Abstract

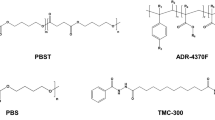

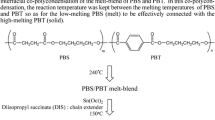

Poly(propylene carbonate phthalate) (PPC-P) is a chemically modified poly(propylene carbonate) (PPC) biodegradable thermoplastic by introducing phthalic anhydride (PA) as the third monomer into the copolymerization of propylene oxide (PO) and CO2. To enhance the thermal and mechanical properties of PPC-P, a branching agent pyromellitic anhydride (PMDA) was introduced into the terpolymerization of PO, PA and CO2. The resulting copolymers with branched structure, named branched PPC-P, can be obtained using metal-free Lewis pair consisting of triethyl borane (TEB) and bis(triphenylphosphine)iminium chloride (PPNCl) as catalyst. The products obtained were analyzed by NMR spectroscopy and their thermal, mechanical properties and melt processability were evaluated by DSC, TGA, tensile test and melt flow index (MFI) measurement. The obtained branched PPC-P has a high molecular weight up to 156.0 kg·mol−1. It shows an increased glass transition temperature (Tg) higher than 50 °C and an enhanced tensile strength as high as 38.9 MPa. Noteworthily, the MFI value decreases obviously, indicative of an improved melt strength arising from the branched structure and high molecular weight. What is more, the branched PPC-P exhibits reasonable biodegradability, which demonstrates the great potential as a new green thermoplastic for the family of biodegradable plastics.

Similar content being viewed by others

References

Xu, Y.; Lin, L.; Xiao, M.; Wang, S.; Smith, A. T.; Sun, L.; Meng, Y. Synthesis and properties of CO2-based plastics: environmentally-friendly, energy-saving and biomedical polymeric materials. Prog. Polym. Sci. 2018, 80, 163–182.

Lin, L. M.; Liang, J. X.; Xu, Y. H.; Wang, S. J.; Xiao, M.; Sun, L. Y.; Meng, Y. Z. Fully alternating sustainable polyesters from epoxides and cyclic anhydrides: economical and metal-free dual catalysis. Green Chem. 2019, 21, 2469–2477.

Chisholm, M. H.; Navarro-Llobet, D.; Zhou, Z. P. Poly(propylene carbonate). 1. More about poly(propylene carbonate) formed from the copolymerization of propylene oxide and carbon dioxide employing a zinc glutarate catalyst. Macromolecules 2002, 35, 6494–6504.

Yao, M. J.; Mai, F.; Deng, H.; Ning, N. Y.; Wang, K.; Fu, Q. A. Improved thermal stability and mechanical properties of poly(propylene carbonate) by reactive blending with maleic anhydride. J. Appl. Polym. Sci. 2011, 120, 3565–3573.

Beckman, E. J. Polymer synthesis—making polymers from carbon dioxide. Science 1999, 283, 946–947.

Luinstra, G. A. Poly(propylene carbonate), old copolymers of propylene oxide and carbon dioxide with new interests: catalysis and material properties. Polym. Rev. 2008, 48, 192–219.

Meng, Q. Y.; Cheng, R. H.; Li, J. J.; Wang, T. T.; Liu, B. P. Copolymerization of CO2 and propylene oxide using ZnGA/DMC composite catalyst for high molecular weight poly(propylene carbonate). J. CO2Util. 2016, 16, 86–96.

Inoue, S.; Koinuma, H.; Tsuruta, T. Copolymerization of carbon dioxide and epoxide. J. Polym. Sci., Part B: Polym. Lett. 1969, 7, 287–292.

Ravanchi, M. T.; Sahebdelfar, S. Catalytic conversions of CO2 to help mitigate climate change: Recent process developments. Process Saf. Environ. Protect. 2021, 145, 172–194.

Lu, X. B.; Ren, W. M.; Wu, G. P. CO2 copolymers from epoxides: catalyst activity, product selectivity, and stereochemistry control. Acc. Chem. Ree. 2012, 45, 1721–1735.

