Abstract

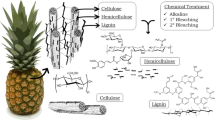

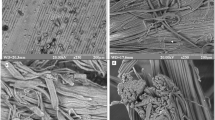

Five pulping methods using different reagents were used for the delignification of almond shells: sodium hydroxide 7.5 % v/v for 24 h at 60 °C, potassium hydroxide 7.5 % v/v for 24 h at 60 °C, formic acid/water 90/10 v/v, organosolv with ethanol/water 60/40 v/v and sodium hydroxide 15 % v/v in an autoclave for 90 min at 120 °C. The resulting cellulose pulps were evaluated using TAPPI standard methods and X-ray diffraction (XRD) to determine the lignin content and crystallinity changes. After pulping, fibers were bleached with sodium chlorite and hydrogen peroxide to obtain pure cellulose. The resulting pulps were characterized by XRD and thermogravimetry to determine the cellulose purification rates and changes in crystallinity. Then, the different pulps were acetylated, hydrolyzed and homogenized to obtain cellulose nanofibers. Nanofiber sizes were assessed by atomic force microscopy and XRD to evaluate the effect of hydrolysis on nanofibers. Finally, nanopaper sheets were produced and the properties were compared to conventional micropaper. The different treatments influenced the amount of lignin eliminated, which had a direct relationship on the subsequent bleaching treatments to obtain pure cellulose. Hence, the different chemical methods influenced the crystallinity of the fibers which also influenced the yield of cellulose nanofibers and different nanopapers.

Similar content being viewed by others

References

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues-wheat straw and soy hulls. Biores Technol 99:1664–1671

Annergren GE (1996) The properties of bleached pulp. Strength properties and characteristics of bleached chemical and mechanical pulps, in: pulp bleaching—principles and practice, section VII: the properties of bleached pulp. Tappi Press, Atlanta, pp 717–748

Arni AS, Zilli M, Converti A (2007) Solubilization of lignin components of food concern from sugar cane bagasse by alkaline hydrolysis. Cienc Technol Aliment 5:271–277

Bidlack J, Malone M, Benson R (1992) Molecular structure and component integration of secondary cell walls in plants. Proc Oklahoma Acad Sci 72:51–56

Buschle-Diller G, Inglesby MK, Wua Y (2005) Physicochemical properties of chemically and enzymatically modified cellulosic surfaces. Coll Surf 260:63–70

Charreau H, Foresti ML, Vázquez A (2013) Nanocellulose patents trends: a comprehensive review on patents on cellulose nanocrystals, microfibrillated and bacterial cellulose. Recent Pat Nanotechnol 7:56–80

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011a) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:1804–1811

Chen W, Yu H, Liu Y, Hai Y, Zhang M, Chen P (2011b) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellular 18:433–442

Dapía S, Santos V, Parajo JC (2002) Study of formic acid as an agent for biomass fractionation. Biomass Bioenerg 22:213–221

Delmer C, Amor Y (1995) Cellulose biosynthesis. Plant Cell 7(7):987–1000

Escarnota E, Aguedo M, Paquot M (2011) Characterization of hemicellulosic fractions from spelt hull extracted by different methods. Carbohyd Polym 85:419–428

Fratzl P (2003) Cellulose and collagen: from fibres to tissues. Curr Opin Coll Interface Sci 8:32–39

French A (2013) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. doi:10.1007/s10570-013-0030-4

French A, Cintrón MS (2013) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20:583–588

Gibson LJ, Ashby MF (1997) Cellular solids—structure and properties, 2nd edn. Cambridge University Press, Cambridge

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Iwamoto S, Lee S, Endo T (2014) Relationship between aspect ratio and suspensión viscosity of wood cellulose nanofibers. Polym J 46:73–76

Jonoobi M, Harun J, Shakeri A, Misra M, Oksman K (2009) Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast pulp and nanofibers. Bioresources 4:626–639

Lee SY, Chun SJ, Kang IA, Park JY (2009) Preparation of cellulose nanofibrils by high-pressure homogenizer and cellulose-based composite films. J Ind Eng Chem 15:50–55

