Abstract

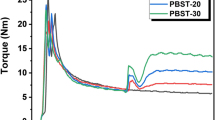

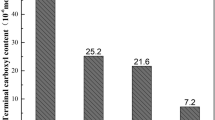

Poly(butylene succinate-co-terephthalate) (PBST) is an aliphatic–aromatic copolymer with excellent biodegradability and high flexibility, which can be used to replace traditional non-degradable polymer materials in various fields. However, its relatively low heat distortion temperature limits its applicability. Herein, poly(butylene succinate) (PBS) was blended with PBST to enhance the heat resistance of PBST. The chain extender ADR-4370F was used as a reactive compatibilizer to improve the compatibility between PBST and PBS. The hydrazide compound TMC-300 was use as a nucleating agent to improve the PBST/PBS blend's crystallization behavior and prepare a novel and eco-friendly PBST/PBS-based blend. The morphology of the cryo-fractured surfaces of PBST/PBS blends showed that the compatibility between PBST and PBS improved significantly upon adding ADR. Furthermore, compared to the PBST/PBS blend, Young's modulus, tensile strength, breaking strain, and breaking energy of the PBST/PBS/ADR blend showed great improvement. In addition, DSC results showed that the crystallization temperature (Tc) of PBST and PBS of PBST/PBS/ADR/TMC blend increased with increasing TMC content. WAXD results showed that the degree of crystallinity of PBST/PBS/ADR/TMC blends increased with incorporating PBS and TMC, increasing the Vicat softening temperature. Compared with neat PBST, the heat resistance of the PBST/PBS-based blend was improved.

Similar content being viewed by others

References

Cross RA, Kalra B (2002) Biodegradable polymers for the environment. Science 297:803–807

Williams CK, Hillmyer MA (2008) Polymers from renewable resources: a perspective for a special issue of polymer reviews. Polym Rev 48:1–10

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602

Zhao Y, Zhao BH, Wei BL, Wei YX, Yao JR, Zhang HL, Chen X, Shao ZZ (2020) Enhanced compatibility between poly(lactic acid) and poly (butylene adipate-co-terephthalate) by incorporation of N-halamine epoxy precursor. Int J Biol Macromol 165:460–471

Zhao Y, Wei BL, Wu M, Zhang HL, Yao JR, Chen X, Shao ZZ (2020) Preparation and characterization of antibacterial poly(lactic acid) nanocomposites with N-halamine modified silica. Int J Biol Macromol 155:1468–1477

Luo SL, Li FX, Yu JY (2011) The thermal, mechanical and viscoelastic properties of poly(butylene succinate-co-terephthalate) (PBST) copolyesters with high content of BT units. J Polym Res 18:393–400

Luo SL, Li FX, Yu JY, Cao AM (2010) Synthesis of poly(butylene succinate-co- butylene terephthalate) (PBST) copolyesters with high molecular weights via direct esterification and polycondensation. J Appl Polym Sci 115:2203–2211

Li FX, Luo SL, Ma C, Yu JY, Cao AM (2010) The crystallization and morphology of biodegradable poly(butylene succinate-co-terephthalate) copolyesters with high content of BT units. J Appl Polym Sci 118:623–630

Wei ZZ, Lin JY, Wang XL, Huang LQ, Yu JY, Li FX (2015) In situ polymerization of biodegradable poly(butylene-co-succinate terephthalate) nanocomposites and their real-time tracking of microstructure. Compos Sci Technol 117:121–129

Wei ZZ, Liu YL, Wang XL, Yu JY, Li FX (2016) Real-time tracking of the hierarchical structure of biodegradable poly(butylene succinate-co-terephthalate) nanocomposites with fibrous attapulgite nanoparticles. Compos Sci Technol 134:201–208

Lin SH, Wang JM, Wang HT, Wu TM (2019) Synthesis, mechanical properties and biodegradation of various acrylic acid-grafted poly(butylene succinate-co- terephthalate)/organically modified layered zinc phenylphosphonate nanocomposites. Eur Polym J 116:1–8

