Abstract

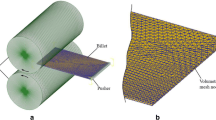

The physical simulation of sheet billet formation in the course of ingotless metal rolling has been performed. Parameters for controlling the processes of crystallization and the formation of the structure of such billets have been theoretically determined. The regularities of melt hydrodynamics in the interroll space and metal casting conditions of (overheating temperature, heat removal rate, etc.) affecting the mentioned processes have been established. By using a transparent organic alloy (camphene), an effect of heat-and-mass transfer processes in a roller mold exerted on the formation of the sheet billet structure in the course of ingotless metal rolling has been demonstrated. The transformation of the coarse primary structure of crusts solidifying on the rolls into a fine-grained structure (close to strained one) when the billet exits the rolling zone is clearly shown. An interrelation between the linear casting velocity of the model alloy and the overheating temperature of the melt and the heat removal rate from the mold rolls has been revealed. At the same time, specific values of parameters that guarantee the stability of the roll casting process are determined. Based on the obtained results, practical recommendations for the conditions of roll casting of real metals including steels have been proposed.

Similar content being viewed by others

REFERENCES

Efimov, V.A and El’darkhanov, A.S., Tekhnologii sovremennoi metallurgii (Technologies of Modern Metallurgy), Moscow: Novye Tekhnologii, 2004.

Ovsienko, D.E., Zarozhdenie i rost kristallov iz rasplava (Initiation and Growth of Crystals from Melt), Kiev: Naukova Dumka, 1994.

Chalmers, B., Principles of Solidification, New York: John Wiley & Sons, 1964.

Balandin, G.F., Formirovanie kristallicheskogo stroeniya otlivok (Formation of Crystal Structure of Castings), Moscow: Mashinostroenie, 1979.

Flemings, M.C., Solidification Processing, New York: McGraw-Hill, 1974.

Nuradinov, A.S. and Nakhaev, M.R., Protsessy kristallizatsii i formirovaniya struktury litykh zagotovok, Groznyi: Chechenskii Gos. Univ., 2020.

El’darkhanov, A.S., Efimov, V.A., and Nuradinov, A.S., Protsessy formirovaniya otlivok i ikh modelirovanie (Formation of Castings and Its Modeling), Moscow: Mashinostroenie, 2001.

Brovman, M.Ya., Nikolaev, V.A., and Polukhin, V.P., Plastic-deformation zone length and the allowable speed for ingotless rolling, Russ. Metall., 2007, vol. 2007, no. 1, pp. 36–40. https://doi.org/10.1134/S0036029507010089

Brovman, M.Ya., Nikolaev, V.A., and Polukhin, V.P., Temperature mode analysis and increasing the efficiency of shaft and roll cooling, Proizvod. Prokata, 2007, no. 7, pp. 36–43.

Kawalla, R., Ullmann, M., Schmidt, Ch., Dembińska, J., and Vogt, H.P., Properties of magnesium strips produced by twin-roll-casting and hot rolling, Mater. Sci. Forum, 2011, vol. 690, pp. 21–24. https://doi.org/10.4028/www.scientific.net/MSF.690.21

Efimov, V.A., Anisovich, G.A., Babich, V.N., et al., Spetsial’nye sposoby lit’ya. Spravochnik (Special Approaches of Casting: Reference Book), Moscow: Mashinostroenie, 1991.

Brovman, M.Ya. and Nikolaev, V.A., On the improvement of quality of band surface at rolling in rolling combined aggregates, Proizvod. Prokata, 2006, no. 5, pp. 9–14.

Shur, I.A., Prospects of development of ingotless rolling of aluminum alloys, Tekhnol. Legkikh Splavov, 2001, nos. 5–6, pp. 38–41.

Büchner, A.R., Thin strip casting of steel with a twin roll caster-correlation between feeding system and strip quality, Steel Res. Int., 2004, vol. 75, no. 1, pp. 5–12. https://doi.org/10.1002/srin.200405919

Kats, A.M., Kudin, M.V., and Shatalov, R.L., Research of heat transfer and solidification at ingotless rolling of low-alloyed zinc, Tsvetn. Metall., 2002, no. 9, pp. 80–85.

Nuradinov, A.S., Nogovitsyn, A.V., Nuradinov, I.A., et al., Research of possibility of control of the formation of crystal structure of metal alloys, Sci. Innovation, 2020, no. 4, pp. 67–73.

Eldarkhanov, A.S., Nuradinov, A.S., Uzdieva, N.S., and Nuradinov, I.A., Optimization of thermal performance of CCM mold, Metallurgist, 2019, vol. 63, no. 1, pp. 11–20. https://doi.org/10.1007/s11015-019-00789-9

El’darkhanov, A.S., Nuradinov, A.S., Uzdieva, N.S., Akhtaev, S.S.-S., and Nuradinov, I.A., Control of heat exchange processes in the roll mould in non-ingot rolling, Stal’, 2022, no. 4, pp. 7–11.

El’darkhanov, A.S., Nuradinov, A.S., Kondrat’ev, Yu.I., and Nuradinov, I.A., Formation of structure and properties of aluminum alloys during roll casting, Metallurgist, 2022, vol. 66, nos. 1–2, pp. 130–138. https://doi.org/10.1007/s11015-022-01308-z

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

About this article

Cite this article

Nuradinov, A.S., Eldarkhanov, A.S., Uzdieva, N.S. et al. Physical Simulation of Sheet Billet Formation under Ingotless Metal Rolling. Steel Transl. 52, 677–682 (2022). https://doi.org/10.3103/S0967091222070142

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222070142