Abstract

Deep-drawing is a method in which flat sheets of metal are formed into complex 3-dimensional geometries. Three main types of challenges arise when transitioning from the macro-scale to micro-deep drawing. These can be summarised as: (1) tribological effects, which mainly stem from the relative difference in surface characteristics between the two size scales, (2) material behaviour effects which arise from the increasing heterogeneity of materials that have a decreasing number of grains that are deformed in forming, and (3) dimensional effects which relate to difficulties in handling and inspection of small components at high rates and challenges in manufacturing and monitoring of tool components for use in micro-deep drawing. Various methods or effects can be applied to micro-deep drawing processes to tackle these challenges. This paper reviews research on methods and effects that can be used to improve the robustness in micro-deep drawing processes. Small changes, such as the choice of lubricant and slight changes to the punch geometry are considered, but so are larger changes such as the use of ultrasonic vibration to improve formability and adjustable tooling. The influence of process monitoring and simulation on process robustness is also considered. A summary of methods and effects is drawn at the end to highlight potential space for innovation.

Similar content being viewed by others

References

Pelz PF, Groche P, Pfetsch ME, Schaeffner M (2021) Mastering Uncertainty in Mechanical Engineering, 1st ed. Springer, [Online]. Available: https://link.springer.com/book/10.1007/978-3-030-78354-9

Bonte MHA, Van Den Boogaard AH, Van Ravenswaaij R (2007) A robust optimisation strategy for metal forming processes, in AIP Conference Proceedings, pp. 493–498. https://doi.org/10.1063/1.2740859

Pawelski O (1992) Ways and limits of the theory of similarity in application to problems of physics and metal forming. J Mater Process Technol 34:19–30. https://doi.org/10.1016/0924-0136(92)90086-8

Geiger M, Kleiner M, Eckstein R, Tiesler NA, Engel U (2001) Microforming, CIRP Ann Manuf Technol, vol. 50, no. 2, pp. 445–462, https://doi.org/10.1016/S0007-8506(07)62991-6

Van Brussel H, Peirs J, Reynaerts D, Delchambre A, Reinhart G, Roth N, Weck M, Zussman E (2000) Assembly of Microsystems. Annals CIRP 49(2):451–472. https://doi.org/10.1016/S0007-8506(07)63450-7

Fu MW, Chan WL, Yang B (2011) Study of size effects on material deformation behaviour in micro-deep drawing of copper sheet metal, in Special edition: 10th International Conference on Technology of Plasticity, G. Hirt and A. E. Tekkaya, Eds., Aachen, Germany: Wiley-VCH Verlag GmbH & Co. KGaA. Weinheim, pp. 985–990

Kals RTA (1998) Fundamentals on the miniaturization of sheet metal working processes, Ph.D. thesis, University of Erlangen-Nuremberg, Erlangen, Germany, https://doi.org/10.25593/3-87525-115-6

Xu Z, Peng L, Fu MW, Lai X (2015) Size effect affected formability of sheet metals in micro/meso scale plastic deformation: experiment and modeling. Int J Plast 68:34–54. https://doi.org/10.1016/j.ijplas.2014.11.002

Tiesler NA, Engel U (2000) Microforming - effects of miniaturization. In: Pietrzyk M, Kusiak J, Majta J, Hartley P, Pillinger I (eds) in Metal forming 2000. Taylor & Francis, pp 355–360

Lanza G, Schlipf M, Fleischer J (2008) Quality assurance for micro manufacturing processes and primary-shaped micro components. Microsyst Technol 14(12):1823–1830. https://doi.org/10.1007/s00542-008-0608-1

Vollertsen F, Hu Z (2008) Determination of size-dependent friction functions in sheet metal forming with respect to the distribution of the contact pressure. Prod Eng Res Devel 2(4):345–350. https://doi.org/10.1007/s11740-008-0130-4

Shimizu T, Murashige Y, Ito K, Manabe K (2009) Influence of surface topographical interaction between tool and material in micro-deep drawing. J Solid Mech Mater Eng 3(2):397–408. https://doi.org/10.1299/jmmp.3.397

Stoyanov P, Chromik RR (2017) Scaling effects on materials tribology: from macro to micro scale. Materials 10(5). https://doi.org/10.3390/ma10050550

Shimizu T, Murashige Y, Iwaoka S, Yang M, Manabe K (2013) Scale dependence of adhesion behavior under dry friction in progressive micro-deep drawing. J Solid Mech Mater Eng 7(2):251–263. https://doi.org/10.1299/jmmp.7.251

