:1460–1469. https://doi.org/10.1039/C5CP06616F

Alves L, Medronho B, Filipe A et al (2021) Revisiting the dissolution of cellulose in H3PO4(aq) through cryo-TEM, PTssNMR and DWS. Carbohydr Polym 252:117122. https://doi.org/10.1016/j.carbpol.2020.117122

Andanson J-M, Bordes E, Devémy J et al (2014) Understanding the role of co-solvents in the dissolution of cellulose in ionic liquids. Green Chem 16:2528. https://doi.org/10.1039/c3gc42244e

Bernal-García JM, Guzmán-López A, Cabrales-Torres A et al (2008) Densities and viscosities of (N,N-dimethylformamide + water) at atmospheric pressure from (283.15 to 353.15) K. J Chem Eng Data 53:1024–1027. https://doi.org/10.1021/je700671t

Bioni TA, de Oliveira ML, Dignani MT, El Seoud OA (2020) Understanding the efficiency of ionic liquids–DMSO as solvents for carbohydrates: use of solvatochromic- and related physicochemical properties. New J Chem 44:14906–14914. https://doi.org/10.1039/D0NJ02258F

Chen X, Zhang Y, Wang H et al (2011) Solution rheology of cellulose in 1-butyl-3-methyl imidazolium chloride. J Rheol 55:485–494. https://doi.org/10.1122/1.3553032

Chen Y-L, Zhang X, You T-T, Xu F (2019) Deep eutectic solvents (DESs) for cellulose dissolution: a mini-review. Cellulose 26:205–213. https://doi.org/10.1007/s10570-018-2130-7

Dias YJ, Kolbasov A, Sinha-Ray S et al (2020) Theoretical and experimental study of dissolution mechanism of cellulose. J Mol Liq. https://doi.org/10.1016/j.molliq.2020.113450

Feng L, Chen Z (2008) Research progress on dissolution and functional modification of cellulose in ionic liquids. J Mol Liq 142:1–5. https://doi.org/10.1016/j.molliq.2008.06.007

Förster S, Konrad M, Lindner P (2005) Shear thinning and orientational ordering of Wormlike micelles. Phys Rev Lett 94:017803. https://doi.org/10.1103/PhysRevLett.94.017803

Foster EJ, Moon RJ, Agarwal UP et al (2018) Current characterization methods for cellulose nanomaterials. Chem Soc Rev 47:2609–2679. https://doi.org/10.1039/C6CS00895J

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Gericke M, Schlufter K, Liebert T et al (2009) Rheological properties of cellulose/ionic liquid solutions: from dilute to concentrated states. Biomacromolecules 10:1188–1194. https://doi.org/10.1021/bm801430x

Ghasemi M, Singapati AY, Tsianou M, Alexandridis P (2017) Dissolution of semicrystalline polymer fibers: numerical modeling and parametric analysis. AIChE J 63:1368–1383. https://doi.org/10.1002/aic.15615

Gong J, Li J, Xu J et al (2017) Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Adv 7:33486–33493. https://doi.org/10.1039/C7RA06222B

Higgins HG, Stewart CM, Harrington KJ (1961) Infrared spectra of cellulose and related polysaccharides. J Polym Sci 51:59–84. https://doi.org/10.1002/pol.1961.1205115505

Jia C, Chen C, Kuang Y et al (2018) From wood to textiles: top-down assembly of aligned cellulose nanofibers. Adv Mater 30:1801347. https://doi.org/10.1002/adma.201801347

Jiang S, Zhang M, Li M et al (2020) Cellulose nanofibril (CNF) based aerogels prepared by a facile process and the investigation of thermal insulation performance. Cellulose 27:6217–6233. https://doi.org/10.1007/s10570-020-03224-4

Kondo T, Nojiri M, Hishikawa Y et al (2002) Biodirected epitaxial nanodeposition of polymers on oriented macromolecular templates. Proc Natl Acad Sci 99:14008–14013. https://doi.org/10.1073/pnas.212238399

Lee K-Y, Aitomäki Y, Berglund LA et al (2014) On the use of nanocellulose as reinforcement in polymer matrix composites. Compos Sci Technol 105:15–27. https://doi.org/10.1016/j.compscitech.2014.08.032

Li T, Chen C, Brozena AH et al (2021a) Developing fibrillated cellulose as a sustainable technological material. Nature 590:47–56. https://doi.org/10.1038/s41586-020-03167-7

Li Z, Chen C, Xie H et al (2021b) Sustainable high-strength macrofibres extracted from natural bamboo. Nat Sustain. https://doi.org/10.1038/s41893-021-00831-2

Li T, Song J, Zhao X et al (2018) Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci Adv 4:eaar3724. https://doi.org/10.1126/sciadv.aar3724

Lindman B, Medronho B, Alves L et al (2021) Hydrophobic interactions control the self-assembly of DNA and cellulose. Q Rev Biophys 54:e3. https://doi.org/10.1017/S0033583521000019

