Abstract

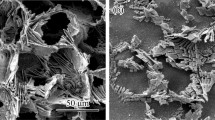

One important challenge in producing high-speed steels (HSSs) by conventional route is how to improve their hot workability. In this work, the effect of high-temperature annealing on the microstructure evolution and hot deformation behavior of the as-cast high-nitrogen M42 HSS was studied. The results indicated that the as-cast microstructure of high-nitrogen M42 HSS mainly consisted of the dendrite cells of matrix, interdendritic network of M2C eutectic carbides, primary M(C,N) carbonitrides, and intradendritic fine M2C secondary carbides. After high-temperature annealing, M2C eutectic carbides were transformed into M6C and M(C,N) products via a diffusion-driven reaction of M2C + matrix → M6C + M(C,N), and M6C carbides were the dominant products. Initially, M6C and M(C,N) nucleated at the M2C/matrix interface, and then grew inward from outside. With increasing annealing temperature and time, the average length–width ratio of interdendritic mixed carbides of M2C and M6C gradually decreased. The full decomposition and breaking of M2C eutectic carbides in the as-cast high-nitrogen M42 HSS could be achieved by annealing at 1100 °C for 8 hours. Meanwhile, high-temperature annealing led to the decreased amount of intradendritic M2C secondary carbides and the formation of M6C carbides within the intradendritic region. The high-temperature annealed steel exhibited higher flow stress than the as-cast steel at most deformation conditions, but lower deformation activation energy. The macroscopic morphologies showed that the hot workability of the high-temperature annealed steel was evidently better than that of the as-cast steel, which could be attributed to its better deformation compatibility and more sufficient dynamic recrystallization (DRX). Moreover, high-temperature annealing treatment led to a more uniform carbide distribution after hot compression. Therefore, high-temperature annealing treatment may provide an opportunity to further maintain or even improve the competitiveness of HSS produced by conventional route compared with those by powder metallurgy.

Similar content being viewed by others

References

W.C. Jiao, H.B. Li, H. Feng, Z.H. Jiang, J. Dai, H.C. Zhu, S.C. Zhang, M.S. Chu, and W. Wu: ISIJ Int., 2020, vol. 60, pp. 564–72.

D. Bombač, M. Terčelj, M. Fazarinc, and G. Kugler: Mater. Sci. Eng. A., 2017, vol. 703, pp. 438–50.

H.L. Peng, L. Hu, T.W. Ngai, L.J. Li, X.L. Zhang, H. Xie, and W.P. Gong: Mater. Sci. Eng. A., 2018, vol. 719, pp. 21–26.

Y.H. Liu, Y.Q. Ning, Z.K. Yao, and M.W. Fu: Mater. Des., 2014, vol. 54, pp. 854–63.

W.C. Jiao, H.B. Li, H. Feng, Z.H. Jiang, L.F. Xia, S.C. Zhang, H.C. Zhu, and W. Wu: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 2240–51.

H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, W.C. Jiao, S.C. Zhang, P.B. Wang, and J.H. Zhu: ISIJ Int., 2018, vol. 58, pp. 1267–74.

Y.W. Luo, H.J. Guo, X.L. Sun, J. Guo, and F. Wang: Metall. Mater. Trans. A., 2018, vol. 49A, pp. 5976–86.

M.A. Hamidzadeh, M. Meratian, and A. Saatchi: Mater. Sci. Eng. A, 2013, vol. 571, pp. 193–98.

P.D. Ding, G.Q. Shi, and S.Z. Zhou: Metall. Mater. Trans. A, 1993, vol. 24A, pp. 1265–72.

X.F. Zhou, W.L. Zhu, H.B. Jiang, F. Fang, Y.Y. Tu, and J.Q. Jiang: J. Iron Steel Res. Int., 2016, vol. 23, pp. 800–07.

F.S. Pan, W.Q. Wang, A.T. Tang, L.Z. Wu, T.T. Liu, and R.J. Cheng: Prog. Nat. Sci-Mater., 2011, vol. 21, pp. 180–86.

E.S. Lee, W.J. Park, J.Y. Jung, and S. Ahn: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1395–1404.

J. Hufenbach, A. Helth, M.H. Lee, H. Wendrock, L. Giebeler, C.Y. Choe, K.H. Kim, U. Kühn, T.S. Kim, and J. Eckert: Mater. Sci. Eng. A, 2016, vol. 674, pp. 366–74.