Gong F, Guo B (2013) Effects of solid lubrication film on SKD11 in micro sheet forming. Surf Coat Technol 232:814–820. https://doi.org/10.1016/j.surfcoat.2013.06.103

Guo B, Gong F, Wang C, Shan D (2010) Size effect on friction in scaled down strip drawing. J Mater Sci 45:4067–4072. https://doi.org/10.1007/s10853-010-4492-6

Shimizu T, Iwaoka S, Yang M, Manabe K (2011) Scale dependence of dry friction in micro sheet metal forming, in 10th International Conference on Technology of Plasticity, Steel Research International, pp. 979–984

Luo L, Jiang Z, Wei D (2017) Influences of micro-friction on surface finish in micro deep drawing of SUS304 cups. Wear 374–375. https://doi.org/10.1016/j.wear.2016.11.043

Flosky H, Vollertsen F (2014) Wear behaviour in a combined micro blanking and deep drawing process. CIRP Ann Manuf Technol 63(1):281–284. https://doi.org/10.1016/j.cirp.2014.03.125

Kim HS, Lee YS (Feb. 2012) Size dependence of flow stress and plastic behaviour in microforming of polycrystalline metallic materials. Proc Inst Mech Eng C J Mech Eng Sci 226(2):403–412. https://doi.org/10.1177/0954406211414473

Hoffmann H, Hong S (2006) Tensile test of very thin sheet metal and determination of flow stress considering the scaling effect. Annals CIRP 55(1). https://doi.org/10.1016/S0007-8506(07)60412-0

Zhu C, Xu J, Yu H, Shan D, Guo B (2021) Size effect on the high strain rate micro/meso-tensile behaviors of pure titanium foil. J Mater Res Technol 11:2146–2159. https://doi.org/10.1016/J.JMRT.2021.02.022

Liu JG, Fu MW, Lu J, Chan WL (2011) Influence of size effect on the springback of sheet metal foils in micro-bending. Comput Mater Sci 50(9):2604–2614. https://doi.org/10.1016/j.commatsci.2011.04.002

Chan WL, Fu MW, Yang B (2012) Experimental studies of the size effect affected microscale plastic deformation in micro upsetting process. Mater Sci Eng A 534:374–383. https://doi.org/10.1016/j.msea.2011.11.083

Fang Z, Jiang Z, Wang X, Zhou C, Wei D, Liu X (2015) Grain size effect of thickness/average grain size on mechanical behaviour, fracture mechanism and constitutive model for phosphor bronze foil. Int J Adv Manuf Technol 79:9–12. https://doi.org/10.1007/s00170-015-6928-2

Han P, Yuan G, Zhu X, Xing Y, Wang X (2022) Grain size effect of pure Ti foils by micro blanking-deep-drawing compound process. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-022-10279-z

Xu Z, Peng L, Bao E (2018) Size effect affected springback in micro/meso scale bending process: experiments and numerical modeling. J Mater Process Technol 252:407–420. https://doi.org/10.1016/j.jmatprotec.2017.08.040

Diehl A, Engel U, Geiger M (2010) Influence of microstructure on the mechanical properties and the forming behaviour of very thin metal foils. Int J Adv Manuf Technol 47:1–4. https://doi.org/10.1007/s00170-008-1851-4

Meng B, Zhang YY, Cheng C, Han JQ, Wan M (2018) Effect of plastic anisotropy on microscale ductile fracture and microformability of stainless steel foil. Int J Mech Sci 148:620–635. https://doi.org/10.1016/j.ijmecsci.2018.09.027

Zhu C, Xu J, Yu H, Shan D, Guo B (2021) Grain size effect on formability in electromagnetically assisted micro-bulging of pure titanium sheet. in Minerals, metals and materials Series. Springer Science and Business Media Deutschland GmbH, pp 1351–1359. doi: https://doi.org/10.1007/978-3-030-75381-8_112.

