Abstract

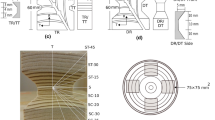

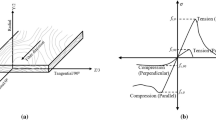

Multi-scale finite element method is adopted to simulate wood compression behavior under axial and transverse loading. Representative volume elements (RVE) of wood microfibril and cell are proposed to analyze orthotropic mechanical behavior. Lignin, hemicellulose and crystalline-amorphous cellulose core of spruce are concerned in spruce nanoscale model. The equivalent elastic modulus and yield strength of the microfibril are gained by the RVE simulation. The anisotropism of the crystalline-amorphous cellulose core brings the microfibril buckling deformation during compression loading. The failure mechanism of the cell-wall under axial compression is related to the distribution of amorphous cellulose and crystalline cellulose. According to the spruce cell observation by scanning electron microscope, numerical model of spruce cell is established using simplified circular hole and regular hexagon arrangement respectively. Axial and transverse compression loadings are taken into account in the numerical simulations. It indicates that the compression stress–strain curves of the numerical simulation are consistent with the experimental results. The wood microstructure arrangement has an important effect on the stress plateau during compression process. Cell-wall buckling in axial compression induces the stress value drops rapidly. The wide stress plateau duration means wood is with large energy dissipation under a low stress level. The numerical results show that loading velocity affects greatly wood microstructure failure modes in axial loading. For low velocity axial compression, shear sliding is the main failure mode. For high velocity axial compression, wood occur fold and collapse. In transverse compression, wood deformation is gradual and uniform, which brings stable stress plateau.

Graphic abstract

Similar content being viewed by others

References

Oudjene, M., Khelifa, M.: Elasto-plastic constitutive law for wood behaviour under compressive loadings. Constr. Build. Mater. 23, 3359–3366 (2009)

Wang, D., Lin, L.Y., Fu, F.: Deformation mechanisms of wood cell walls under tensile loading: a comparative study of compression wood (CW) and normal wood (NW). Cellulose 27, 4161–4172 (2020)

Bader, M., Nemeth, R., Konnerth, J.: Micromechanical properties of longitudinally compressed wood. Holz. Roh. Werkst. 77, 341–351 (2019)

Kojima, E., Yamasaki, M., Imaeda, K., et al.: Effects of thermal modification on the mechanical properties of the wood cell wall of soft wood: behavior of S2 cellulose microfibrils under tensile loading. J. Mater. Sci. 55, 5038–5047 (2020)

Amer, M., Kabouchi, B., Rahout, M., et al.: Mechanical properties of clonal eucalyptus wood. Int. J. Thermophys. 42, 1–15 (2021)

Dou, Q.B., Wu, K.R., Suo, T., et al.: Experimental methods for determination of mechanical behaviors of materials at high temperatures via the split Hopkinson bars. Acta Mech. Sin. 36, 1275–1293 (2020)

Song, B., Chen, W.: Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials. Exp. Mech. 44, 300–312 (2004)

Lu, B.J., Li, J.R., Tai, H.C., et al.: A facile ionic-liquid pretreatment method for the examination of archaeological wood by scanning electron microscopy. Sci. Rep. UK 9, 13253 (2019)

Song, J., Fan, C., Ma, H., et al.: Crack deflection occurs by constrained microcracking in nacre. Acta Mech. Sin. 34, 143–150 (2018)

Oliver, M., Kim, C.K., Matthias, W., et al.: Performance of thermomechanical wood fibers in polypropylene composites. Wood. Mater. Sci. Eng. 15, 114–122 (2020)

Adalian, C., Morlier, P.: A model for the behavior of wood under dynamic multiaxial compression. Compos. Sci. Technol. 61, 403–408 (2001)

Reiterer, A., Lichtenegger, H., Fratzl, P., et al.: Deformation and energy absorption of wood cell walls with different nanostructure under tensile loading. J. Mater. Sci. 36, 4681–4686 (2001)

Gong, M., Smith, I.: Effect of load type on failure mechanisms of spruce in compression parallel to grain. Wood Sci. Technol. 37, 435–445 (2004)

Johnson, W.: Historical and present-day references concerning impact on wood. Int. J. Impact Eng. 4, 161–174 (1986)

Reid, S.R., Peng, C.: Dynamic uniaxial crushing of wood. Int. J. Impact Eng. 19, 531–570 (1997)

Speck, T.: The mechanics of Norway spruce [picea abies (L.) Karst]: mechanical properties of standing trees from different thinning regimes. For. Ecol. Manag. 135, 45–62 (2000)

Widehammar, S.: Stress-strain relationships for spruce wood: influence of strain rate, moisture content and loading direction. Exp. Mech. 44, 44–48 (2004)

Buchar, J., Rolc, S., Lisy, J. et al.: Model of the wood response to the high velocity of loading. In: 19th International Symposium of Ballistics. pp. 7–11 (2001)

Holmgren, S.E., Svensson, B.A., Gradin, P.A., et al.: An encapsulated split Hopkinson pressure bar for testing of wood at elevated strain rate, temperature, and pressure. Exp. Tech. 32, 44–50 (2008)

Vural, M., Ravichandran, G.: Dynamic response and energy dissipation characteristics of balsa wood: experiment and analysis. Int. J. Solids Struct. 40, 2147–2170 (2003)