X.F. Zhou, X.Y. Yin, F. Fang, J.Q. Jiang, and W.L. Zhu: J. Rare Earths., 2012, vol. 30, pp. 1075–78.

M. Boccalini and H. Goldenstein: Int. Mater. Rev., 2001, vol. 46, pp. 92–115.

Y.K. Luan, N.N. Song, Y.L. Bai, X.H. Kang, and D.Z. Li: J. Mater. Process. Technol., 2010, vol. 210, pp. 536–41.

M. Godec, T. Večko Pirtovšek, B. Šetina Batič, P. McGuiness, J. Burja, and B. Podgornik: Sci. Rep., 2015, vol. 5, p. 16202.

X.F. Zhou, W.C. Zhang, Z.X. Zheng, D. Liu, F. Fang, Y.Y. Tu, and J.Q. Jiang: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 3552–64.

W.F. Liu, Y.F. Guo, Y.F. Cao, J.Q. Wang, Z.Y. Hou, M.Y. Sun, B. Xu, and D.Z. Li: J. Alloys Compd., 2021, vol. 889, p. 161755.

X.F. Zhou, D. Liu, W.L. Zhu, F. Fang, Y.Y. Tu, and J.Q. Jiang: J. Iron Steel Res. Int., 2017, vol. 24, pp. 43–49.

Y.W. Luo, H.J. Guo, X.L. Sun, and J. Guo: Sci. Rep., 2018, vol. 8, p. 4328.

L. Chen, J.M. Pei, F. Li, Y.J. Zhang, M.J. Wang, and X.C. Ma: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 5662–69.

L. Lu, L.G. Hou, J.X. Zhang, H.B. Wang, H. Cui, J.F. Huang, Y.A. Zhang, and J.S. Zhang: Mater. Charact., 2016, vol. 117, pp. 1–8.

M.R. Ghomashchi: Acta Mater., 1998, vol. 46, pp. 5207–20.

Z.Y. He, H.B. Li, Z.W. Ni, H.C. Zhu, Z.H. Jiang, H. Feng, and D.S. Mao: Steel Res. Int., 2021, vol. 92, p. 2100197.

Y. Han, H.B. Li, H. Feng, K.M. Li, Y.Z. Tian, and Z.H. Jiang: J. Mater. Sci. Technol., 2021, vol. 65, pp. 210–15.

S.C. Zhang, J.T. Yu, H.B. Li, Z.H. Jiang, Y.F. Geng, H. Feng, B.B. Zhang, and H.C. Zhu: J. Mater. Sci. Technol., 2022, vol. 102, pp. 105–14.

H. Feng, Z.H. Jiang, H.B. Li, P.C. Lu, S.C. Zhang, H.C. Zhu, B.B. Zhang, T. Zhang, D.K. Xu, and Z.G. Chen: Corros. Sci., 2018, vol. 144, pp. 288–300.

Y. Han, H.B. Li, H. Feng, Y.Z. Tian, Z.H. Jiang, and T. He: Mater. Sci. Eng. A., 2021, vol. 814, p. 141235.

S.C. Zhang, H.B. Li, Z.H. Jiang, Z.X. Li, J.X. Wu, B.B. Zhang, F. Duan, H. Feng, and H.C. Zhu: J. Mater. Sci. Technol., 2020, vol. 42, pp. 143–55.

National Standard GB/T 14979-1994: Eutectic carbide of steel - Micrographic method using standard diagrams, The State Bureau of Technical Supervision, 1994.

C. Ai, L. Liu, J. Zhang, M. Guo, Z.R. Li, T.W. Huang, J. Zhou, S.S. Li, S.K. Gong, and G. Liu: J. Alloys Compd., 2018, vol. 754, pp. 85–92.

L. Gong, B. Chen, L. Zhang, Y.C. Ma, and K. Liu: J. Mater. Sci. Technol., 2018, vol. 34, pp. 811–20.

T.P. Hou, Y. Li, Y.D. Zhang, and K.M. Wu: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 2553–61.

M. Hashimoto, O. Kubo, and Y. Matsubara: ISIJ Int., 2004, vol. 44, pp. 372–80.

R.G. Shephard, J.D.L. Harrison, and L.E. Russell: Powder Metall., 1973, vol. 16, pp. 200–19.