Gau J-T, Principe C, Wang J (2007) An experimental study on size effects on flow stress and formability of aluminm and brass for microforming. J Mater Process Technol 184:42–46. https://doi.org/10.1016/j.jmatprotec.2006.11.003

Meng B, Fu MW (2015) Size effect on deformation behavior and ductile fracture in microforming of pure copper sheets considering free surface roughening. Mater Des 83:400–412. https://doi.org/10.1016/j.matdes.2015.06.067

Furushima T, Tsunezaki H, Manabe K, Alexsandrov S (2014) Ductile fracture and free surface roughening behaviors of pure copper foils for micro/meso-scale forming. Int J Mach Tools Manuf 76:34–48. https://doi.org/10.1016/j.ijmachtools.2013.10.001

Groche P, Schäfer R, Justinger H, Ludwig M (2010) On the correlation between crystallographic grain size and surface evolution in metal forming processes. Int J Mech Sci 52(3):523–530. https://doi.org/10.1016/j.ijmecsci.2009.11.017

Zhao J, Brockett A, Razali AR, Qin Y, Harrison C, Ma Y (2010) Micro-sheet-forming and case studies. Steel Res Int 81(9):1185–1188. https://doi.org/10.1002/srin.201190002

Behrens G, Vollertsen F (2013) Influence of Tool geometry variation on the Punch Force in Micro Deep drawing. Key Eng Mater 554–557. https://doi.org/10.4028/www.scientific.net/KEM.554-557.1306

Hu Z (2011) Realisation and application of size dependent FEM-simulation for deep drawing of rectangular work pieces. CIRP J Manuf Sci Technol 4(1):90–95. https://doi.org/10.1016/j.cirpj.2011.05.006

Luo L, Wei D, Zu G, Jiang Z (2021) Influence of blank holder-die gap on micro-deep drawing of SUS304 cups. Int J Mech Sci 191. https://doi.org/10.1016/J.IJMECSCI.2020.106065

Fujimoto K, Yang M, Hotta M, Koyama H, Nakano S, Morikawa K, Cairney J (2006) Fabrication of dies in micro-scale for micro-sheet metal forming. J Mater Process Technol 177:1–3. https://doi.org/10.1016/j.jmatprotec.2006.04.094

Nielsen PS, Paldan NA, Calaon M, Bay N (2010) Scale effects in metal-forming friction and lubrication. J Eng Tribology 225:924–931. https://doi.org/10.1177/1350650111405254

Gong F, Guo B, Wang CJ, bin Shan D (2010) Effects of lubrication conditions on micro deep drawing, Microsystem Technologies, vol. 16, no. 10, pp. 1741–1747, Oct. https://doi.org/10.1007/s00542-010-1108-7

Tetzel H (2015) Influence of tribology size effect on Stribeck curve in micro deep drawing. MATEC Web Conferences 21. https://doi.org/10.1051/matecconf/20152109014

Rathmann L, Czotscher T, Radel T, Vollertsen F (2020) Investigation on water as lubricant in combination with a structured tool surface in micro metal forming. IOP Conf Ser Mater Sci Eng 967(1). https://doi.org/10.1088/1757-899X/967/1/012005

Arinbjarnar Ú, Moghadam M, Nielsen CV (2022) Application of calcium carbonate as green lubricant additive in sheet metal forming. Key Eng Mater 926:1133–1142. https://doi.org/10.4028/p-x87o62

Arinbjarnar Ú, Moghadam M, Nielsen CV (2024) Application of calcium carbonate as a green lubricant additive in an industrial context of sheet metal forming

Zhou M, Jia F, Yan J, Wu H, Jiang Z (2022) Lubrication performance and mechanism of water-based TiO2 nanolubricants in micro deep drawing of pure titanium foils. Lubricants 10(11):292. https://doi.org/10.3390/lubricants10110292

Kamali H, Xie H, Jia F, Wu H, Zhao H (2019) Effects of nano-particle lubrication on micro deep drawing of Mg-Li alloy. Int J Adv Manuf Technol 104:9–12. https://doi.org/10.1007/s00170-019-04267-z

Kamali H, Xie H, Zhao H, Jia F, Wu H, Jiang Z (2020) Frictional size effect of light-weight Mg-Li alloy in micro deep drawing under nano-particle lubrication condition. Mater Trans 61(2):239–243. https://doi.org/10.2320/matertrans.MT-ML2019002

Srinivasan N, Rajenthirakumar D, Sridhar R, Amutha P (2020) Tribomechanical performance of MgO–ZnO nanoparticles as lubricating additives in the microextrusion process. Proc Inst Mech Eng C J Mech Eng Sci 234(22):4543–4553. https://doi.org/10.1177/0954406220922859

Brinksmeier E, Gläbe R, Riemer O, Twardy S (2008) Potentials of precision machining processes for the manufacture of micro forming molds. Microsyst Technol 14(12):1983–1987. https://doi.org/10.1007/s00542-008-0656-6

Wang C, Guo B, Shan D, Yao Y, Gong F (2010) Size effect of tribology behaviour in micro U-deep drawing with T2 copper foil. Steel Res Int 81(9):1177–1180