Li R, Fei J, Cai Y, Li Y, Feng J, Yao J (2009) Cellulose whiskers extracted from mulberry: a novel biomass production. Carbohydr Polym 76:94–99

Maiti S, Jayaramudub J, Das K, Reddy SM, Sadiku R, Ray S, Liu D (2013) Preparation and characterization of nano-cellulose with new shape from different precursor. Carbohydr Polym 98:562–567

Moran J, Alvarez V, Cyras V, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellular 15:149–159

Ni Y, Van Heiningen ARP (1996) Lignin removal from Alcell® pulp by washing with ethanol and water. Tappi J 79:239–243

Pelissari F, Amaral Sobral P, Menegalli F (2014) Isolation and characterization of cellulose nanofibers from banana peels. Cellulose 21:417–432

Pirayesh H, Khazaeian A (2012) Using almond (Prunus amygdalus L.) shell as a bio-waste resource in wood based composite. Compos B 43:1475–1479

Rowell R (1983) The chemistry of solid wood in advances in chemistry series. American Chemical Society, Washington DC, pp 70–72

Sehaqui H, Liu A, Zhou Q, Berglund LA (2010) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromolecules 11:2195–2198

Serrano L, Urruzola I, Nemeth D, Belafi-Bako K, Labidi J (2011) Modified cellulose microfibrils as benzene adsorbent. Desalination 270:143–150

Sun CC (2008) Mechanism of moisture induced variations in true density and compaction properties of microcrystalline cellulose. Int J Pharm 346:93–101

Sun RC, Tomkinson J, Wang YX, Xiao B (2000) Physico-chemical and structural characterization of hemicelluloses from wheat straw by alkaline peroxide extraction. Polymer 41:2647–2656

Sun R, Sun XF, Liu GQ, Fowler P, Tomkinson J (2002) Structural and physicochemical characterization of hemicelluloses isolated by alkaline peroxide from barley straw. Polym Int 51:117–124

Sun JX, Sun XF, Zhao H, Sun RC (2004a) Isolation and characterization of cellulose 553 from sugarcane bagasse. Polym Degrad Stab 84:331–339

Sun XF, Sun RC, Fowler P, Baird MS (2004b) Isolation and characterization of cellulose obtained by a two-stage treatment with organosolv and cyanamide activated hydrogen peroxide from wheat straw. Carbohydr Polym 55:379–391

TAPPI (2007) TAPPI Standards, in TAPPI test methods, Atlanta, GA, USA

Urruzola I, de Andres MA, Nemeth D, Belafi-Bako K, Labidi J (2013a) Multicomponents adsorption of modified cellulose microfibrils. Desalin Water Treat 51:10–12

Urruzola I, Serrano L, Llano-Ponte R, Andrés MA, Labidi J (2013b) Obtaining of eucalyptus microfibrils for adsorption of aromatic compounds in aqueous solution. Chem Eng J 229:42–49

Vincent JF (1999) From cellulose to cell. J Exp Biol 202:3263–3268

Wang B, Sain K, Oksman M (2007) Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl Compos Mater 14:89–103

Yousefi H, Hejazi S, Mousavi M, Azusa Y, Heidari AH (2013) Comparative study of paper and nanopaper properties prepared from bacterial cellulose nanofibers and fibers/ground cellulose nanofibers of canola straw. Ind Crop Prod 43:732–737

Yuan J, Yu Y, Wang Q, Fan X, Chen S, Wang P (2013) Modification of ramie with 1-butyl-3-methylimidazolium chloride ionic liquid. Fiber Polym 14:1254–1260

Zuluaga R, Mondragon I, Gañan P (2009) New approaches to cellulose microfibril isolation from Musaceae agro-industrial residues. Compos Interface 16:27–37

Acknowledgments

The authors would like to thank the the Department of Education, Universities and Investigation of the Basque Government (IT672-13) for financially supporting this work. E. Robles would like to acknowledge the financial support of CONACyT, Mexico through scholarship No. 216178. The authors would like to thank Dr. Alfred D. French for the valuable advices for the preparation of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Urruzola, I., Robles, E., Serrano, L. et al. Nanopaper from almond (Prunus dulcis) shell. Cellulose 21, 1619–1629 (2014). https://doi.org/10.1007/s10570-014-0238-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0238-y