Ree, M.; Bae, J. Y.; Jung, J. H.; Shin, T. J. A new copolymerization process leading to poly(propylene carbonate) with a highly enhanced yield from carbon dioxide and propylene oxide. J. Polym. Sci., Part A: Polym. Chem. 1999, 37, 1863–1876.

Kim, G.; Ree, M.; Kim, H.; Kim, I. J.; Kim, J. R.; Lee, J. I. Biological affinity and biodegradability of poly(propylene carbonate) prepared from copolymerization of carbon dioxide with propylene oxide. Macromol. Res. 2008, 16, 473–480.

Ang, R. R.; Sin, L. T.; Bee, S. T.; Tee, T. T.; Kadhum, A. A. H.; Rahmat, A. R.; Wasmi, B. A. A review of copolymerization of green house gas carbon dioxide and oxiranes to produce polycarbonate. J. Clean Prod. 2015, 102, 1–17.

Tang, L.; Xiao, M.; Xu, Y.; Wang, S. J.; Meng, Y. Z. Zinc adipate/tertiary amine catalytic system: efficient synthesis of high molecular weight poly(propylene carbonate). J. Polym. Res. 2013, 20, 190.

Gao, L. J.; Huang, M. Y.; Wu, Q. F.; Wan, X. D.; Chen, X. D.; Wei, X. X.; Yang, W. J.; Deng, R. L.; Wang, L. Y.; Feng, J. Y. Enhanced poly(propylene carbonate) with thermoplastic networks: a cross-linking role of maleic anhydride oligomer in CO2/PO copolymerization. Polymere 2019, 11, 1467.

Cui, S. Y.; Li, L.; Wang, Q. Improved molecular chain constraint of poly(propylene carbonate) composites by the synergistic effect of poly(vinyl alcohol) and carbon nanotubes. Compos. Part B-Eng. 2020, 194, 108074.

Hao, Y.; Ge, H.; Han, L.; Liang, H.; Zhang, H.; Dong, L. Thermal, mechanical, and rheological properties of poly(propylene carbonate) cross-linked with polyaryl polymethylene isocyanate. Polym. Bull. 2013, 70, 1991–2003.

Qin, Y. S.; Ma, Q. W.; Wang, X. H.; Sun, J. Z.; Zhao, X. J.; Wang, F. S. Electron-beam irradiation on poly(propylene carbonate) in the presence of polyfunctional monomers. Polym. Degrad. Stabil. 2007, 92, 1942–1947.

Cyriac, A.; Lee, S. H.; Lee, B. Y. Connection of polymer chains using diepoxide in CO2/propylene oxide copolymerizations. Polym. Chem. 2011, 2, 950–956.

Feng, J. Y.; Gao, L. J.; Chen, B.; Wu, X. J.; Luo, Q. L.; Wu, C. Y.; Zheng, C. X.; Lin, L. Z.; Deng, S. L.; Huang, X. M. A one-step strategy for reinforced poly(propylene carbonate) with partial crosslinking via terpolymerization of CO2 and propylene oxide using triglycidyl isocyanurate. Chem. Lett. 2013, 42, 714–716.

Paul, S.; Zhu, Y. Q.; Romain, C.; Brooks, R.; Saini, P. K.; Williams, C. K. Ring-opening copolymerization (ROCOP): synthesis and properties of polyesters and polycarbonates. Chem. Commun. 2015, 51, 6459–6479.

Padmanaban, S.; Dharmalingam, S.; Yoon, S. A Zn-MOF-catalyzed terpolymerization of propylene oxide, CO2, and β-butyrolactone. Catalysts 2018, 8, 9.

Tao, Y.; Wang, X.; Zhao, X.; Li, J.; Wang, F. Double propagation based on diepoxide, a facile route to high molecular weight poly(propylene carbonate). Polymer 2006, 47, 7368–7373.

