Abstract—

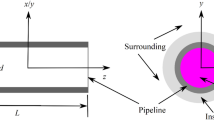

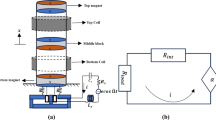

Technologies for pressure shaping of metal workpieces using powerful current pulses are becoming increasingly widespread both in Russia and abroad. Unique electromechanical processes are studied and improved in laboratory and production environments. The application of current to the workpiece is accompanied by a change in its physical properties as a result of the so-called electroplastic effect (EPE). At the same time, the temperature of the workpiece in the deformation zone increases. An automatic force and temperature regulation system is necessary for maintaining high-quality and reliable operation of the drawing mill at electrostimulated drawing (ESW). In order to implement the temperature control circuit, it is necessary to synthesize the transfer function of the control object—steel wire wrought under pressure by rolling or drawing. The synthesis and analysis of the parameters of the temperature control object model are considered. Several known relations are used, such as the dependence of the pulse generator power on the calculated parameters (initial temperature, diameter, specific weight and electrical resistance of the workpiece, pulse duration), dependence of the generator’s RMS current on the amplitude and frequency of pulse reproduction, dependence of the magnetic permeability of the workpiece on its temperature, and dependence of the specific electrical resistance of the conductor material on temperature. The Matlab–Simulink software suite is used to synthesize a model of the temperature control object as a function for parameters of a generator of powerful current pulses (amplitude and frequency), as well as the parameters of the workpiece in processing (diameter, sample length, linear velocity, initial temperature, and resistivity at the initial temperature). The model is analyzed, and transients in different operating modes are presented. The developed model is used for deriving the dependences of the temperature, power, and equivalent resistance on the parameters of the generator and the workpiece at various generator pulse frequencies and workpiece diameters. The developed model can be used for laboratory studies of the electroplastic effect, as well as in producing electrostimulation drawing autocontrol systems in order to implement the controlled object as a model.

Similar content being viewed by others

REFERENCES

Hong, S.-T., Jeong, Y.-H., Chowdhury, M.N., Chun, D.-M., Kim, M.-J., and Han, H.N., Feasibility of electrically assisted progressive forging of aluminum 6061-T6 alloy, CIRP Ann., 2015, vol. 64, no. 1, pp. 277–280. https://doi.org/10.1016/j.cirp.2015.04.084

Perkins, T.A., Kronenberger, T.J., and Roth, J.T., Metallic forging using electrical flow as an alternative to warm/hot working, J. Manuf. Sci. Eng., 2007, vol. 129, no. 1, pp. 84–94. https://doi.org/10.1115/1.2386164

Egea, A.J.S., Rojas, H.A.G., Celentano, D.J., and Peiro, J.J., Mechanical and metallurgical changes on 308L wires drawn by electropulses, Mater. Des., 2016, vol. 90, pp. 1159–1169. https://doi.org/10.1016/j.matdes.2015.11.067

Tang, G., Zhang, J., Zheng, M., Zhang, J., Fang, W., and Li, Q., Experimental study of electroplastic effect on stainless steel wire 304L, Mater. Sci. Eng., A, 2000, vol. 281, nos. 1–2, pp. 263–267. https://doi.org/10.1016/S0921-5093(99)00708-X

Hameed, S., Rojas, H.A.G., Egea, A.J.S., and Alberro, A.N., Electroplastic cutting influence on power consumption during drilling process, Int. J. Adv. Manuf. Technol., 2016, vol. 87, nos. 5–8, pp. 1835–1841. https://doi.org/10.1007/s00170-016-8562-z

Zhang, D., To, S., Zhu, Y.H., Wang, H., and Tang, G.Y., Static electropulsing-induced microstructural changes and their effect on the ultra-precision machining of cold-rolled AZ91 alloy, Metall. Mater. Trans. A, 2012, vol. 43, no. 4, pp. 1341–1346. https://doi.org/10.1007/s11661-011-0955-x

Langer, J., Hoffmann, M.J., and Guillon, O., Direct comparison between hot pressing and electric field-assisted sintering of submicron alumina, Acta Mater., 2009, vol. 57, no. 18, pp. 5454–5465. https://doi.org/10.1016/j.actamat.2009.07.043

