Abstract

To ensure the stability of product quality and production continuity, quality control is drawing increasing attention from the process industry. However, current methods cannot meet requirements with regard to time series data, high coupling parameters, delayed data acquisition, and ambiguous operation control. A digital twin–driven (DTD) method is proposed for real-time monitoring, evaluation, and optimization of process parameters that are strongly related to product quality. Based on a process simulation model, production status information and quality related data are obtained. Combined with an improved genetic algorithm (GA), a time sequential prediction model of bidirectional gated recurrent unit (bi-GRU) with attention mechanism (AM) is built to flexibly allocate parameter weights, accurately predict product quality, timely evaluate technical process, and rapidly generate optimized control plans. A typical case study and relevant field tests from the process industry are presented to prove the effectiveness of the method. Results indicate that the proposed method clearly outperforms its competitors.

Similar content being viewed by others

Availability of data and material

The datasets and technical materials generated and analyzed during the current study are not publicly available due to corporate security and we cannot disclose it.

Code availability

Not applicable.

References

Qian F, Zhong W, Du WL (2017) Fundamental theories and key technologies for smart and optimal manufacturing in the process industry. Engineering 3(2):154–160. https://doi.org/10.1016/J.Eng.2017.02.011

Du SC, Xu R, Li L (2018) Modeling and analysis of multiproduct multistage manufacturing system for quality improvement. IEEE Trans Syst Man Cybern Syst 48(5):801–820. https://doi.org/10.1109/TSMC.2016.2614766

Zhang RD, Lu JY, Qu HY, Gao F (2014) State space model predictive fault-tolerant control for batch processes with partial actuator failure. J Process Contr 24(5):613–620. https://doi.org/10.1016/j.jprocont.2014.03.004

He YL, Ma YC, Xu Y, Zhu Q (2020) Fault diagnosis using novel class-specific distributed monitoring weighted naive Bayes: applications to process industry. Ind Eng Chem Res 59(20):9593–9603. https://doi.org/10.1021/acs.iecr.0c01071

Kim KS, Ko JW (2005) Real-time risk monitoring system for chemical plants. Korean J Chem Eng 22(1):26–31. https://doi.org/10.1007/Bf02701457

Mendibil X, Llanos I, Urreta H, Quintana I (2017) In process quality control on micro inje-ction moulding: the role of sensor location. Int J Adv Manuf Tech 89(9–12):3429–3438. https://doi.org/10.1007/s00170-016-9300-2

Cao J, He Y, Zhu QX (2021) An ontology-based procedure knowledge framework for the process industry. Can J Chem Eng 99(2):530–542. https://doi.org/10.1002/cjce.23873

Zhang D, Gao XW (2021) Soft sensor of flotation froth grade classification based on hybrid deep neural network. Int J Prod Res 4794–4810. https://doi.org/10.1080/00207543.2021.1894366

Park SH, Park C, Kim J, Baek J (2017) Principal curve-based monitoring chart for anomaly detection of non-linear process signals. Int J Adv Manuf Tech 90(9–12):3523–3531. https://doi.org/10.1007/s00170-016-9624-y

Stavridis J, Papacharalampopoulos A, Stavropoulos P (2018) Quality assessment in laser welding: a critical review. Int J Adv Manuf Tech 94(5–8):1825–1847. https://doi.org/10.1007/s00170-017-0461-4

Assis AJ, Maciel R (2000) Soft sensors development for on-line bioreactor state estimation. Comput Chem Eng 24(2–7):1099–1103. https://doi.org/10.1016/S0098-1354(00)00489-0

Yuan X, Ge Z, Song Z, Wang Y, Yang C, Zhang H (2017) Soft sensor modeling of nonlinear industrial processes based on weighted probabilistic projection regression. IEEE T Instrum Meas 66(4):837–845. https://doi.org/10.1109/Tim.2017.2658158

Penaloza EAG, Oliveira VA, Cruvinel PE (2021) Using soft sensors as a basis of an innovative architecture for operation planning and quality evaluation in agricultural sprayers. Sensors-Basel 21(4):1269. https://doi.org/10.3390/s21041269

Kneale C, Brown S (2018) Small moving window calibration models for soft sensing proc-esses with limited history. Chemometr Intell Lab 183:36–46. https://doi.org/10.1016/j.chemolab.2018.10.007

Fu Y, Yang W, Xu O, Zhou L, Wang J (2017) Soft sensor modelling by time difference, recursive partial least squares and adaptive model updating. Meas Sci Technol 28(4):045101. https://doi.org/10.1088/1361-6501/aa57e2

