Abstract

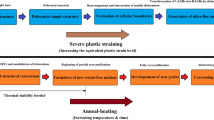

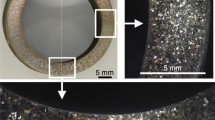

A universal scaling of subgrain size evolution in face-centered cubic (fcc) metals with moderate to high stacking fault energy is proposed for a class of deformation processing applications based on severe plastic deformation inherent to chip formation in Plane Strain Machining (PSM). The complex trajectories of grain refinement followed by PSM are captured using two parameters — the effective strain and the parameter “R” that is a function of the strain-rate, temperature and material dependent constants. Proposed parameterization entails a weak contribution of strain and “R” interaction which enables examining the athermal evolution of subgrain size. This approach yields that the subgrain size behavior, under the PSM thermomechanical conditions, obeys a universal scaling law while scanning along the strain levels.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

S. Abolghasem, S. Basu, S. Shekhar, J. Cai, and M.R. Shankar, “Mapping Subgrain Sizes Resulting from Severe Simple Shear Deformation,” Acta Meterialia, 60(2012), 376–386.

R. Humphreys, F.J. Humphreys, and M. Hatherly, Recrystallization and Related Annealing Phenomena (London: Elsevier science Ltd., 2002).

E. Nes, “Modeling of Work Hardening and Stress Saturation in FCC Metals,” Progress in Materials Science, 41(1998),129–193.

B. Tolaminejad, F. Brisset, and T. Baudin, “EBSD study of the micro structure evolution in a commercially pure aluminium severely deformed by ECAP,” Materials Science and Engineering, 32 (2012) 012025–012026.

A.P. Zhilyaev, B.K. Kim, J.A. Szpuna, M.D. Baro, T.G. Langdon, “The microstructural characteristics of ultrafine-grained nickel,” Materials Science Engineering, 391(2005) 377–389.

Y. Amouyal, S.V. Divinski, L. Klinger, and E. Rabkin, “Grain boundary diffusion and recrystallization in ultrafine grain copper produced by equal channel angular pressing,” Acta Meterialia, 56 (2008), 5500–5513.

W. Moscoso, M. Ravi Shankar, J. B. Mann, W. D. Compton and S. Chandrasekar, “Bulk Nanostructured Materials by Large Strain Extrusion Machining (LSEM)”, Journal of Materials Research, 22(1) (2007), 201–205.

K.V. Jata, S.L. Semiatin, “Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys,” Scripta Materialia, 43(2000), 743–749.

S. Shekhar, S. Abolghasem, S. Basu, J. Cai, and M.R. Shankar, “Effect of Severe Plastic Deformation in Machining Elucidated via Rate-Strain-Microstructure (RSM) Mappings,” ASME Journal of Manufacturing Science and Engineering, 134(2012), 0310081–03100811.

S. Abolghasem, S. Basu, S. Shekhar, J. Cai, M.R. Shankar, “Quantifying the Progression of Dynamic Recrystallization in Severe Plastic Deformation at High Strain Rates,” Journal of Materials Research, 28(2013), 2056–2069.

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2015 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Abolghasem, S., Shankar, R., Akhavan-Tabatabaei, R., Zarama, R. (2015). Universal Scaling Behaviour of Subgrain Size Evolution in Face-Centered Cubic Metals With Moderate to High Stacking Fault Energy. In: TMS 2015 144th Annual Meeting & Exhibition. Springer, Cham. https://doi.org/10.1007/978-3-319-48127-2_174

Download citation

DOI: https://doi.org/10.1007/978-3-319-48127-2_174

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48608-6

Online ISBN: 978-3-319-48127-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)