Abstract

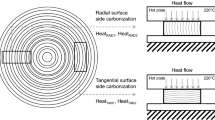

Most wooden structures for outdoor applications require repetitive maintenance operations to protect the surfaces from adverse effects of weathering. One-sided surface modification of boards with a relatively fast charring process has the potential to increase the durability and service life of wooden claddings. To assess some weathering-related effects on surface charred wood, spruce and pine sapwood were subjected to a series of long charring processes (30–120 min) at a moderate temperature of 250 °C and to a short one (30 s) at a high temperature of 400 °C. The wettability and contact angles of treated samples were investigated, and the heat transfer was measured along with the micromorphological changes taking place in the material. The result revealed an increased moisture resistance of charred spruce sapwood and an increased water uptake of pine sapwood. The contact angles of both wood species improved compared to references. Heat conduction measurement revealed that only a thin section of the wood was thermally modified. Some micromorphological changes were recorded, especially on the inside walls of the lumina. The results show that spruce sapwood has an improved resistance towards moisture-induced weathering, but more studies are needed to unlock the potential of surface charred wood.

Similar content being viewed by others

References

Gustavsson L, Joelsson A, Sathre R (2010) Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build 42:230–242. doi:10.1016/j.enbuild.2009.08.018

Werner F, Richter K (2007) Wooden building products in comparative LCA—a literature review. Int J LCA 12(7):470–479. doi:10.1065/lca2007.04.317

Buchanan AH, Levine SB (1999) Wood-based building materials and atmospheric carbon emissions. Environ Sci Policy 2:427–437. doi:10.1016/s1462-9011(99)00038-6

Schaller C, Rogez D (2007) New approaches in wood coating stabilization. J Coat Technol Res 4(4):401–409. doi:10.1007/s11998-007-9049-5

Häkkinen T, Ahola P, Vanhatalo L, Merra A (1999) Environmental impact of coated exterior wooden cladding. VTT Technical Research Centre of Finland, Building technology, 84p. http://virtual.vtt.fi/virtual/proj6/environ/env_woodclad.pdf

Hazleden DG, Morris PI (1999) Designing for durable wood construction: the 4 Ds. In: Lacasse MA, Vanier DJ (eds) Durability of building materials and components 8: service life and durability of materials and components. Institute for Research in Construction, National Research Council Canada, Ottawa, pp 734–745

Hill CAS (2006) Wood modification: chemical, thermal and other processes. John Wiley & Sons, Ltd, Chichester, UK

Jämsä S, Ahola P, Viitaniemi P (2000) Long-term natural weathering of coated ThermoWood. Pigm Resin Technol 29(2):68–74. doi:10.1108/03699420010317807

Virta J (2005) Cupping of wooden cladding boards in cyclic conditions—a study of heat-treated and non-heat-treated boards. Build Environ 40:1395–1399. doi:10.1016/j.buildenv.2004.10.014

Žlahtič M, Humar M (2017) Influence of artificial and natural weathering on the moisture dynamic of wood. BioResources 12(1):117–142

Miller H (2015) Japanese wood craftsmanship. 64p. http://www.hughmillerfurniture.co.uk/blog/japanese-wood-craftsmanship/

Kymäläinen M, Mäkelä MR, Hildén K, Kukkonen J (2015) Fungal colonisation and moisture uptake of torrefied wood, charcoal, and thermally treated pellets during storage. Eur J Wood Wood Prod 73(6):709–717. doi:10.1007/s00107-015-0950-9

Seltman J (1995) Opening the wood structure by UV-irradiation. Holz Roh Werkst 53:225–228

Wålinder M, Omidvar A, Seltman J, Segerholm K (2009) Micromorphological studies of modified wood using a surface preparation technique based on ultraviolet laser ablation. Wood Mater Sci Eng 1–2:46–51. doi:10.1080/17480270903151233

Laine K, Segerholm K, Wålinder M, Rautkari L, Ormondroyd G, Hughes M, Jones D (2014) Micromorphological studies of surface densified wood. J Mater Sci 49:2027–2034. doi:10.1007/s10853-013-7890-8

Syrjänen T (2000) Production and classification of heat treated wood in Finland, 8p. http://www.thermallytreatedwood.com/Worldwide/Finland.pdf

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Čermák P, Horáček P, Rademacher P (2014) Measured temperature and moisture profiles during thermal modification of beech (Fagus sylvatica L.) and spruce (Picea abies L. Karst.) wood. Holzforschung 68(2):173–175. doi:10.1515/hf-2013-0047

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37:109–115. doi:10.1007/s00226-003-0178-4

Hakkou M, Pétrissans ZA, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stabil 89:1–5. doi:10.1016/j.polymdegradstab.2004.10.017

Fortino S, Genoese A, Genoese A, Rautkari L (2013) FEM simulation of the hygro-thermal behaviour of wood under surface densification at high temperature. J Mater Sci 48:7603–7612. doi:10.1007/s10853-013-7577-1

Bryden KM, Ragland KW, Rutland CJ (2002) Modeling thermally thick pyrolysis of wood. Biomass Bioenergy 22:41–53. doi:10.1016/s0961-9534(01)00060-5

Rautkari L, Propezi M, Pichelin F, Hughes M (2010) Properties and set-recovery of surface densified Norway spruce and European beech. Wood Sci Technol 44:679–691. doi:10.1007/s00226-009-0291-0

Kymäläinen M, Rautkari L, Hill CAS (2015) Sorption behaviour of torrefied wood and charcoal determined by dynamic vapour sorption. J Mater Sci 50(23):7673–7680. doi:10.1007/s10853-015-9332-2

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170, 190, 210 and 230 °C. Holz Roh Werkst 64:192–197. doi:10.1007/s00107-005-0063-y

Olsson T, Megnis M, Varna J, Lindberg H (2001) Study of the transverse liquid flow paths in pine and spruce using scanning electron microscopy. J Wood Sci 47:282–288. doi:10.1007/bf00766714

Boonstra MJ, Rijsdijk JF, Sander C, Kegel E, Tjeerdsma B, Militz H et al (2006) Microstructural and physical aspects of heat treated wood. Part 1. Softwoods. Maderas Cienc Tecnol 8(3):193–208

Flaete PO, Hoibo F, Fjaertoft F, Nilsen T-N (2000) Crack formation in unfinished siding of aspen (Populus tremula L.) and Norway spruce (Picea abies L. Karst.) during accelerated weathering. Holz Roh Werkst 58:135–139. doi:10.1007/s001070050404

Belt T, Rautkari L, Laine K, Hill CAS (2013) Cupping behaviour of surface densified Scots pine wood: the effect of process parameters and correlation with density profile characteristics. J Mater Sci 48:6426–6430. doi:10.1007/s10853-013-7443-1

Acknowledgement

Financial support from the Swedish Research Council Formas (Project EnWoBio 2014-172) is greatly acknowledged by Kristina Lillqvist and Kristoffer Segerholm.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kymäläinen, M., Hautamäki, S., Lillqvist, K. et al. Surface modification of solid wood by charring. J Mater Sci 52, 6111–6119 (2017). https://doi.org/10.1007/s10853-017-0850-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0850-y