Song, P. F.; Wang, S. J.; Xiao, M.; Du, F. G.; Gan, L. Q.; Liu, G. Q.; Meng, Y. Z. Cross-linkable and thermally stable aliphatic polycarbonates derived from CO2, propylene oxide and maleic anhydride. J. Polym. Res. 2009, 16, 91–97.

Liu, S.; Wang, J.; Huang, K.; Liu, Y.; Wu, W. Synthesis of poly(propylene-co-lactide carbonate) and hydrolysis of the terpolymer. Polym. Bull. 2011, 66, 327–340.

Darensbourg, D. J.; Tsai, F. T. Ppstpolymerizotion functionalization of copolymers produced from carbon dioxide and 2-vinyloxirane: amphiphilic/water-soluble CO2-based polycarbonates. Macromolecules 2014, 47, 3806–3813.

Darensbourg, D. J.; Wang, Y. Terpolymerization of propylene oxide and vinyl oxides with CO2: copolymer cross-linking and surface modification via thiol-ene click chemistry. Polym. Chem. 2015, 6, 1768–1776.

Shi, L.; Lu, X. B.; Zhang, R.; Peng, X. J.; Zhang, C. Q.; Li, J. F.; Peng, X. M. Asymmetric alternating copolymerization and terpolymerization of epoxides with carbon dioxide at mild conditions. Macromolecules 2006, 39, 5679–5685.

Li, B.; Zhang, R.; Lu, X. B. Stereochemistry control of the alternating copolymerization of CO2 and propylene oxide catalyzed by SalenCrX complexes. Macromolecules 2007, 40, 2303–2307.

Ren, W. M.; Zhang, X.; Liu, Y.; Li, J. F.; Wang, H.; Lu, X. B. Highly active, bifunctional Co(III)-Salen catalyst for alternating copolymerization of CO2 with cyclohexene oxide and terpolymerization with aliphatic epoxides. Macromolecules 2010, 43, 1396–1402.

Liu, Y.; Xiao, M.; Wang, S.; Xia, L.; Hang, D.; Cui, G.; Meng, Y. Mechanism studies of terpolymerization of phthalic anhydride, propylene epoxide, and carbon dioxide catalyzed by ZnGA. RSC Adv. 2014, 4, 9503–9508.

Jeon, J. Y.; Eo, S. C.; Varghese, J. K.; Lee, B. Y. Copolymerization and terpolymerization of carbon dioxide/propylene oxide/phthalic anhydride using a (salen)Co(III) complex tethering four quaternary ammonium salts. Beilstein J. Org. Chem. 2014, 10, 1787–1795.

Song, P. F.; Xiao, M.; Du, F. G.; Wang, S. J.; Gan, L. Q.; Liu, G. Q.; Meng, Y. Z. Synthesis and properties of aliphatic polycarbonates derived from carbon dioxide, propylene oxide and maleic anhydride. J. Appl. Polym. Sci. 2008, 109, 4121–4129.

Liang, J.; Ye, S.; Wang, W.; Fan, C.; Wang, S.; Han, D.; Liu, W.; Cui, Y.; Hao, L.; Xiao, M.; Meng, Y. Performance tailorable terpolymers synthesized from carbon dioxide, phthalic anhydride and propylene oxide using Lewis acid-base dual catalysts. J. CO2Util. 2021, 49, 101558.

Gao, L.; Feng, J. A one-step strategy for thermally and mechanically reinforced pseudo-interpenetrating poly(propylene carbonate) networks by terpolymerization of CO2, propylene oxide and pyromellitic dianhydride. J. Mater. Chem. A 2013, 1, 3556–3560.

Chen, X. G.; Wang, L. Y.; Feng, J. Y.; Huang, X. L.; Guo, X. Z.; Chen, J.; Xiao, Z. Y.; Liang, X. J.; Gao, L. J. Enhanced poly(propylene carbonate) with thermoplastic networks: a one-pot synthesis from carbon dioxide, propylene oxide, and a carboxylic dianhydride. Polymers 2018, 10, 552.

