Abstract

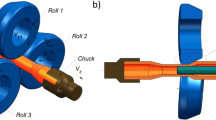

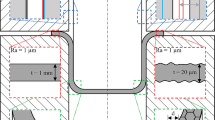

The rolling of balls (diameter 93 and 125 mm) of precise mass in helical grooves is simulated by means of QForm-3D and DEFORM-3D software. A model of a virtual rolling mill is created. Analysis of the stress state at characteristic points along the rolling axis focuses on the effective stress, the components of the stress tensor, and the mean normal stress. The mass of balls rolled on new and worn rollers is measured. The quality of internal metal layers is verified, and the hardness of rolled balls over the vertical and horizontal symmetry axes is measured. Modeling of ball rolling shows that the hot blank (a rod of hot-rolled steel) is satisfactorily captured by the rollers. Rolling is stable, without slipping. The blank completely fills the grooves; no gaps are observed between the metal and the walls. The crosslinks between the balls are completely eliminated within the rollers. The crosslinks are cut by the rim of the rollers and pressed into the body of the ball. The individual balls continue to roll along the finishing section of the groove; the stubs of the crosslinks are smoothed; and a completely shaped ball with a smooth surface emerges from the rollers. In modeling the stress–strain state, all the components of the stress tensor are negative. In other words, all the components of the stress tensor are compressive in rolling of the balls. Statistical analysis of the data from weighing of the rolled balls (diameter 93 and 125 mm) shows that the mass deviates from the required value by no more than 1%. Measurement of the hardness over the diametric cross section of the balls shows that there is no decline in hardness in the internal layers. That indicates high quality of the ball core.

Similar content being viewed by others

References

Tselikov, A.I., Barbarich, M.V., Vasil’chikov, M.V., et al., Spetsial’nye prokatnye stany (Special Rolling Mills), Moscow: Metallurgiya, 1971.

Granovskii, S.P., Novye protsessy i stany dlya prokatki izdelii v vintovykh kalibrakh (New Technologies and Mills for Rolling of Products in Screw Calibers), Moscow: Metallurgiya, 1980.

Kotenok, V.I. and Podobedov, S.I., Energy-efficient design of rolls for ball-rolling mills, Metallurgist, 2001, vol. 45, nos. 9–10, pp. 363–367.

Peretyat’ko, V.N., Klimov, A.S., and Filippova, M.V., Roller grooving in ball-rolling mills. Part 1, Steel Transl., 2013, vol. 43, no. 4, pp. 168–170.

Peretyat’ko, V.N., Klimov, A.S., and Filippova, M.V., Calibration of rolls of a ball-rolling mill. Report 2, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2013, no. 6, pp. 16–20.

Romanenko, V.P. and Sizov, D.V., Simulation of the skew rolling of large ingots in a two-roller mill, Steel Transl., 2011, vol. 40, no. 11, pp. 945–948.

Chumachenko, E.N., Aksenov, S.A., and Logashina, I.V., Mathematical modeling and energy conservation for rolling in passes, Metallurgist, 2010, no. 8, pp. 498–503.

Filippova, M.V., Smetanin, S.V., and Peretyat’ko, V.N., Computer simulation of large-diameter balls rolling, Chern. Metall., 2016, no. 9, pp. 75–78.

Gubanova, N.V., Karelin, F.R., Choporov, V.F., and Yusupov, V.S., Study of rolling in helical rolls by mathematical simulation with the Deform 3D software package, Russ. Metall. (Engl. Transl.), 2011, no. 3, pp. 188–193.

Liu, F., Shan, D., and Lü, Y., Experimental study and numerical simulation of isothermal closed die forging for aluminum alloy rotor, Trans. Nonferrous Met. Soc. China, 2005, vol. 15, no. 2, pp. 136–141.

Kapustova, M., Kravarik, L., and Bliznak, J., Computer simulation of precision die forging, Mach. Des., 2011, vol. 3, no. 2, pp. 143–146.

Gohil, D. and Maisuria, M., Computer simulation technique for the closed die forging process: a modular approach, Proc. 7th WSEAS Int. Conf. on System Science and Simulation in Engineering, Corfu: World Sci. Eng. Acad. Soc., 2008, pp. 61–66.

Ulik, A., Kravarik, L., and Bernadic, L., Research of metal flow in closed die in precision forging, Res. Pap.- Fac. Mater. Sci. Technol., Slovak Univ. Technol., 2009, no. 27, pp. 113–118.

Slagter, W., Florie, C., and Venis, A., Advances in three-dimensional forging process modeling, Proc. 15th Natl. Conf. on Manufacturing Research, Bath: Univ. of Bath, 1999, pp. 73–78.

Skripalenko, M.M., Computer modeling and experimental studies of pinning of ingots in a twin-roll mill of screw rolling, Kuznechno-Shtampovochnoe Proizvod., 2016, no. 12, pp. 22–26.

Ershov, A.A., Loginov, Y.N., and Demakov, S.L., Assessing the consequences of the softening of metal during hot-working by using the software package QForm V8, Metallurgist, 2015, vol. 59, no. 7, pp. 659–663.

Maksimov, V.M. and Khlybov, O.S., Simulation of the firmware processes in the screw rolling mill using QForm, Kuznechno-Shtampovochnoe Proizvod., 2016, no. 12, pp. 17–21.

Kolmogorov, V.L., Napryazheniya, deformatsiya, razrushenie (Stresses, Deformation, and Destruction), Moscow: Metallurgiya, 1970.

Peretyat’ko, V.N., Klimov, A.S., and Filippova, M.V., Calibration of rolls for ball rolling, Vestn. Gorno-Metall. Sekts., Ross. Akad. Estestv. Nauk, Otd. Metall., 2012, vol. 30, pp. 44–50.

Peretyat’ko, V.N., Ball blank, Zagotovitel’noe Proizvod. Mashinostr., 2012, no. 3, pp. 17–19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.V. Filippova, M.V. Temlyantsev, V.N. Peretyat’ko, E.E. Prudkii, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 7, pp. 516–521.

About this article

Cite this article

Filippova, M.V., Temlyantsev, M.V., Peretyat’ko, V.N. et al. Rolling of metal balls. Steel Transl. 47, 435–439 (2017). https://doi.org/10.3103/S0967091217070038

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217070038