Abstract

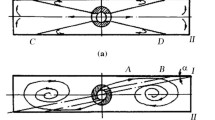

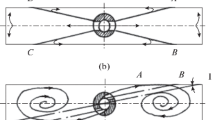

New methods of producing continuous-cast slab cannot be based on equilibrium crystallization of the steel at low speed. If melt is supplied to the wall layers in the mold through a pressurized submerged nozzle with eccentric outputs, the solidification rate of the steel in casting may be significantly increased. The results show that the new technology ensures improved quality in casting slabs of large cross section. When using the experimental nozzle, the width of the columnar-crystal zone is reduced and the disoriented-crystal zone is enlarged, while less axial segregation is observed. In casting by the new technology, heat transfer in the mold is increased by 10–12%. Impact tests reveal characteristics of the metal that are not evident in other tests. Structure formation of the metal in the continuous finishing group of a continuous broad-strip mill and subsequent strip cooling are studied by physical modeling. Tapered low-carbon steel samples taken from slab cooled on the intermediate roller conveyer of the broad-strip mill are rolled in one and two passes on a tworoller high-speed laboratory mill with a bypass unit. The rolling processes are geometrically and kinematically similar. After a fixed holding time in air, the rolled samples are set on one edge by means of a special device for partial quenching in coolant solution. Gradations of reduction are produced over the length of the sample, and gradations of cooling rate are produced over the width. The results of physical modeling illustrate the structure formation in low-carbon steel on rolling and accelerated strip cooling on a continuous broad-strip mill. Using these results and the Hall–Petch equation, specified structure and yield point of the final hotrolled sheet may be ensured. By eliminating the additional slab heating before rolling and improving the product quality, considerable economic benefit may be ensured.

Similar content being viewed by others

References

Protasov, A.V., Pasechnik, N.V., and Sivak, B.A., Elektrometallurgicheskie mini-zavody (Electrometallurgical Mini Plants), Moscow: Metallurgizdat, 2013.

Salganik, V.M., Gun, I.G., Karandaev, A.S., and Radionov, A.A., Tonkoslyabovye liteino-prokatnye agregaty dlya proizvodstva stal’nykh polos: uchebnoe posobie (Thin Slab Foundry and Rolling Aggregates for Steel Strips Production: Manual), Moscow: Mosk. Gos. Ttekh. Univ. im. N.E. Baumana, 2003.

Lamukhin, A.M. and Dubinin, I.V., Startup of a casting-rolling complex and mastery of the production of high quality rolled products for electric-welded pipe, Metallurgist, 2010, vol. 54, nos. 1–2, pp. 19–27.

Vedani, M., Ripamonti, D., Mannucci, A., and Dellasega, D., Hot ductility of microalloyed steels, Metall. Ital., 2008, vol. 5, pp. 19–24.

Sun, H., Su, Y., Wu, C., et al., The improvement of transverse crack on slab for plate products, Proc. AISTech 2014 Conf., Warrendale, PA: Assoc. Iron Steel Technol., 2014, pp. 2923–2930.

Tian, L. and Chen, S., The surface quality of casting defect detection system, Proc. AISTech 2014 Conf., Warrendale, PA: Assoc. Iron Steel Technol., 2014, pp. 1747–1757.

Kim, S.Y., Choi, Y.S., Hwang, J.Y., and Lee, S.H., Mold heat transfer behavior at high casting speed over 7 m/minute in the CEM, POSCO, Iron Steel Technol., 2016, vol. 13, no. 7, pp. 47–56.

Raudensky, M., Tseng, A.A., Horsky, J., and Kominek, J., Recent developments of water and mist spray cooling in continuous casting of steels, Metall. Res. Technol., 2016, vol. 113, no. 5, p. 509.

Hanao, M., Kawamoto, M., and Yamanaka, A. Influence of mold flux on initial solidification of hypo-peritectic steel in a continuous casting mold, J. Iron Steel Inst. Jpn., 2014, vol. 100, no. 4, pp. 581–590.

Kania, H., Nowacki, K., and Lis, T., Impact of the density of the mould powder on thickness of the layer of liquid slag in the continuous caster mould, Metalurgija, 2013, vol. 52, no. 2, pp. 204–206.

Kurisu, J., Mizobe, A., Furukawa, H., and Kuroda, T., The flow optimization design of the SEN for mediumthin slab CC, Refractories, 2014, vol. 66, no. 8, pp. 385–391.

Furumai, K. and Miki, Y., Molten steel flow control technology for decreasing slab defects, JFE Tech. Rep., 2016, vol. 38, pp. 36–41.

Kratzsch, Ch., Timmel, K., Eckert, S., and Schwarze, R., URANS simulation of continuous casting mold flow: assessment of revised turbulence models, Steel Research Int., 2015, vol. 87, no. 4, pp. 400–410.

Sengupta, J. and Yavuz, M.M., Nozzle design for ArcelorMittal Dofasco’s no. 1 continuous caster for minimizing sliver defects, Iron Steel Technol., 2011, vol. 7, pp. 39–47.

Lee, P.B., Ramirez-Lopez, P.E., Mills, K.C., et al., Review: the “butterfly effect” in continuous casting, Ironmaking Steelmaking, 2012, vol. 39, no. 4, pp. 244–253.

