Abstract

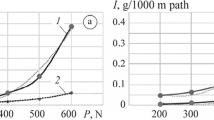

The results of hardness tests of a sample of a gear wheel made of 14KhN3MA steel, which has passed a full cycle of chemical-thermal treatment (carburization, hardening, low tempering), are presented. The hardness was measured using Vickers method at an indenter load of 1.961 N and 4.903 N at different distances from the sample surface. It is established that the results of hardness tests at load of 1.961 N have a greater scatter of hardness values than with load of 4.903 N. It is shown that increasing of the scatter of measurement results with lower load is due to structural inhomogeneity (banding) of the sample. An approximating dependence was obtained between hardness HV0.2 and hardness measured during tests with load of 4.903 N, which promotes increasing of hardness measurement accuracy of surface-strengthened steel products.

Similar content being viewed by others

REFERENCES

GOST R (State Standard) ISO 6507-1–2007: Metallic materials. Vickers hardness test. Par 1: Test method (IDT), 2008.

GOST R (State Standard) ISO 6507-1–2007: Metals and alloys. Vickers hardness test. Part 4: Tables of hardness values (IDT), 2010.

Grigorovich, V.K., Tverdost’ i mikrotverdost’ metallov (Hardness and Microhardness of Metals), Moscow: Nauka, 1976.

Gerberich, W.W., Tymiak, N.I., Grunlan, J.C., Horstemeyer, M.F., and Baskes, M.I., Interpretations of indentation size effects, J. Appl. Mech., 2002, vol. 69, pp. 433–442. https://doi.org/10.1115/1.1469004

Adaskin, A.M. and Sapronov, I.Yu., Relationship between macro- and microhardness of materials at indentation by Vickers pyramid, Uprochnyayushchie Tekhnol. Pokrytiya, 2018, vol. 14, no. 11, pp. 489–495.

Bykov, Yu.A., Karpukhin, S.D., Panfilov, Yu.V., et al., Measurement of hardness of thin films, Metalloved. Term. Obrab. Met., 2003, no. 10, pp. 32–35.

Golovin, Yu.I., Nanoindentation as a tool for complex assessment of physicomechanical properties of materials in submicrovolumes, Zavod. Lab., Diagn. Mater., 2009, vol. 75, no. 1, pp. 45–58.

Rudenko, S.P., Calculation of the lifetime of high-loaded gears of car transmissions taking into account the quality of chemical-thermal hardening, Mekh. Mash., Mekhanismov Mater., 2010, no. 4, pp. 58–60.

Rudenko, S.P. and Val’ko, A.L., Peculiarities of deep contact resistance analysis of gears of car transmissions, Vestn. Mashinostr., 2015, no. 11, pp. 5–7.

Val’ko, A.L., Rudenko, S.P., Mosunov, E.I., and Mikhlyuk, A.I., RB Patent 15273, 2011.

Glazov, V.M. and Vigdorovich, V.N., Mikrotverdost’ metallov (Microhardness of Metals), Moscow: Metallurgizdat, 1961.

Belinkii, A.L., Bulgakov, V.A., Goryushin, V.V., et al., Kontrol’ kachestva termicheskoi obrabotki stal’nykh polufabrikatov i detalei. Spravochnik (Quality Inspection of Heat Treatment of Steel Semiproducts and Machine Elements: Reference Book), Kal’ner, V.D., Ed., Moscow: Mashinostroenie, 1984.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Gumerov

About this article

Cite this article

Valko, A.L., Rudenko, S.P. & Sandomirskii, S.G. Increasing the Accuracy of Measuring the Hardness of Surface-Hardened Steel Products. Steel Transl. 52, 633–637 (2022). https://doi.org/10.3103/S0967091222060158

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222060158