Abstract

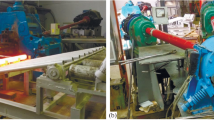

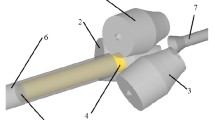

In the continuous casting of steel ingots, the most significant trend over the last few decades has been the partial transfer of deformation processes from the region of complete solidification (the rolling mill) to the region characterized by a two-phase solid–liquid state (the continuous-casting line). However, such two-stage deformation of the continuous-cast ingot entails changes in the physical modeling of the behavior of surface and interior defects in subsequent rolling. In particular, modifications are required in selecting the geometry and spatial orientation of the defects. In the present work, the influence of the surface-defect orientation and central macrostructure (pore content) of bar billet deformed in the continuous-casting line is investigated by means of laminar physical models. The deformation conditions of reduced-scale (1: 5) continuous- cast billet are studied experimentally in two rolling configurations: (1) the use of smooth rollers to simulate groove-free rolling in the first two stands of the cogging group in the 350 continuous medium-bar mill; (2) rolling in the first and second pairs of straight grooves in the cogging stand of the 500/370 mill at PAO Donetskii Metallurgicheskii Zavod. Since this is a multivariant problem, a universal design has been developed for the physical model, so as to simulate the spatial configuration of both surface and internal defects. The research shows that, in rolling the physical models with an extension coefficient greater than 2.0 and practically 60° inclination of the simulated defects to the rolling axis, their complete elimination is possible. In turn, decreasing the inclination to 30° facilitates greater extension of the simulated defects and only slightly reduces their width. When the inclination of the simulated defects to the rolling axis is 90° (complete lack of coaxiality), broadening of the defects and their compression to the initial length is only observed after 90° rotation. The experimental data provide insights regarding the elimination of internal defects (pores) in the metal as a function of the total extension, the inclination of the defects’ longitudinal axis to the rolling direction, and their distance from the longitudinal–transverse symmetry plane.

Similar content being viewed by others

References

Tarmann, B. and von Baar, H., AIMI. Born, Steel Contin. Process., 1966, vol. 21, p. 361.

Thome R., Ostheimer V., Ney G., et al., Soft reduction of continuous cast billets at Saarstahl, MPT, Metall. Plant Technol. Int., 2007, vol. 30, no. 1, pp. 112–118.

Vasilev, Ya.D. and Minaev, A.A., Teoriya prodol’noi prokatki (Theory of Longitudinal Rolling), Donetsk: Unitekh, 2009.

Pogorzhel’skii, V.I., Kontroliruemaya prokatka nepreryvnolitogo metalla (Controlled Rolling of Continuously Casted Metal), Moscow: Metallurgiya, 1986.

Saiga, I., Fukuy, K., Punakisiy, Y., et al., The quality of the ingots obtained by combining continuous casting and rolling, Tetsu-To-Hagane, 1974, vol. 60, no. 7, pp. 990–999.

Peretyat’ko, V.N., Mart’yanov, Yu.A., Umanskii, A.A., and Fedorov, A.A., Distortion of longitudinal dtfects in rolling on a continuous small-bar mill, Steel Transl., 2008, vol. 38, no. 8, pp. 599–602.

Smirnov, Y. and Sklyar, V., Features of deformation of partly crystallization blooms at their two-stage soft reduction, Mater. Sci. Forum, 2012, vols. 704–705, pp. 1–5.

Lubenets, A.N., Smirnov, E.N., and Shcherbachev, V.V., Production of ship sections from continuous casting billets, Stal’, 2002, no. 8, pp. 102–106.

Smirnov, A.N., Khobta, A.S., Serov, A.I., et al., Casting of steel from the tundish of a continuous caster with a sliding gate, Russ. Metall. (Engl. Transl.), 2012, vol. 2012, no. 12, pp. 1–5.

Cabai, G. and Cabai, F., Continuous Casting of Steel. Some Principles and Practical Notes, Boston: STS, 2010.

Smyrnov, Y.N., Skliar, V.A., Belevitin, V.A, Shmyglya, R.A., and Smyrnov, O.Y., Defect healing in the axial zone of continuous-cast billet, Steel Transl., 2016, vol. 46, no. 5, pp. 325–328.

Smirnov, E.N., Serov, A.I., Sklyar, V.A., et al., Analysis of the quality of continuous cast steel billets of steel 45 and U7 steel, Trudy konferentsii “Problemy chernoi metallurgii–2015” (Proc. Conf. “Problems of Ferrous Metallurgy–2015”), Cherepovets: Cherepov. Gos. Univ., 2016, pp. 40–47.

Kandaurov, L.E., Nikiforov, B.A., Morozov, A.A., et al., Beskalibrovaya prokatka sortovykh profilei (Groovelles Rolling of Section Bars), Magnitogorsk: Magn. Dom Pechati, 1998.

Janadzava, T., Tanaka, T., Noda, A., et al., Development of groovelles rolling, Trans. Iron Steel Inst. Jpn., 1983, vol. 22, no. 8, pp. 710–715.

Krakht, V.B., Pratusevich, A.E., and Shlyakhov, N.A., Improving the efficiency of products of small-mediumsection mill 350 at Oskol Electrometallurgical Plant, Proizvod. Prokata, 2003, no. 5, pp. 19–21.

Tarnovskii, I.Ya., Pozdeev, A.A., and Lyashkov, V.B., Deformatsiya metalla pri prokatke (Metal Deformation during Rolling), Sverdlovsk: Metallurgizdat, 1956.

Loginov, Yu.N. and Eremeeva, K.V., Rolling of the billet with a single pore located in the metal volume, Zagotovitel’noe Proizvod. Mashinostr., 2009, no. 11, pp. 33–37.

Zil’berg, Yu.V., The study of regularities of forming of surface defects at rolling, Stal’, 1997, no. 10, pp. 44–46.

Peretyat’ko, V.N., Rogov, Yu.E., Zhuravlev, B.K., and Nefedov, V.M., The development of surface defects in box passes, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2011, no. 2, pp. 26–29.

Utkin, G.S., Rezvov, B.S., Khramtsov, V.V., et al., Intensification of the generation of surface defects at billets production, Proizvod. Prokata, 2003, no. 4, pp. 10–20.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.N. Smirnov, V.A. Sklyar, O.E. Smirnov, V.A. Belevitin, R.E. Pivovarov, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2018, No. 5, pp. 399–406.

About this article

Cite this article

Smirnov, E.N., Sklyar, V.A., Smirnov, O.E. et al. Behavior of Structural Defects of Already-Deformed Continuous-Cast Bar on Rolling. Steel Transl. 48, 289–295 (2018). https://doi.org/10.3103/S0967091218050091

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218050091