Abstract

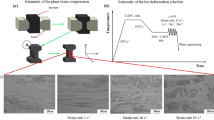

The hot compression behavior of a 17-4 PH stainless steel (AISI 630) has been investigated at temperatures of 950 °C to 1150 °C and strain rates of 10−3 to 10 s−1. Glass powder in the Rastegaev reservoirs of the specimen was used as a lubricant material. A step-by-step procedure for data analysis in the hot compression test was given. The work hardening rate analysis was performed to reveal if dynamic recrystallization (DRX) occurred. Many samples exhibited typical DRX stress-strain curves with a single peak stress followed by a gradual fall toward the steady-state stress. At low Zener–Hollomon (Z) parameter, this material showed a new DRX flow behavior, which was called multiple transient steady state (MTSS). At high Z, as a result of adiabatic deformation heating, a drop in flow stress was observed. The general constitutive equations were used to determine the hot working constants of this material. Moreover, after a critical discussion, the deformation activation energy of 17-4 PH stainless steel was determined as 337 kJ/mol.

Similar content being viewed by others

Notes

Baehr DIL-805 is a trademark of Bähr-Thermoanalyse GmbH, Hüllhorst, Germany.

References

R.A. Lula (1986) Stainless Steel, ASM, Metals Park, OH, pp. 80–86.

H. Mirzadeh and A. Najafizadeh: Mater. Chem. Phys., 2009, vol. 116, pp. 119–24.

H.J. Rack and D. Kalish: Metall. Trans., 1974, vol. 5, pp. 1595–1605.

C.N. Hsiao, C.S. Chiou, and J.R. Yang: Mater. Chem. Phys., 2002, vol. 74, pp. 134–42.

J. Wang, H. Zou, C. Li, S. Qiu, and B. Shen: Mater. Charact., 2006, vol. 57, pp. 274–80.

M. Murayama, Y. Katayama, and K. Hono: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 345–53.

K.C. Hsu and C.K. Lin: Int. J. Fatigue, 2008, vol. 30, pp. 2147–55.

S. Kundu, M. Ghosh, and S. Chatterjee: Mater. Sci. Eng. A, 2006, vol. 428, pp. 18–23.

L.W. Tsay, W.C. Lee, R.K. Shiue, and J.K. Wu: Corr. Sci., 2002, vol. 44, pp. 2101–18.

M. Esfandiari and H. Dong: Surf. Coat. Technol., 2007, vol. 202, pp. 466–78.

K.S. Raja and K. Prasad Rao (1993) J. Mater. Sci. Lett., vol. 12, pp. 957–60.

S. Isogawa, H. Yoshida, Y. Hosoi, and Y. Tozawa: J. Mater. Process. Technol., 1998, vol. 74, pp. 298–306.

AK Steel, 17-4 PH-B-08-01-07, http://www.aksteel.com, 2007.

A. Momeni, A. Shokuhfar, and S.M. Abbasi: J. Mater. Sci. Technol., 2007, vol. 23, pp. 775–78.

Aerospace Material Specification, AMS 5643Q, SAE International, Warrendale, PA, 2003.

R. Herbertz and H. Wiegels: Stahl Eisen., 1981, vol. 101, pp. 89–92.

Bähr-Thermoanalyse GmbH, http://www.baehr-thermo.de, 2008.

R. Ebrahimi and A. Najafizadeh: J. Mater. Process. Technol., 2004, vol. 152, pp. 136–43.

N.D. Ryan and H.J. McQueen: Can. Metall. Q., 1990, vol. 29, pp. 47–162.

E.I. Poliak and J.J. Jonas: Acta Mater., 1996, vol. 44, pp. 127–36.

E.I. Poliak and J.J. Jonas: ISIJ Int., 2003, vol. 43, pp. 684–91.

E.I. Poliak and J.J. Jonas: ISIJ Int., 2003, vol. 43, pp. 692–700.

A. Najafizadeh and J.J. Jonas: ISIJ Int., 2006, vol. 46, pp. 1679–84.

J.J. Jonas, X. Quelennec, L. Jiang, and E. Martin: Acta Mater., 2009, vol. 57, pp. 2748–56.

M.J. Luton and C.M. Sellars: Acta Metall., 1969, vol. 17, pp. 1033–43.

T. Sakai and J.J. Jonas: Acta Metall., 1984, vol. 32, pp. 189–209.

A. Dehghan-Manshadi and P.D. Hodgson: ISIJ Int., 2007, vol. 47, pp. 1799–803.

R.E. Reed-Hill and R. Abbaschian: Physical Metallurgy Principles, 3rd ed., PWS Publishing, Boston, MA, 1994, pp. 886–89.

M. Naderi, L. Durrenberger, A. Molinari, and W. Bleck: Mater. Sci. Eng. A, 2008, vol. 478, pp. 130–39.

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson: Mater. Sci. Eng. A, 2008, vol. 485, pp. 664–72.

F.A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman: Scripta Mater., 2007, vol. 57, pp. 759–62.

K. Lim, P.A. Manohar, D. Lee, Y.-C. Yoo, C.M. Cady, G.T. Gray, and A.D. Rollett: Mater. Sci. Forum, 2003, vols. 426–432, pp. 3903–08.

H.J. McQueen and N.D. Ryan: Mater. Sci. Eng. A, 2002, vol. 322, pp. 43–63.

H. Yang, Z.-H. Li, and Z.-L. Zhang: J. Zhejiang Univ. Sci. A, 2006, vol. 7, pp. 1453–60.

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, and K.V. Kasiviswanathan: Mater. Sci. Eng. A, 2009, vol. 500, pp. 114–21.

T. Sakai: J. Mater. Process. Technol., 1995, vol. 53, pp. 349–61.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 3, 2009.

Rights and permissions

About this article

Cite this article

Mirzadeh, H., Najafizadeh, A. & Moazeny, M. Flow Curve Analysis of 17-4 PH Stainless Steel under Hot Compression Test. Metall Mater Trans A 40, 2950–2958 (2009). https://doi.org/10.1007/s11661-009-0029-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0029-5