Pisa I, Santin I, Vicario J, Morell A, Vilanova R (2019) ANN-based soft sensor to predict effluent violations in wastewater treatment plants. Sensors-Basel 19(6):1280. https://doi.org/10.3390/s19061280

Jana AK, Banerjee S (2018) Neuro estimator-based inferential extended generic model cont-rol of a reactive distillation column. Chem Eng Res Des 130:284–294. https://doi.org/10.1016/j.cherd.2017.12.041

Kadlec P, Gabrys B, Strandt S (2009) Data-driven soft sensors in the process industry. Comput Chem Eng 33(4):795–814. https://doi.org/10.1016/j.compchemeng.2008.12.012

Liu X, Jin J, Wu W, Herz F (2020) A novel support vector machine ensemble model for estimation of free lime content in cement clinkers. ISA T 99:479–487. https://doi.org/10.1016/j.isatra.2019.09.003

Wang T, Wang X, Ma R, Li X, Hu X, Chan F, Ruan J (2020) Random forest-Bayesian optimization for product quality prediction with large-scale dimensions in process industrial cyber-physical systems. IEEE Internet Things 7(9):8641–8653. https://doi.org/10.1109/Jiot.2020.2992811

Li YG, Gui WH, Yang CH, Xie Y (2013) Soft sensor and expert control for blending and digestion process in alumina metallurgical industry. J Process Contr 23(7):1012–1021. https://doi.org/10.1016/j.jprocont.2013.06.002

Aslam M, Bantan RAR, Khan N (2019) Design of X-bar control chart using multiple dep-endent state sampling under indeterminacy environment. IEEE Access 7:152233–152242. https://doi.org/10.1109/Access.2019.2947598

Chen S, Yu J (2019) Deep recurrent neural network-based residual control chart for autocorrelated processes. Qual Reliab Eng Int 35(8):2687–2708. https://doi.org/10.1002/qre.2551

Keshavarz M, Asadzadeh S, Niaki STA (2019) Controlling autocorrelated data in multistage manufacturing processes with an application to textile industry. Qual Reliab Eng Int 35(7):2314–2326. https://doi.org/10.1002/qre.2512

Lee CKH, Choy KL, Ho GTS, Lam CHY (2016) A slippery genetic algorithm-based process mining system for achieving better quality assurance in the garment industry. Expert Syst Appl 46(236–248). https://doi.org/10.1016/j.eswa.2015.10.035

Kramar D, Cica D (2017) Predictive model and optimization of processing parameters for plastic injection moulding. Mater Tehnol 51(4):597–602. https://doi.org/10.17222/mit.2016.129

Grieves MW (2005) Product lifecycle management: the new paradigm for enterprises. Int J Prod Dev 2(1–2):71–84. https://doi.org/10.1504/IJPD.2005.006669

Tao F, Zhang L, Nee AYC, Pickl SW (2016) Editorial for the special issue on big data and cloud technology for manufacturing. Int J Adv Manuf Tech 84(1–4):1–3. https://doi.org/10.1007/s00170-016-8495-6

Zhang X, Ming X, Liu Z, Yin D, Chen Z, Chang Y (2019) A reference framework and overall planning of industrial artificial intelligence (I-AI) for new application scenarios. Int J Adv Manuf Tech 101(9–12):2367–2389. https://doi.org/10.1007/s00170-018-3106-3

Ye YX, Hu TL, Zhang CR, Luo W (2018) Design and development of a CNC machining process knowledge base using cloud technology. Int J Adv Manuf Tech 94(9–12):3413–3425. https://doi.org/10.1007/s00170-016-9338-1

Balderas D, Ortiz A, Méndez E, Ponce P, Molina A (2021) Empowering Digital Twin for Industry 4.0 using metaheuristic optimization algorithms:case study PCB drilling optimization. Int J Adv Manuf Tech 113(5):1295–1306. https://doi.org/10.1007/s00170-021-06649-8

Tao F, Zhang M (2017) Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5:20418–20427. https://doi.org/10.1109/Access.2017.2756069

Tao F, Cheng JF, Qi QL, Zhang M, Zhang H, Sui FY (2018) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Tech 94(9–12):3563–3576. https://doi.org/10.1007/s00170-017-0233-1

Li CZ, Mahadevan S, Ling Y, Choze S, Wang LP (2017) Dynamic Bayesian network for aircraft wing health monitoring digital twin. AIAA J 55(3):930–941. https://doi.org/10.2514/1.J055201