X.F. Zhou, F. Fang, J.Q. Jiang, W.L. Zhu, and H.X. Xu: Mater. Sci. Techol.-Lond., 2012, vol. 28, pp. 1499–504.

A.S. Chaus, M. Beznák, M. Bohačík, J. Porubský, and P. Úradník: Defect Diffus. Forum., 2012, vol. 326–328, pp. 348–53.

X.F. Zhou, F. Fang, J.Q. Jiang, W.L. Zhu, and H.X. Xu: Mater. Sci. Techol.-Lond., 2014, vol. 30, pp. 116–22.

R. Wang, W. Zhang, Y.H. Li, D.Z. Li, Y. Kang, X.M. Yang, J. Eckert, and Z.J. Yan: Mater. Charact., 2021, vol. 171, p. 110746.

X. Zhou, M.J. Wang, Y.F. Fu, Z.X. Wang, Y.M. Li, S.K. Yang, H.C. Zhao, and H.B. Li: Mater. Charact., 2017, vol. 124, pp. 182–91.

S.J. Zheng, X.H. Yuan, X. Gong, T. Le, and A.V. Ravindra: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2342–55.

H. Feng, Z.H. Jiang, H.B. Li, W.C. Jiao, X.X. Li, H.C. Zhu, S.C. Zhang, B.B. Zhang, and M.H. Cai: Steel Res. Int., 2017, vol. 88, p. 1700149.

G.L. Ji, Q. Li, and L. Li: Mater. Sci. Eng. A., 2014, vol. 615, pp. 247–54.

Q. Zhang, Q. Li, X. Chen, J. Bao, and Z. Chen: Mater. Sci. Eng. A, 2021, vol. 826, p. 142026.

F.Y. Dong, Y. Yuan, W.D. Li, Y. Zhang, P.K. Liaw, X.G. Yuan, and H.J. Huang: Intermetallics, 2020, vol. 126, p. 106921.

K. Tang, Z.B. Zhang, J. Tian, Y.K. Wu, and F. Jiang: J. Alloys Compd., 2021, vol. 860, p. 158541.

Q.Y. Liao, Y.C. Jiang, Q.C. Le, X.R. Chen, C.L. Cheng, K. Hu, and D.D. Li: J. Mater. Sci. Technol., 2021, vol. 61, pp. 1–15.

Q.H. Zang, H.S. Yu, Y.S. Lee, M.S. Kim, and H.W. Kim: Mater. Charact., 2019, vol. 151, pp. 404–13.

L.W. Xu, H.B. Li, Z.H. Jiang, M.H. Cai, W.C. Jiao, H. Feng, S.C. Zhang, and P.C. Lu: Steel Res. Int., 2020, vol. 91, p. 2000035.

C.M. Sellars and W.J. McTegart: Acta Metall., 1966, vol. 14, pp. 1136–38.

P.R. Yang, M.H. Cai, C.F. Wu, J.H. Su, and X.P. Guo: Mater. Sci. Eng. A, 2018, vol. 729, pp. 230–40.

H. Mirzadeh, J.M. Cabrera, and A. Najafizadeh: Acta Mater., 2011, vol. 59, pp. 6441–48.

H. Mirzadeh, A. Najafizadeh, and M. Moazeny: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2950–58.

L.H. Li, F.G. Qi, Q. Wang, C.H. Hou, N. Zhao, Y. Yang, S.S. Chai, and X.P. Ouyang: Mater. Charact., 2020, vol. 169, p. 110649.

Y.S. Wu, Z. Liu, X.Z. Qin, C.S. Wang, and L.Z. Zhou: J. Alloys Compd., 2019, vol. 795, pp. 370–84.

Y.S. Lou, J.W. Yoon, H. Huh, Q. Chao, and J.H. Song: Int. J. Mech. Sci., 2018, vol. 146–147, pp. 583–601.

W.T. Jia, L.F. Ma, Q.C. Le, C.C. Zhi, and P.T. Liu: J. Alloys Compd., 2019, vol. 783, pp. 863–76.

Q.L. Pan, B. Li, Y. Wang, Y.W. Zhang, and Z.M. Yin: Mater. Sci. Eng. A, 2013, vol. 585, pp. 371–78.