Munir, Z.A., Quach, D.V., and Ohyanagi, M., Electric current activation of sintering: a review of the pulsed electric current sintering process, J. Am. Ceram. Soc., 2011, vol. 94, no. 1, pp. 1–19. https://doi.org/10.1111/j.1551-2916.2010.04210.x

Santos, T.G., Miranda, R., and Vilaca, P., Friction stir welding assisted by electrical joule effect, J. Mater. Process. Technol., 2014, vol. 214, no. 10, pp. 2127–2133. https://doi.org/10.1016/j.jmatprotec.2014.03.012

Santos, T.G., Lopes, N., Machado, M., Vilaça, P., and Miranda, R.M., Surface reinforcement of AA5083–H111 by friction stir processing assisted by electrical current, J. Mater. Process. Technol., 2015, vol. 216, pp. 375–380. https://doi.org/10.1016/j.jmatprotec.2014.10.005

Jeswiet, J., Micari, F., Hirt, G., Bramley, A.N., Duflou, J., and Allwood, J., Asymmetric single point incremental forming of sheet metal, CIRP Ann., 2005, vol. 54, no. 2, pp. 88–114. https://doi.org/10.1016/S0007-8506(07)60021-3

Fan, G., Sun, F., Meng, X., Gao, L., and Tong, G., Electric hot incremental forming of Ti–6Al–4V titanium sheet, Int. J. Adv. Manuf. Technol., 2010, vol. 49, pp. 941–947. https://doi.org/10.1007/s00170-009-2472-2

Gromov, V.E., Zuev, A.V., Kozlov, E.V., and Tsellermaer, V.Ya., Elektrostimulitovannaya plastichnost’ metallov i splavov (Electrostimulated Plasticity of Metals and Alloys), Moscow: Nedra, 1996.

Kuznetsov, V.A., Gromov, V.E., and Simakov, V.P., USSR Inventor’s Certificate no. 884092, Byull. Izobret., 1981, no. 43.

Kuznetsov, V.A., Polkovnikov, G.D., Gromov, V.E., Kuznetsova, V.A., and Peregudov, O.A., High power current pulse generator based on reversible thyristor converter, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2019, vol. 62, no. 12, pp. 964–971. https://doi.org/10.17073/0368-0797-2019-12-964-971

Aliferov, A.I. and Lupi, S., Induktsionnyi i elektrokontaktnyi nagrev metallov (Induction and Electric Contact Heating of Metals), Novosibirsk: Novosib. Gos. Tekh. Univ., 2011.

Kashin, Yu.A. and Kulachenkov, G.P., USSR Inventor’s Certificate no. 232995, Byull. Izobret., 1969, no. 2.

Kuznetsov, V.A., Polkovnikov, G.D., Kuznetsova, E.S., and Gromov, V.E., Development of an automatic control system for electrostimulated drawing using powerful current pulses, Trudy Vos’moi Vserossiiskoi nauchno-prakticheskoi konferentsii, Novokuznetsk, 20–21 noyabrya 2018 g. (Proc. Eight All-Russian Sci.-Pract. Conf., Novokuznetsk, November 20–21, 2018), Novokuznetsk: Sib. Gos. Ind. Univ., 2018, pp. 132–138.

Kovrev, G.S., Elektrokontaktnyi nagrev pri obrabotke tsvetnykh metallov (Electric Contact Heating in Non-Ferrous Metals Processing), Moscow: Metallurgiya, 1975.

Romanov, D.I., Elektrokontaktnyi nagrev metallov (Electric Contact Heating of Metals), Moscow: Mashinostroenie, 1981.

Slukhotskii, A.E., Nemkov, V.S., Pavlov, N.A., and Bamuner, A.V., Ustanovki induktsionnogo nagreva (Induction Heating Units), Slukhotskii, A.E., Ed., Leningrad: Energoizdat, 1981.

Smirnov, M.A., Schastlivtsev, V.M., and Zhuravlev, L.G., Osnovy termicheskoi obrabotki stali (Fundamentals of Steel Heat Treatment), Moscow: Nauka i Tekhnologii, 2002.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by S. Kuznetsov

About this article

Cite this article

Kuznetsov, V.A., Kuznetsova, E.S. & Gromov, V.E. Model of Temperature Control by Electrically Stimulating Action Parameters. Steel Transl. 51, 374–378 (2021). https://doi.org/10.3103/S0967091221060061

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221060061