Lu F, Wang L, Zhang C et al (2015) Influence of temperature on the solution rheology of cellulose in 1-ethyl-3-methylimidazolium chloride/dimethyl sulfoxide. Cellulose 22:3077–3087. https://doi.org/10.1007/s10570-015-0740-x

Luo N, Lv Y, Wang D et al (2012) Direct visualization of solution morphology of cellulose in ionic liquids by conventional TEM at room temperature. Chem Commun 48:6283. https://doi.org/10.1039/c2cc31483e

Murphy T, Varela LM, Webber GB et al (2014) Nanostructure–thermal conductivity relationships in protic ionic liquids. J Phys Chem B 118:12017–12024. https://doi.org/10.1021/jp507408r

Nishino T, Arimoto N (2007) All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules 8:2712–2716. https://doi.org/10.1021/bm0703416

Nishino T, Peijs T (2013) All-cellulose composites. Handbook of Green materials. WORLD SCIENTIFIC, pp 201–216

Remsing RC, Swatloski RP, Rogers RD, Moyna G (2006) Mechanism of cellulose dissolution in the ionic liquid 1-n-butyl-3-methylimidazolium chloride: a 13 C and 35/37Cl NMR relaxation study on model systems. Chem Commun. https://doi.org/10.1039/b600586c

Sayyed AJ, Deshmukh NA, Pinjari DV (2019) A critical review of manufacturing processes used in regenerated cellulosic fibres: viscose, cellulose acetate, cuprammonium, LiCl/DMAc, ionic liquids, and NMMO based lyocell. Cellulose 26:2913–2940. https://doi.org/10.1007/s10570-019-02318-y

Schroeter J, Felix F (2005) Melting cellulose. Cellulose 12:159–165. https://doi.org/10.1007/s10570-004-0344-3

Šturcová A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 6:1055–1061. https://doi.org/10.1021/bm049291k

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ionic liquids. J Am Chem Soc 124:4974–4975. https://doi.org/10.1021/ja025790m

Tan X, Li X, Chen L, Xie F (2016) Solubility of starch and microcrystalline cellulose in 1-ethyl-3-methylimidazolium acetate ionic liquid and solution rheological properties. Phys Chem Chem Phys 18:27584–27593. https://doi.org/10.1039/C6CP04426C

Terinte N, Ibbett R, Schuster K (2011) Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): comparison between measurement techniques. Lenzing Berichte 89:118

Tu H, Zhu M, Duan B, Zhang L (2020) Recent progress in high-strength and robust regenerated cellulose materials. Adv Mater 2000682. doi: 10.1002/adma.202000682.

Verma C, Mishra A, Chauhan S et al (2019) Dissolution of cellulose in ionic liquids and their mixed cosolvents: a review. Sustain Chem Pharm 13:100162. https://doi.org/10.1016/j.scp.2019.100162

Wang H, Gurau G, Rogers RD (2012) Ionic liquid processing of cellulose. Chem Soc Rev 41:1519–1537. https://doi.org/10.1039/C2CS15311D

Zhang T, Liu X, Jiang M et al (2015) Effect of cellulose solubility on the thermal and mechanical properties of regenerated cellulose/graphene nanocomposites based on ionic liquid 1-allyl-3-methylimidazoliun chloride. RSC Adv 5:76302–76308. https://doi.org/10.1039/C5RA15160K

Zhang X, Wu X, Gao D, Xia K (2012) Bulk cellulose plastic materials from processing cellulose powder using back pressure-equal channel angular pressing. Carbohydr Polym 87:2470–2476. https://doi.org/10.1016/j.carbpol.2011.11.019

Zhang J, Zhang H, Wu J et al (2010) NMR spectroscopic studies of cellobiose solvation in EmimAc aimed to understand the dissolution mechanism of cellulose in ionic liquids. Phys Chem Chem Phys 12:1941. https://doi.org/10.1039/b920446f

Acknowledgments

We acknowledge the support of the State Key Laboratory of Material Processing and Die&Mould Technology at Huazhong University of Science and Technology.

Funding

This work was supported by the National Natural Science Foundation Council of China (Grant No. 51675199), China Postdoctoral Science Foundation (Grant No. 2023M730350), and Basic Science Research Projects in Higher Education Institutions in Jiangsu Province (Grant No. 23KJB460028). H.Q. acknowledges the support of the China Scholarship Council (CSC, 2018–2020) in Maryland, United States.

Author information

Authors and Affiliations

Contributions

HG, YZ, and HQ designed the experiments. HQ and XZ carried out the rheological measurements. HQ and ZY performed the FT-IR, SEM, and XRD tests. HQ, JY, and JL prepared figures and tables. HQ, YZ, and HZ collectively wrote the paper. All authors commented on the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Consent to participate

Not applicable.

Consent for publication

The authors give the publisher permission to publish the work.

Human and/or animals rights

The article does not include human participants and/or animals research.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiao, H., Zhou, X., Yu, Z. et al. Rheological properties of partially dissolved cellulose composites: the effect of cellulose content and temperature. Cellulose 30, 10701–10714 (2023). https://doi.org/10.1007/s10570-023-05525-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05525-w