Stulov, V.V., Odinokov, V.I., Novikova, T.V., and Chistyakov, I.V., Slab solidification, Steel Transl., 2010, vol. 40, no. 8, pp. 703–705.

Stulov, V.V., Matysik, V.A., Novikova, T.V., et al., Razrabotka novogo sposoba razlivki slyabovykh zagotovok na MNLZ (Development of a New Method of Casting of Slab Blanks in Continuous Casting Machine), Komsomolsk-on-Amur: Inst. Mashinoved. Metall., Dal’nevost. Otd., Ross. Akad. Nauk, 2008.

Stulov, V.V., Improvement of continuous steel casting Based on the study of hydrodynamics and heat transfer in the crystallizer, Extended Abstract of Cand. Sci. (Tech.) Dissertation, Moscow: Moscow Inst. Steel Alloys, 1992.

Stulov, V.V., Odinokov, V.I., Novikova, T.V., and Staroverov, A.D., Effect of the deformation of slabs and the technology used to cast them on the mechanical properties of the resulting rolled products, Metallurgist, 2010, vol. 54, nos. 1–2, pp. 40–44.

Gorelik, S.S., Dobatkin, S.V., and Kaputkina, L.M., Rekristallizatsiya metallov i splavov (Recrystallization of Metals and Alloys), Moscow: Mosk. Inst. Stali Splavov, 2005, 3rd ed.

Dubrovskii, B.A., Nikiforov, B.A., and Radionova, L.V., Investigation of the influence of hot rolling process parameters on the structure of low-carbon and lowalloyed steel, Proizvod. Prokata, 2006, no. 10, pp. 13–16.

Olasolo, M., Uranga, P., Rodriguez-Ibabe, J.M., and Lopez, B., Effect of austenite deformation microstructure and cooling rate on transformation characteristics in a low carbon Nb–V microalloyed steel, Mater. Sci. Eng., A, 2011, vol. 528, pp. 2559–2569.

Yankovskii, A.V., Levchenko, G.V., Vorobei, S.A., Karnaukh, A.I., and Klimenko, A.P., Influence of temperature-deformation parameters of rolling of thinsheet low-carbon steel on kinetics of austenite decomposition, in Fundamental’nye i prikladnye problemy chernoi metallurgii (Fundamental and Applied Problems Iron and Steel Industry), Dnepr: Inst. Chern. Metall., Nats. Akad. Nauk Ukr., 2004, no. 8, pp. 269–274.

Li, Y., Growther, D.N., Mitchell, P.S., and Baker, T.N., The evolution of microstructure during thin slab direct rolling processing in vanadium microalloyed steels, ISIJ Int., 2002, vol. 42, pp. 636–644.

Hulka, K., Gray, J.M., and Heisterkamp, F., High temperature thermomechanical processing of pipeline steels, Proc. Int. Symp. “Niobium,” Orlando, Florida, December 2–5, 2001, Orlando, 2001.

Yun, B.X., Yong, M.Y., Bao, L.X., Zhen, Y.L., and Guo, D.W., Modeling of microstructure evolution during hot rolling of high-Nb HSLA steel, J. Mater. Sci., 2010, vol. 45, no. 10, pp. 2580–2590.

Rudskoi, A.I., Kolbasnikov, N.G., Zotov, O.G., et al., Investigation of the structure and properties of TRIPsteels on the Gleeble-3800 complex, Chern. Met., 2010, no. 2, pp. 8–14.

Futch, D.B., Speer, J.G., Findley, K.O., and Thomas, G.A., Thermomechanical simulation of hot rolled Q&P sheet steels, Iron Steel Technol., 2012, no. 12, pp. 101–106.

Modeling of thermomechanical rolling—a way to reduce cost of new production, Metallurg, 2010, no. 1, p. 3.

Aldunin, A.V., Rusakov, A.D., and Traino, A.I., Issledovanie i razrabotka tekhnologii proizvodstva stal’nykh polos (Research and Development of Steel Strip Production Technologies), Saarbrucken: LAP LAMBERT Academic, 2014.

Aldunin, A.V., Development of hot rolling modes for low-carbon steel using the patterns of structure formation, Proizvod. Prokata, 2007, no. 11, pp. 7–8.

Aldunin, A.V., Optimizing hot strip rolling in terms of the metal structure and plasticity, Steel Transl., 2008, vol. 38, no. 5, pp. 362–365.

Hall, E.O., The deformation and ageing of mild steel: III. Discussion of results, Proc. Phys. Soc. London, B, 1951, vol. 64, no. 9, pp. 747–753.

Petch, N.J., The cleavage strength of polycrystals, J. Iron Steel Inst., 1953, vol. 174, no. 1, pp. 25–28.

Ametistov, E.V., Grigor’ev, V.A., Emtsev, B.T., et al., Teplo-i massoobmen. Teplotekhnicheskii eksperiment: spravochnik (Heat and Mass Transfer: Thermotechnical Experiment. Handbook), Moscow: Energoatomizdat, 1982.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Stulov, A.V. Aldunin, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 10, pp. 798–803.

About this article

Cite this article

Stulov, V.V., Aldunin, A.V. Production of hot-rolled sheet of specified quality by a new slab-casting technology. Steel Transl. 47, 645–649 (2017). https://doi.org/10.3103/S0967091217100096

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217100096