Uhmeier, A., Salmen, L.: Influence of strain rate and temperature on the radial compression behavior of wet spruce. J. Eng. Mater. Technol. ASME 118, 289–294 (1996)

Zhong, W.Z., Song, S.C., Huang, X.C., et al.: Research on static and dynamic mechanical properties of spruce wood by three loading directions. Chin. J. Theor. Appl. Mech. 43, 1141–1150 (2011)

Zhong, W.Z., Song, S.C., Chen, G., et al.: Stress field of orthotropic cylinder subjected to axial compression. Appl. Math. Mech. 31, 305–316 (2010)

Frantisek, S., Petr, K., Martin, B., et al.: Modelling of impact behaviour of European beech subjected to split Hopkinson pressure bar test. Compos. Struct. 245, (2020)

Keckes, J., Burgert, I., Frühmann, K., et al.: Cell-wall recovery after irreversible deformation of wood. Nat. Mater. 2, 810–813 (2003)

Clair, B., Thibaut, B.: Shrinkage of the gelatinous layer of poplar and beech tension wood. Iawa. J. 22, 121–131 (2001)

Salmén, L.: Micromechanical understanding of the cell-wall structure. C. R. Biol. 327, 873–880 (2004)

Li, Z., Zhan, T., Eder, M., et al.: Comparative studies on wood structure and microtensile properties between compression and opposite wood fibers of Chinese fir plantation. J. Wood. Sci. 67, 1–6 (2021)

Jäger, A., Bader, T., Hofstetter, K., et al.: The relation between indentation modulus, microfibril angle, and elastic properties of wood cell walls. Compos. A 42, 677–685 (2011)

Vasic, S., Smith, I., Landis, E.: Finite element techniques and models for wood fracture mechanics. Wood Sci. Technol. 39, 3–17 (2005)

Vasic, S., Smith, I.: Bridging crack model for fracture of spruce. Eng. Fract. Mech. 69, 745–760 (2002)

Dubois, F., Randriambololona, H., Petit, C.: Creep in wood under variable climate conditions: numerical modeling and experimental validation. Mech. Time-Depend. Mat. 9, 173–202 (2005)

Flores, E.I.S., Friswell, M.I.: Multi-scale finite element model for a new material inspired by the mechanics and structure of wood cell-walls. J. Mech. Phys. Solids 60, 1296–1309 (2012)

Flores, E.I.S., Neto, E.A.S., Pearce, C.: A large strain computational multi-scale model for the dissipative behavior of wood cell-wall. Comp. Mater. Sci. 50, 1202–1211 (2011)

Clouston, P.L., Lam, F.: Computational modeling of strand-based wood composites. J. Eng. Mech. 127, 844–851 (2001)

Li, P., Guo, Y.B., Shim, V.P.W.: Micro and mesoscale modelling of the response of transversely isotropic foam to impact: a structural cell-assembly approach. Int. J. Impact Eng. 135, (2020)

Talebi, S., Sadighi, M., Aghdam, M.M.: Numerical and experimental analysis of the closed-cell aluminium foam under low velocity impact using computerized tomography technique. Acta Mech. Sin. 35, 144–155 (2019)

Trtik, P., Dual, J., Keunecke, D., et al.: 3D imaging of microstructure of spruce wood. J. Struct. Biol. 159, 46–55 (2007)

Smith, I., Landis, E., Gong, M.: Fracture and Fatigue in Wood. Wiley, Chichester (2003)

Xu, P., Donaldson, L.A., Gergely, Z.R., et al.: Dual-axis electron tomography: a new approach for investigating the spatial organization of wood cellulose microfibrils. Wood Sci. Technol. 41, 101–116 (2007)

Donaldson, L.A., Singh, A.P.: Bridge-like structures between cellulose microfibrils in radiata pine (Pinus radiata D. Don) kraft pulp and holocellulose. Holzforsch. Int. J. Biol. Chem. Phys. Tech. Wood. 52, 449–454 (1998)

Andersson, S., Wikberg, H., Pesonen, E., et al.: Studies of crystallinity of Scots pine and Norway spruce cellulose. Trees 18, 346–353 (2004)

Andersson, S., Serimaa, R., Paakkari, T., et al.: Crystallinity of wood and the size of cellulose crystallites in Norway spruce (Picea abies). J. Wood. Sci. 49, 531–537 (2003)

Chen, W., Lickfield, G.C., Yang, C.Q.: Molecular modeling of cellulose in amorphous state. Part I: model building and plastic deformation study. Polymer. 45, 1063–1071 (2004)

Hofstetter, K., Hellmich, C., Eberhardsteiner, J.: Development and experimental validation of a continuum micromechanics model for the elasticity of wood. Eur. J. Mech. A. 24, 1030–1053 (2005)

Kilingar, N.G., Kamel, K.E.M., Sonon, B., et al.: Computational generation of open-foam representative volume elements with morphological control using distance fields. Eur. J. Mech. A 78, (2019)

Acknowledgement

This work was supported by the National Natural Science Foundation of China (Grants Nos 11302211, 11390361, and 11572299).

Author information

Authors and Affiliations

Corresponding author

Additional information

Executive Editor: Xi-Qiao Feng.

Rights and permissions

About this article

Cite this article

Zhong, W., Zhang, Z., Chen, X. et al. Multi-scale finite element simulation on large deformation behavior of wood under axial and transverse compression conditions. Acta Mech. Sin. 37, 1136–1151 (2021). https://doi.org/10.1007/s10409-021-01112-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-021-01112-z