Abstract

Mathematical modeling of differentiated thermal processing of railway rails with air has been carried out. At the first stage, the one-dimensional heat conduction problem with boundary conditions of the third kind was solved analytically and numerically. The obtained temperature distributions at the rail head surface and at a depth of 20 mm from the rolling surface were compared with experimental data. As a result, the coefficient values of heat transfer and thermal conductivity of rail steel were determined. At the second stage, the mathematical model of temperature distribution in a rail template was created in conditions of forced cooling and subsequent cooling under natural convection. The proposed mathematical model is based on the Navier–Stokes and convective thermal conductivity equations for the quenching medium and thermal conductivity equation for rail steel. On the rail–air boundary, the condition of heat flow continuity was set. In conditions of spontaneous cooling, change in the temperature field was simulated by a heat conduction equation with conditions of the third kind. Analytical solution of a one-dimensional heat conduction equation has shown that calculated temperature values differ from the experimental data by 10%. When cooling duration is more than 30 s, the change of pace of temperature versus time curves occurs, which is associated with change in cooling mechanisms. Results of numerical analysis confirm this assumption. Analysis of the two-dimensional model of rail cooling by the finite element method has shown that surface temperature of the rail head decreases sharply both along the central axis and along the fillet at the initial cooling stage. When cooling duration is over 100 s, temperature stabilizes to 307 K. In the central zones of the rail head, the cooling process is slower than in the surface ones. After forced cooling is stopped, heating of the surface layers is observed, due to change in heat flow direction from the central zones to the surface of the rail head, and then cooling occurs at speeds significantly lower than at the first stage. The obtained results can be used to correct differential hardening modes.

Similar content being viewed by others

REFERENCES

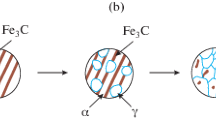

Kuziak, R., Pidvysots’kyy, V., Pernach, M., Rauch, Ł., Zygmunt, T., and Pietrzyk, M., Selection of the best phase transformation model for optimization of manufacturing processes of pearlitic steel rails, Arch. Civ. Mech. Eng., 2019, vol. 19, no. 2, pp. 535–546.

Yahyaoui, H., Sidhom, H., Braham, C., and Baczmanski, A., Effect of interlamellar spacing on the elastoplastic behavior of C70 pearlitic steel: experimental results and self-consistent modeling, Mater. Des., 2014, vol. 55, pp. 888–897.

Kapp, M.W., Hohenwarter, A., Wurster, S., Yang, B., and Pippan, R., Anisotropic deformation characteristics of an ultrafine- and nanolamellar pearlitic steel, Acta Mater., 2016, vol. 106, pp. 239–248.

Borts, A.I., Shur, E.A., Reikhart, V.A., and Bazanov, Yu.A., Results of tests of rails subjected to direct differential quenching. Influence of production technology on their properties, Prom. Transp. XXI Vek, 2009, no. 4, pp. 32–36.

Pavlov, V.V., Korneva, L.V., and Kozyrev, N.A., Selecting a thermal-hardening technology for rails, Steel Transl., 2007, vol. 37, no. 3, pp. 313–315.

Korneva, L.V., Yunin, G.N., Kozyrev, N.A., Atkonova, O.P., and Polevoi, E.V., Quality comparison of OAO NKMK and imported rails, Steel Transl., 2010, vol. 40, no. 12, pp. 1047–1050.

Gromov, V.E., Volkov, K.V., Ivanov, Yu.F., Morozov, K.V., Alsarayeva, K.V., and Konovalov, S.V., Formation of structure, phase composition and faulty substructure in the bulk- and differentially-hard-tempered rails, Prog. Phys. Met., 2014, vol. 15, no. 1, pp. 1–33.

Gromov, V.E., Morozov, K.V., Ivanov, Yu.F., and Glezer, A.M., Analysis of structure-phase states in-a-bulk hardened and a head-hardened rails, AIP Conf. Proc., 2014, vol. 1623, pp. 191–194.

Volkov, K.V., Polevoi, E.V., Temlyantsev, M.V., Atkonova, O.P., Yunusov, A.M., and Syusyukin, A.Yu., Simulation of air jet hardening from furnace heating of railway rails, Vestn. Sib. Gos. Ind. Univ., 2014, no. 3 (9), pp. 17–23.

Sahay, S.S., Mohapatra, G., and Totten, G.E., Overview of pearlitic rail steel: Accelerated cooling, quenching, microstructure, and mechanical properties, J. ASTM Int., 2009, vol. 6, no. 7, pp. 1–26.

Pointner, P., High strength rail steels—the importance of material properties in contact mechanics problems, Wear, 2008, vol. 265, no. 9, pp. 1373–1379.

Behrens, B.-A., Denkena, B., Charlin, F., and Dannenberg, M., Model based optimization of forging process chains by the use of a genetic algorithm, Proc. 10th Int. Conf. on Technology of Plasticity (ICTP), Aachen, 2011, pp. 25–30.

Li, G., Liu, Z., Chen, L., and Hou, X., Numerical calculation of the comprehensive heat transfer coefficient on the surface of rail in the spray cooling process, J. Metall. Eng., 2015, vol. 4, pp. 13–17.

Carslaw, H.S. and Jaeger, J.C., Conduction of Heat in Solids, Oxford: Oxford Univ. Press, 1947.

Zubchenko, A.S., Koloskov, M.M., Kashirskii, Yu.V., et al., Marochnik stalei i splavov (Grade of Steels and Alloys), Zubchenko, A.S., Ed., Moscow: Mashinostroenie, 2003.

Tikhonov, A.N., Kal’ner, V.D., and Glasko, V.B., Matematicheskoe modelirovanie tekhnologicheskikh protsessov i metod resheniya obratnykh zadach v mashinostroenii (Mathematical Modeling of Technological Processes and Method for Solving Inverse Problems in Mechanical Engineering), Moscow: Mashinostroenie, 1990.

Duda, P., A general method for solving transient multidimensional inverse heat transfer problems, Int. J. Heat Mass Transfer, 2016, vol. 93, pp. 665–673.

Samarskii, A.A. and Vabishchevich, P.N., Vychislitel’naya teploperedacha (Computational Heat Transfer), Moscow: URSS Editorial, 2003.

Sarychev, V.D., Nevskii, S.A., Granovskii, A.Yu., and Gromov, V.E., Matematicheskie modeli i mekhanizmy formirovaniya gradientnykh struktur v materialakh pri vneshnikh energeticheskikh vozdeistviyakh: monografiya (Mathematical Models and Mechanisms of Formation of Gradient Structures in Materials under External Energy Influences: Monograph), Novokuznetsk: Sib. Gos. Ind. Univ., 2017.

Sarychev, V.D., Khaimzon, B.B., Nevskii, S.A., Il’yashchenko, A.V., and Grishunin, V.A., Mathematical models of mechanisms for rolled products accelerated cooling, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2018, vol. 61, no. 4, pp. 326–332.

Funding

This study was supported by the Russian Foundation for Basic Research, grant no. 19-32-60001.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by K. Gumerov

About this article

Cite this article

Sarychev, V.D., Molotkov, S.G., Kormyshev, V.E. et al. Simulation of Differentiated Thermal Processing of Railway Rails by Compressed Air. Steel Transl. 50, 848–854 (2020). https://doi.org/10.3103/S096709122012013X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122012013X