Wang JM, Ding SJ, Wu TM (2020) Rheology, crystallization behavior, and mechanical properties of poly(butylene succinate-co-terephthalate)/cellulose nanocrystal composites. Polym Test 87:106551

Yan XY, Xie RH, Pan HW, Zhao T, Han LJ, Bian JJ, Yang HL, Zhao Y, Wu GF, Zhang HL (2022) Effect of 1,4-bis(tert-butyl peroxy isopropyl) benzene on the rheological, mechanical, thermal and barrier properties of poly(butylene succinate-co-terephthalate)/poly(lactic acid) blends and blown films. Mater Today Commun 31:103830

Wang XY, Pan HW, Jia SL, Wang ZP, Tian HL, Han LJ, Zhang HL (2022) In-situ reaction compatibilization modification of poly(butylene succinate-co-terephthalate)/polylactide acid blend films by multifunctional epoxy compound. Int J Biol Macromol 213:934–943

Bian JJ, Han LJ, Wang XM, Wen X, Han CY, Wang SS, Dong LS (2010) Nonisothermal crystallization behavior and mechanical properties of poly(butylene succinate)/silica nanocomposites. J Appl Polym Sci 116:902–912

Li Y, Han CY, Xiao LG, Yu YC, Zhou GB, Xu MZ (2021) Miscibility, morphology, and properties of poly(butylene succinate)/poly(vinyl acetate) blends. Colloid Polym Sci 299:105–116

Wang XM, Zhuang YG, Dong LS (2012) Study of carbon black-filled poly(butylene succinate)/polylactide blend. J Appl Polym Sci 126:1876–1884

Liu B, Guan TH, Wu G, Fu Y, Weng YX (2022) Biodegradation behavior of degradable mulch with poly(butylene adipate-co-terephthalate) (PBAT) and poly(butylene succinate) (PBS) in simulation marine environment. Polymers 14:1515

Gao JC, Wu YD, Li J, Peng XQ, Wang YDW, JC, Wang XH, Jin MJ, Yao ZW, Shen XJ, Wang S, Jin HL (2022) Toughening and heat-resistant modification of degradable PLA/PBS-based composites by using glass fiber/silicon dioxide hybrid fillers. Polymers 14:3237

Prasong W, Ishigami A, Thumsorn S, Kurose T, Ito H (2021) Improvement of interlayer adhesion and heat resistance of biodegradable ternary blend composite 3D printing. Polymers 13:740

Zhang KY, Mohanty AK, Misra M (2012) Fully biodegradable and biorenewable ternary blends from polylactide, poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) with balanced properties. ACS Appl Mater Interfaces 4:091–3101

Li FX, Xu XJ, Hao QH, Li QB, Yu JY, Cao AM (2006) Effects of comonomer sequential structure on thermal and crystallization behaviors of biodegradable poly(butylene succinate-co-butylene terephthalate)s. J Appl Polym Sci 44:1635–1644

Zheng C, Zhu GX, Shi Y, Liu LZ, Ren MQ, Zhang W, Han L (2021) Crystallization, structures and properties of biodegradable poly (butylene succinate-co-butylene terephthalate) with a symmetric composition. Mater Chem Phys 260:124183

Urbanek AK, Mirończuk AM, García-Martín A, Saborido A, Mata I, Arroyo M (2020) Biochemical properties and biotechnological applications of microbial enzymes involved in the degradation of polyester-type plastics. BBA-Proteins Proteom 1868:140315

Lee CW, Akashi M, Kimura Y, Masutani K (2017) Synthesis and enzymatic degradability of an aliphatic/aromatic block copolyester: poly(butylene succinate)-multi-poly(butylene terephthalate). Macromol Res 25:54–62

Wu DD, Guo Y, Huang AP, Xu RW, Liu P (2021) Effect of the multi-functional epoxides on the thermal, mechanical and rheological properties of poly(butylene adipate-co-terephthalate)/polylactide blends. Polym Bull 78:5567–5591