Y.C. Zhu, W.D. Zeng, F.S. Zhang, Y.Q. Zhao, X.M. Zhang, and K.X. Wang: Mater. Sci. Eng. A, 2012, vol. 553, pp. 112–18.

T.V. Pirtovšek, G. Kugler, M. Godec, and M. Terčelj: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3797–808.

G.A. He, F. Liu, J.Y. Si, C. Yang, and L. Jiang: Mater. Des., 2015, vol. 87, pp. 256–65.

Y. Han, H. Wu, W. Zhang, D.N. Zou, G.W. Liu, and G.J. Qiao: Mater. Des., 2015, vol. 69, pp. 230–40.

D. Jia, W.R. Sun, D.S. Xu, and F. Liu: J. Mater. Sci. Technol., 2019, vol. 35, pp. 1851–59.

H.B. Zhang, K.F. Zhang, S.S. Jiang, H.P. Zhou, C.H. Zhao, and X.L. Yang: J. Alloys Compd., 2015, vol. 623, pp. 374–85.

J.H. Zhao, Y.L. Deng, J.G. Tang, and J. Zhang: J. Alloys Compd., 2019, vol. 809, p. 151788.

E.X. Pu, W.J. Zheng, J.Z. Xiang, Z.G. Song, and J. Li: Mater. Sci. Eng. A, 2014, vol. 598, pp. 174–82.

D.L. Zhu, M. Zhang, and Y. Wang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1662–73.

Z.J. Shao, Y. Li, B. Zhou, X.C. He, S.Z. Zhang, and L. Xu: Mater. Charact., 2020, vol. 165, p. 110376.

Y. Cao, H.S. Di, J.Q. Zhang, J.C. Zhang, T.J. Ma, and R.D.K. Misra: Mater. Sci. Eng. A, 2013, vol. 585, pp. 71–85.

D. Jia, W.R. Sun, D.S. Xu, L. Yu, X. Xin, W.H. Zhang, and F. Qi: J. Alloys Compd., 2019, vol. 787, pp. 196–205.

Y.S. Hao, J. Li, W.C. Liu, W.N. Zhang, and Z.Y. Liu: J. Iron Steel Res. Int., 2019, vol. 26, pp. 1080–87.

R.L. Goetz and S.L. Semiatin: J. Mater. Eng. Perform., 2001, vol. 10, pp. 710–17.

J.Q. Zhang, H.S. Di, X.Y. Wang, Y. Cao, J.C. Zhang, and T.J. Ma: Mater. Des., 2013, vol. 44, pp. 354–64.

S.S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah: J. Alloys Compd., 2016, vol. 681, pp. 28–42.

J.D. Robson, D.T. Henry, and B. Davis: Acta Mater., 2009, vol. 57, pp. 2739–47.

H. Yu, H.P. Sung, S.Y. Bong, M.K. Young, S.Y. Hua, and S.P. Sung: Mater. Sci. Eng. A, 2013, vol. 583, pp. 25–35.

M.Z. Bian, X.S. Huang, and Y. Chino: Acta Mater., 2021, vol. 220, p. 117328.

S.L. Liang, F. Fazeli, and H.S. Zurob: Mater. Sci. Eng. A, 2019, vol. 765, p. 138324.

P. Mannan, G. Casillas, and E.V. Pereloma: Mater. Sci. Eng. A, 2017, vol. 700, pp. 116–31.

Acknowledgments

This research was sponsored by the National Natural Science Foundation of China [Grant Nos. 51774074 and U1960203], Fundamental Research Funds for the Central Universities [Grant Nos. N2125017 and N2025014], Talent Project of Revitalizing Liaoning (Grant No. XLYC1902046), China National Postdoctoral Program for Innovative Talents [Grant No. BX20200076], and Program of Introducing Talents of Discipline to Universities (Grant No. B21001). Special thanks are due to the instrumental analysis from Analytical and Testing Centre, Northeastern University

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiao, WC., Li, HB., Feng, H. et al. High-Temperature Annealing Significantly Enhances Intrinsic Hot Workability of the As-cast High-Nitrogen M42 High-Speed Steel. Metall Mater Trans A 53, 2426–2451 (2022). https://doi.org/10.1007/s11661-022-06673-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06673-7