Abstract

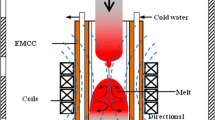

An analysis of the magnetization and heating of a ferromagnetic charge in the crucibles of two types of induction furnaces is given. In induction furnaces, the charge is magnetized by a vertical electromagnetic flux, and in electromagnetic furnaces with a curved U, C or O-shaped magnetic circuit (MCR)—by a horizontal flux. Insufficient knowledge of these largely general processes of magnetization is shown. The importance of the magnetic induction Bi in the charge material is reflected. Difficulties in determining this parameter during the magnetization of a single piece of the charge and other magnetic quantities associated with it are revealed: induction Bm and strength Hm of the demagnetizing field, demagnetization coefficient N, magnetization M, magnetic permeability of the substance μi and body μb, susceptibility km, etc. Difficulties increase with magnetization of charge, which is a porous body with a crucible volume Vb and a filling factor \({{K}_{v}}\) ≤ 0.5 of this volume with ferromagnetic pieces. It also creates a demagnetizing field with induction Bmpb and strength Hmpb. In addition, the pores have an additional demagnetizing effect. Therefore, the induction Bipb in a porous body is less than the induction Bi in a solid one. To compare the magnetization of a ferromagnetic charge by horizontal and vertical flows with a frequency of 50 Hz, modeling experiments were carried out with samples of unconsolidated shot DSL 08 made of high-carbon steel (GOST 11964–83) with \({{K}_{v}}\) ≈ 0.53. The samples were placed in an inductor and between the poles of a U-shaped magnetic circuit. The induction was measured with cylindrical and flat probes of a Sh115 milliteslameter in air and in a sample. An advantage of the electromagnetic furnace over the induction one in a more uniform distribution of induction Вi in the charge and its significant excess by 1.7 times over the induction Be in the working cavity of the furnace was found, which indicates a more efficient use of electromagnetic energy in this furnace during heating. It is proposed to control the induction Вi when the charge is heated by the method of an ammeter-voltmeter using a measuring coil made of heat-resistant wire.

Similar content being viewed by others

Notes

This work was carried out with the participation of R.M. Gainulin, and P.A. Navalikhin.

REFERENCES

Mühlbauer, A., History of Induction Heating and Melting, Essen: Vulkan-Verlag, 2008.

Levshin, G.E., High-tech technologies of induction melting in inductor and electromagnetic crucible furnaces, Naukoemkie Tekhnol. Mashinostr., 2016, no. 3, pp. 12–21.

Farbman, S.A. and Kolobnev, I.F., Induction Furnaces for Melting Metals and Alloys, Moscow: Metallurgiya, 1968.

Brokmeier, K.-H., Induktives Schmelzen, Essen: W. Girardet, 1966.

Egorov, A.V. and Morzhin, A.F., Elektricheskie pechi (Electric Furnaces), Moscow: Metallurgiya, 1975.

Romanov, L.M., Boldin, A.N., Grablev, A.N., and Mikhailov, D.P., Elektricheskie pechi dlya vyplavki chernykh i tsvetnykh splavov (Electric Furnaces for Ferrous and Non-Ferrous Alloys Smelting), Moscow: Mosk. Gos. Industrial’nyi Univ., 2007.

Modern melting units, in Sb. ITTsM Metallurg (Collection of Papers of ITsTM Metallurg), Moscow: Metallurg-Consulting, 2014.

Levshin, G.E., Determination of magnetic induction of a crucible furnace inductor, Polzunovskii Al’m., 2016, no. 4, pp. 131–136.

Rudnev, V., Loveless, D., and Cook, R.L., Handbook of Induction Heating, New York: CRC Press, 2017. https://doi.org/10.1201/9781315117485%20

Levshin, G.E., The magnetic permeability of a magnetized “ferromagnetic material–air” two-phase dispersed system, Electr. Technol. Russ., 2002, no. 1, pp. 52–62.

Levshin, G.E., Demagnetizing effect of a dispersed medium, Electr. Technol. 1997, no. 2, pp. 103–109.

Kuvaldin, A., Fedin, M., and Generalov, I., Determination electrical parameters lumpy ferro-magnetic charge when heated to the Curie point, Acta Tech. CSAV (Ceskoslovensk Akad. Ved), 2017, vol. 62, no. 1, pp. 85–92.

Bay, F., Labbe, V., Favennec, Y., and Chenot, J.L., A numerical model for induction heating processes coupling electromagnetism and thermomechanics, Int. J. Numer. Methods Eng., 2003, vol. 58, no. 6, pp. 839–867. https://doi.org/10.1002/nme.796%20

Drobenko, B., Hachkevych, O., and Kournyts’kyi, T., Thermomechanical behavior of polarizable and magnetizable electroconductive solids subjected to induction heating, J. Eng. Math., 2008, vol. 61, nos. 2–4, pp. 249–269. https://doi.org/10.1007/s10665-008-9216-4

Glebov, A.O., Karpov, S.V., Karpushkin, S.V., and Malygin, E.N., Modeling the induction heating of press equipment in an automatic-temperature-control mode, J. Eng. Phys. Thermophys., 2019, vol. 92, no. 5, pp. 1130–1141. https://doi.org/10.1007/s10891-019-02028-z

Kurek, K. and Lochina, W., Controlling the continuous induction heating process of the ferromagnetic charge, in Electromagnetic Fields in Electrical Engineering, Studies in Applied Electromagnetics and Mechanics, vol. 22, 2002, pp. 462–467.

Di Luozzo, N., Fontana, M., and Arcondo, B., Modelling of induction heating of carbon steel tubes: Mathematical analysis, numerical simulation and validation, J. Alloys Compd., 2012, vol. 536, pp. S564–S568. https://doi.org/10.1016/j.jallcom.2011.12.084

Zabett, A., Mohamadi Azghandi, S.H., Simulation of induction tempering process of carbon steel using finite element method, Mater. Des., 2012, vol. 36, pp. 415–420. https://doi.org/10.1016/j.matdes.2011.10.052

Kuvaldin, A.B., Fedin, M.A., and Generalov, I.M., Physical model for definition of characteristics of the induction crucible furnace when heating ferromagnetic lumpy charge, J. Induct. Heat., 2015, no. 1, pp. 3–8.

Levshin, G.E., Determination of induction in EMF-5.7-60M electromagnetic furnace by ammeter-voltmeter method, Polzunovskii Al’m., 2016, no. 4, pp. 85–88.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares that he has no conflicts of interest.

Additional information

Translated by V. Selikhanovich

About this article

Cite this article

Levshin, G.E. Magnetization of a Ferromagnetic Charge during Induction Heating. Steel Transl. 52, 134–139 (2022). https://doi.org/10.3103/S0967091222020115

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222020115