Zhang Y, Jia SL, Pan HW, Wang LJ, Zhang HL, Yang HL, Dong LS (2021) Preparation, characterization and properties of biodegradable poly(butylene adipate-co-butylene terephthalate)/thermoplastic poly(propylene carbonate) polyurethane blend films. Polym Adv Technol 32:613–629

Jia SL, Wang XY, Zhang Y, Yan XY, Pan HW, Zhao Y, Han LJ, Zhang HL, Dong LS, Zhang HX (2022) Superior toughened biodegradable poly(L-lactic acid)-based blends with enhanced melt strength and excellent low-temperature toughness via in-situ reaction compatibilization. Chinese J Polym Sci. https://doi.org/10.1007/s10118-022-2862-6

Liu S, He Y, Qu JP (2022) Manufacturing high-performance polylactide by constructing 3D network crystalline structure with adding self-assembly nucleator. Ind Eng Chem Res 61:4567–4578

Li CH, Jiang T, Wang JF, Peng SJ, Wu H, Shen JB, Guo SY, Zhang X, Harkin-Jones E (2018) Enhancing the oxygen-barrier properties of polylactide by tailoring the arrangement of crystalline lamellae. ACS Sustainable Chem Eng 6:6247–6255

Tang YJ, Wang YQ, Chen SH, Wang XD (2022) Fabrication of low-density poly(lactic acid) microcellular foam by self-assembly crystallization nucleating agent. Polym Degrad Stab 198:109891

Feng YQ, Ma PM, Xu PW, Wang RY, Dong WF, Chen MQ, Joziasse C (2018) The crystallization behavior of poly(lactic acid) with different types of nucleating agents. Int J Biol Macromol 106:955–962

Li XY, Yang LZ, Zhai GQ, Gao WQ, Wang KZ, Li XG (2021) Effect of nucleating agent on crystallization and properties of poly(butylene succinate). China Plastics 35:146–151

Wu DD, Xu RW, Zhang YH, Shi SX (2022) Influence of branching on the mechanical, rheological and crystallization properties of poly(butylene adipate-co-terephthalate). J Therm Anal Calorim 147:9539–9557

Xu PF, Tian HL, Han LJ, Yang HL, Bian JJ, Pan HW, Zhang HL (2022) Improved heat resistance in poly (lactic acid)/ethylene butyl methacrylate glycidyl methacrylate terpolymer blends by controlling highly filled talc particles. J Therm Anal Calorim 147:5719–5732

Yu T, Jiang N, Li Y (2014) Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos Part A 64:139–146

Deng L, Xu C, Wang XH, Wang ZG (2018) Supertoughened polylactide binary blend with high heat deflection temperature achieved by thermal annealing above the glass transition temperature. ACS Sustainable Chem Eng 6:480–490

Katekhong W, Wongphan P, Klinmalai P, Harnkarnsujarit N (2022) Thermoplastic starch blown films functionalized by plasticized nitrite blended with PBAT for superior oxygen barrier and active biodegradable meat packaging. Food Chem 374:131709

Li Y, Yu YC, Han CY, Wang XH, Huang DX (2020) Sustainable blends of poly(propylene carbonate) and stereocomplex polylactide with enhanced rheological properties and heat resistance Chinese J Polym Sci 38:1267–1275

Zhao HW, Liu H, Liu YQ, Yang Y (2020) Blends of poly(butylene adipate-co-terephthalate) (PBAT) and stereocomplex polylactide with improved rheological and mechanical properties. RSC Adv 10:10482–10490

Acknowledgements

This work was supported by the fund of the Chinese Academy of Sciences (Changchun Branch) (Nos. 2022SYHZ0033; 2022SYHZ0037); the Science and Technology Bureau of Changchun City of China (No. 21SH13); the Development and Reform Commission of Jilin Province of China (No. 2022C039-3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, X., Chen, L., Tian, H. et al. Enhancement of the compatibility, mechanical properties, and heat resistance of poly(butylene succinate-co-terephthalate)/poly(butylene succinate) blends by the addition of chain extender and nucleating agent. J Polym Res 30, 111 (2023). https://doi.org/10.1007/s10965-023-03486-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03486-z