Gao, L. J.; Chen, X. G.; Liang, X. J.; Guo, X. Z.; Huang, X. L.; Chen, C. F.; Wan, X. D.; Deng, R. Y.; Wu, Q. F.; Wang, L. Y.; Feng, J. Y. A novel one-pot synthesis of poly(propylene carbonate) containing cross-linked networks by copolymerization of carbon dioxide, propylene oxide, maleic anhydride, and furfuryl glycidyl ether. Polymers 2019, 11, 881.

Ye, S. X.; Wang, W. J.; Liang, J. X.; Wang, S. J.; Xiao, M.; Meng, Y. Z. Metal-free approach for a one-pot construction of biodegradable block copolymers from epoxides, phthalic anhydride, and CO2. ACS Sustain. Chem. Eng. 2020, 8, 17860–17867.

Zhang, D.; Boopathi, S. K.; Hadjichristidis, N.; Gnanou, Y.; Feng, X. Metal-free alternating copolymerization of CO2 with epoxides: fulfilling “green” synthesis and activity. J. Am. Chem. Soc. 2016, 138, 11117–11120.

Zhang, D. D.; Feng, X.; Gnanou, Y.; Huang, K. W. Theoretical mechanistic investigation into metal-free alternating copolymerization of CO2 and epoxides: the key role of triethylborane. Macromolecules 2018, 51, 5600–5607.

Varghese, J. K.; Hadjichristidis, N.; Gnanou, Y.; Feng, X. Degradable poly(ethylene oxide) through metal-free copolymerization of ethylene oxide with L-lactide. Polym. Chem. 2019, 10, 3764–3771.

Chen, Z.; Yang, J. L.; Lu, X. Y.; Hu, L. F.; Cao, X. H.; Wu, G. P.; Zhang, X. H. Triethyl borane-regulated selective production of polycarbonates and cyclic carbonates for the coupling reaction of CO2 with epoxides. Polym. Chem. 2019, 10, 3621–3628.

Li, Y.; Zhang, Y. Y.; Hu, L. F.; Zhang, X. H.; Du, B. Y.; Xu, J. T. Carbon dioxide-based copolymers with various architectures. Prog. Polym. Sci. 2018, 82, 120–157.

Zhang, J.; Wang, L.; Liu, S.; Kang, X.; Li, Z. A lewis pair as organocatalyst for one-pot synthesis of block copolymers from a mixture of epoxide, anhydride, and CO2. Macromolecules 2021, 54, 763–772.

Chidara, V. K.; Boopathi, S. K.; Hadjichristidis, N.; Gnanou, Y.; Feng, X. S. Triethylborane-assisted synthesis of random and block poly(estercarbonate)s through one-pot terpolymerization of epoxides, CO2, and cyclic anhydrides. Macromolecules 2021, 54, 2711–2719.

Duan, J. T.; Wang, J. J.; Feng, L. F.; Wang, L.; Gu, X. P. Pressure dependence of the CO2/propylene oxide copolymerization catalyzed by zinc glutarate. J. Appl. Polym. Sci. 2010, 118, 366–371.

Darensbourg, D. J.; Mackiewicz, R. M.; Billodeaux, D. R. Pressure dependence of the carbon dioxide/cyclohexene oxide coupling reaction catalyzed by chromium salen complexes. optimization of the comonomer-alternating enchainment pathway. Organometallics 2005, 24, 144–148.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51673131) and the Fundamental Research Funds for the Central Universities (No. 171gjc37).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Notes

The authors declare no competing financial interest.

Electronic Supplementary Information

10118_2022_2686_MOESM1_ESM.pdf

Architecting Branch Structure in Terpolymer of CO2, Propylene Oxide and Phthalic Anhydride: An Enhancement in Thermal and Mechanical Performances

Rights and permissions

About this article

Cite this article

Wang, WJ., Ye, SX., Liang, JX. et al. Architecting Branch Structure in Terpolymer of CO2, Propylene Oxide and Phthalic Anhydride: An Enhancement in Thermal and Mechanical Performances. Chin J Polym Sci 40, 462–468 (2022). https://doi.org/10.1007/s10118-022-2686-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-022-2686-4