Abstract

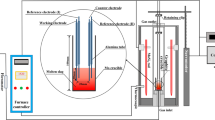

The electromagnetic cold crucible (EMCC) technique is an effective method to melt and directionally solidify reactive and high-temperature materials without contamination. The temperature field and fluid flow induced by the electromagnetic field are very important for melting and controlling the microstructure. In this article, a 3D EMCC model for calculating the magnetic field in the charges (TiAl alloys) using the T-Ω finite element method was established and verified. Magnetic fields in the charge under different electrical parameters, positions and dimensions of the charge were calculated and analyzed. The calculated results show that the magnetic field concentrates in the skin layer, and the magnetic flux density (B) increases with increasing of the frequency, charge diameter and current. The maximum B in the charge is affected by the position of the charge in EMCC (h 1) and the charge height (h 2), which emerges at the middle of coils (h c) when the relationship of h c < h 1 + h 2 < h c + δ is satisfied. Lower frequency and smaller charge diameter can improve the uniformity of the magnetic field in the charge. Consequently, the induced uniform electromagnetic stirring weakens the turbulence and improves temperature uniformity in the vicinity of the solid/liquid (S/L) interface, which is beneficial to forming a planar S/L interface during directional solidification. Based on the above conclusions, the TiAlNb alloy was successfully melted with lower power consumption and directionally solidified by the square EMCC.

Similar content being viewed by others

References

B. Liu, Y. Liu, C.Z. Qiu, C.X. Zhou, J.B. Li, H.Z. Li and Y.H. He: J. Alloy. Compd., 2015, vol. 640, pp. 298-304.

L. Yu, X.P. Song, L. You, Z.H. Jiao and H.C. Yu: Scri. Mater., 2015, vol.109, pp. 61-63.

K.P. Rao, Y.V.R.K. Prasad and K. Suresh: Mater. Design., 2011, vol. 32, pp. 4874-4881.

K. Edalati, S. Toh, H. Iwaoka, M. Watanabe, Z. Horita, D. Kashioka, K. Kishida and H. Inui: Scri. Mater., 2012, vol. 67, pp. 814-817.

X. Wu: Intermetallics, 2006, vol. 14, pp. 1114-1122.

K. Gebauer: Intermetallics, 2006, vol. 14, pp. 355-360.

M. Takeyama and S. Kobayashi: Intermetallics, 2005, vol. 13, pp. 993-999.

X.Y. Gu, P.D. Han, C.L. Zhang, Z.Y. He, M.H. Dong, J.X. Xue and Y.P. Liu: Rare. Metal. Mat. Eng., 2012, vol. 41, pp. 437-441.

T. Tetsui, T. Kobayashi, T. Ueno and H. Harada: Intermetallics, 2012, vol. 31, pp. 274-281.

J. Lapin, Z. Gabalcová and T. Pelachová: Intermetallics, 2011, vol. 19, pp. 396-403.

J. Lapin, L. Ondrúš and O. Bajana: Mater. Sci. Eng. A, 2003, vol. 360, pp. 85-95.

Q.Y. Xu, H. Zhang, X. Qi and B.C. Liu: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 555–561.

H. Saari, J. Beddoes, D.Y. Seo and L. Zhao: Intermetallics, 2005, vol. 13, pp. 937-943.

S. Sarkar, V. Singh, S.K. Ajmani, R. Ranjan and K. Rajasekar: ISIJ. Int., 2016, vol. 56, pp. 2181-2190.

H.J. Choe, T. Teral, I. Miyazaki, S. Yamamoto, M. Yonemura, T. Fukuda and T. Kakeshita: ISIJ. Int., 2016, vol. 56, pp. 1652-1655.

W.D. Xuan, H. Liu, J. Lan, C.J. Li, Y.B. Zhong, G.H. Cao and Z.M. Ren: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3231-3236.

J.B. Yu, D.F. Du, Z.M. Ren, Y. Fautrelle, R. Moreau and X. Li: ISIJ. Int., 2017, vol. 57, pp. 337-342.

M. Ščepanskis, M. Sarma, P. Vontobel, P. Trtik, K. Thomsen, A, Jakovičs and T. Beinerts: Metall. Mater. Trans. B, 2017, vol. 48, pp. 1045-1054.

R.R. Chen, S.L. Dong, J.J. Guo, H.S. Ding, Y.Q. Su and H.Z. Fu: Mater. Design., 2015, vol. 89, pp. 492-506.

R.R. Chen, S.L. Dong, J.J. Guo, H.S. Ding, Y.Q. Su and H.Z. Fu: J. Alloy. Compd., 2015, vol. 648, pp. 667-675.

H. Kubota, A. Tomizawa, K. Yamamoto, N. Okada, T. Hama and H. Takuda: ISIJ. Int., 2014, vol. 54, pp. 1856-1865.

M. Pokusova and M. Muragas: ISIJ. Int., 2015, vol. 55, pp. 1669-1676.

L. Feng and W.Y. Shi: ISIJ. Int., 2016, vol. 56, pp. 50-56.

J. Zeng, W.Q. Chen, S.L. Zhang, Y. Li and Q.L. Wang: ISIJ. Int., 2015, vol. 55, pp. 2142-2149.

A. Kao, P.D. Lee and K. Pericleous: ISIJ. Int., 2014, vol. 54, pp. 1283-1287.

Z.Y. Lu, Y.K. Zhang, Z.M. Ren, Y. Fautrelle and X. Li: ISIJ. Int., 2017, vol. 57, pp. 84-90.