Tao F, Zhang M, Liu YS, Nee A (2018) Digital twin driven prognostics and health mana-gement for complex equipment. Cirp Ann-Manuf Techn 67(1):169–172. https://doi.org/10.1016/j.cirp.2018.04.055

Iglesias D, Bunting P, Esquembri S, Hollocombe J, Silburn S, Vitton-Mea L, Balboa I, Huber A, Matthews GF, Riccardo V, Rimini F, Valcarcel D (2017) Digital twin applications for the JET divertor. Fusion Eng Des 125:71–76. https://doi.org/10.1016/j.fusengdes.2017.10.012

Liu JF, Zhou HG, Tian GZ, Liu XJ, Jing X (2019) Digital twin-based process reuse and evaluation approach for smart process planning. Int J Adv Manuf Tech 100(5–8):1619–1634. https://doi.org/10.1007/s00170-018-2748-5

Soderberg R, Warmefjord K, Carlson JS, Lindkvist L (2017) Toward a digital twin for real-time geometry assurance in individualized production. Cirp Ann-Manuf Techn 66(1):137–140. https://doi.org/10.1016/j.cirp.2017.04.038

Zhuang CB, Liu JH, Xiong H (2018) Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int J Adv Manuf Tech 96(1–4):1149–1163. https://doi.org/10.1007/s00170-018-1617-6

Wang X, Wang L (2019) Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0. Int J Prod Res 57(12):3892–3902. https://doi.org/10.1080/00207543.2018.1497819

Zheng Y, Yang S, Cheng HC (2019) An application framework of digital twin and its case study. J Amb Intel Hum Comp 10(3):1141–1153. https://doi.org/10.1007/s12652-018-0911-3

He R, Chen G, Dong C, Sun S, Shen XY (2019) Data-driven digital twin technology for optimized control in process systems. ISA T 95:221–234. https://doi.org/10.1016/j.isatra.2019.05.011

Lee J, Noh S, Kim H, Kang Y (2018) Implementation of cyber-physical production systems for quality prediction and operation control in metal casting. Sensors-Basel 18(5):1428. https://doi.org/10.3390/s18051428

Dli M, Puchkov A, Meshalkin V, Abdeev I, Saitov R, Abdeev R (2020) Energy and resource efficiency in apatite-nepheline ore waste processing using the digital twin approach. Energies 13(21):5829. https://doi.org/10.3390/en13215829

Prathima BA, Sudha PN, Suresh P (2020) Shop floor to cloud connect for live monitoring the production data of CNC machines. Int J Comput Integ M 33(2):142–158. https://doi.org/10.1080/0951192x.2020.1718762

Kannan K, Arunachalam N (2019) A digital twin for grinding wheel:an information sharing platform for sustainable grinding process. J Manuf Sci E-T Asme 141(2):021015. https://doi.org/10.1115/1.4042076

Cheng Y, Zhang Y, Ji P, Xu W, Zhou Z, Tao F (2018) Cyber-physical integration for mo-ving digital factories forward towards smart manufacturing: a survey. Int J Adv Manuf Tech 97(1–4):1209–1221. https://doi.org/10.1007/s00170-018-2001-2

Schmidhuber J (2015) Deep learning in neural networks: an overview. Neural Netw 61:85–117. https://doi.org/10.1016/j.neunet.2014.09.003

Hochreiter S, Schmidhuber J (1997) Long short-term memory. Neural Comput 9(8):1735–1780. https://doi.org/10.1162/neco.1997.9.8.1735

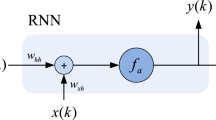

Cho K, Merrienboer B, Gulcehre C, Bahdanau D, Bougares F, Schwenk H, Bengio Y (2014) Learning phrase representations using RNN encoder-decoder for statistical machine translation. Computer Science. https://arxiv.org/abs/1406.1078

Liu G, Guo J (2019) Bidirectional LSTM with attention mechanism and convolutional layer for text classification. Neurocomputing 337:325–338. https://doi.org/10.1016/j.neucom.2019.01.078

Maulik U, Bandyopadhyay S (2000) Genetic algorithm-based clustering technique. Pattern Recogn 33(9):1455–1465. https://doi.org/10.1016/S0031-3203(99)00137-5

Funding

This research is supported by the National Natural Science Foundation of China (No. 51975521).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, X., Ji, Y. A digital twin–driven method for online quality control in process industry. Int J Adv Manuf Technol 119, 3045–3064 (2022). https://doi.org/10.1007/s00170-021-08369-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08369-5