J.R. Yang, R.R. Chen, H.S. Ding, J.J. Guo, Y.Q. Su and H.Z. Fu: J. Mater. Process. Tech., 2013, vol. 213, pp. 1355-1363.

A. Kartavykh, V. Ginkin, S. Ganina, S. Rex, U. Hecht, B. Schmitz and D. Voss: Intermetallics, 2011, vol. 19, pp. 769-775.

A. Umbrashko, E. Baake, and B. Nacke: Compel, 2005, vol. 24, pp. 314-323.

H.T. Bui, S.J. Hwang: Int. J. Heat Mass Transfer, 2015, vol. 86, pp. 16-30.

Y. Cho, Y. Oh, K. Yi, S. Chung and J. Shim: Model. Simul. Mater. Sc, 1996, vol. 4, pp. 11-22.

F. Bioul and F. Dupret: IEEE. Trans. Magn., 2005, vol. 41, pp. 2496-2505.

R.R. Chen, J.R. Yang, H.S. Ding, F. Huang, Y.Q. Su, J.J. Guo and H. Z. Fu: T. Nonferr. Metal. Soc., 2012, vol. 22, pp. 404-410.

R.R. Chen, J.R. Yang, F. Huang, Y.Q. Su, J.J. Guo and H.Z. Fu: China. Foundry, 2012, vol. 9, pp. 15-19.

R.R. Chen, J.R. Yang, H.S. Ding, F. Huang, Y.Q. Su, J.J. Guo and H.Z. Fu: J. Mater. Process. Tech., 2012, vol. 212, pp. 1934-1940.

J.R. Yang, R.R. Chen, H.S. Ding, Y.Q. Su, J.J. Guo, F. Huang and H.Z. Fu: Compel, 2013, vol. 32, pp. 997-1008.

J.R. Yang, R.R. Chen, J.J. Guo and H.Z. Fu: Int. J. Heat Mass Transfer, 2016, vol. 100, pp. 131-138.

L. Feng and W.Y. Shi: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1895-1901.

C.J. Carpenter: IEE. P-Elect. Power. Appl., 1980, vol. 124, pp. 1026-1034.

J.P. Webb and B. Forghani: IEEE. Trans. Magn., 1993, vol. 29, pp. 2461-2463.

J. Kumbernuss, C. Jian, J.H. Wang, H.X. Yang and W.N. Fu: Appl. Energ., 2012, vol. 90, pp. 148-153.

J. Lee, D.M. Matson, S. Binder, M. Kolbe, D. Herlach, and R.W. Hyers: Metall. Mater. Trans. B, 2013, vol. 45B, pp. 1018-1023.

J. Lee, X. Xiao, D.M. Matson, and R.W. Hyers: Metall. Mater. Trans. B, 2014, vol. 46B, pp. 199-207.

E. Westphal, A. Muiznieks and A. Muhlbauer: IEEE. Trans. Magn., 1996, vol. 32, pp. 1601-1604.

S.C. Chu, S.S. Lian and F.K. Chen: Acta Metall. Sin., 2004, vol. 266, pp. 229-237.

D. Jiang and M. Zhu: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3446-3458.

D.B. Jiang and M.Y. Zhu: Metall. Mater. Trans. B, 2017, vol. 48, pp. 444-455.

W. Assmus, C. Gross, A. Muiznieks, G. Raming, A. Muhlbauer and C. Stenzel: Cryst. Res. Technol., 1999, vol. 34, pp. 319-328.

L.N.W. Damoah, L.F. Zhang, High-frequency electromagnetic purification of silicon, Metall. Mater. Trans. B, 2015, vol. 46, pp. 2514-2528.

A. Widjaja, A. Needleman and E. Giessen: Model. Simul. Mater. Sc., 1998, vol. 3, pp. 473-484.

P.A. Davidson: An Introduction to Magnetohydrodynamics, Cambridge University Press, New York, 2001, pp. 393.

A.V. Kartavykh, V.P. Ginkin and S.M. Ganina: J. Alloy. Compd., 2014, vol. 586, pp. 267-273.

G. Nie, H.S. Ding, R.R. Chen, J.J. Guo and H.Z. Fu, Mater. Design., 2012, vol. 39, pp. 350-357.

X.F. Ding, J.P. Lin, L.Q. Zhang, Y.Q. Su, H.L. Wang and G.L. Chen: Scri. Mater., 2011, vol. 65, pp. 61-64.

S.L. Dong, R.R. Chen, J.J. Guo, H.S. Ding, Y.Q. Su and H.Z. Fu: Mater. Design., 2015, vol. 67, pp. 390-397.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51274076) and the National Science Fund for Distinguished Young Scholars (NSFC51425402).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 11, 2017.

Rights and permissions

About this article

Cite this article

Chen, R., Yang, Y., Gong, X. et al. Numerical Research on Magnetic Field, Temperature Field and Flow Field During Melting and Directionally Solidifying TiAl Alloys by Electromagnetic Cold Crucible. Metall Mater Trans B 48, 3345–3358 (2017). https://doi.org/10.1007/s11663-017-1068-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1068-8