Bech JI, Bay N, Eriksen M (1999) Entrapment and escape of liquid lubricant in metal forming. Wear 232:134–139. https://doi.org/10.1016/S0043-1648(99)00136-2

Shimizu I, Martins PAF, Bay N, Andreasen JL, Bech JI (2010) Influences of lubricant pocket geometry and working conditions upon micro-lubrication mechanisms in upsetting and strip drawing. Int J Surf Sci Eng 4(1):42–54. https://doi.org/10.1504/ijsurfse.2010.029628

Nellemann T, Bay N, Wanheim T (1977) Real area of contact and friction stress - the role of trapped lubricant. Wear 43:45–53. https://doi.org/10.1016/0043-1648(77)90042-4

Zwicker M, Spangenberg J, Martins P, Nielsen CV (2022) Investigation of material strength and oil compressibility on the hydrostatic pressure build-up in metal forming lubricants, in Procedia CIRP, Elsevier B.V., pp. 78–82. https://doi.org/10.1016/j.procir.2022.10.053

Mizuno T, Okamoto M (1982) Effects of lubricant viscosity at pressure and sliding velocity on lubricating conditions in the compression-friction test on sheet metals. Trans ASME: J Lubrication Technol 104(1):53–59. https://doi.org/10.1115/1.3253164

Bech JI, Bay N, Eriksen M (1998) A study of mechanisms of liquid lubrication in metal forming. Annals CIRP 47(1):221–226. https://doi.org/10.1016/S0007-8506(07)62822-4

Sulaiman MH, Christiansen P, Bay N (2017) The influence of tool texture on friction and lubrication in strip reduction testing. Lubricants 5(1). https://doi.org/10.3390/lubricants5010003

Schumann P, Lindner R, Groche P (2023) Influence of different deterministic surface texturing processes on friction and tool life for load collectives in sheet metal forming, in Proceedings of the Tribology 2023 International Conference, Lissabon, Portugal

Steitz M, Stein P, Groche P (2015) Influence of hammer peened surface textures. Tribol Lett 58(24). https://doi.org/10.1007/s11249-015-0502-9

Steitz M, Klasen P, Groche P (2015) Wear behavior of hammer peened surface textures during strip drawing test, in Proceeding of the 34th International Deep Drawing Research Group Conference, pp. 270–281

Uehara Y, Wakuda M, Yamauchi Y, Kanzaki S, Sakaguchi S (2004) Tribological properties of dimpled silicon nitride under oil lubrication. J Eur Ceram Soc 24(2):369–373. https://doi.org/10.1016/S0955-2219(03)00220-6

Jahn SF, Müller B, Hilfinger FS, Schubert A (2015) Tribological impact of the finishing technology onto meso-and microforming processes, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/20152109009

Twardy S, Riemer O, Brinksmeier E (2010) Tribology of micro milled surfaces. Key Eng Mater 447 448:681–684. https://doi.org/10.4028/www.scientific.net/KEM.447-448.681

Wang C, Guo B, Shan D, Bai X (2015) Effects of interfacial contact states on tribological behaviour in micro-sheet forming. Int J Mech Sci 101–102. https://doi.org/10.1016/j.ijmecsci.2015.07.018

Funazuka T, Dohda K, Shiratori T, Horiuchi S, Watanabe I (2001) Effect of punch surface microtexture on the microextrudability of AA6063 micro backward extrusion, Micromachines (Basel), vol. 13, no. 2022, https://doi.org/10.3390/mi13112001

Castagne S, Taureza M, Song X (2014) Surface textures and friction control in microforming. Adv Mat Res 966–967. https://doi.org/10.4028/www.scientific.net/AMR.966-967.111

Wang C, Shan D, Guo B, Xu J, Zhang H (2013) Effect of nano-crystals at surfaces induced by ion beam irradiation on the tribological behaviour in microforming. Vacuum 89(1):267–270. https://doi.org/10.1016/j.vacuum.2012.07.007

Lin HS, Lin YC, Lee MR (2015) Effect of workpiece thickness and surface texturing on the micro cupping tests. in Key Engineering materials. Trans Tech Publications Ltd, pp 420–425. doi: https://doi.org/10.4028/www.scientific.net/KEM.626.420.

Gong F, Guo B (2013) Effects of influencing factors on friction coefficient in microsheet forming. Mater Res Innovations. https://doi.org/10.1179/1432891713Z.000000000176

Ma J, Gong F, Yang Z, Zeng W (2016) Microdeep drawing of C1100 microsquare cups using microforming technology. Int J Adv Manuf Technol 82:5–8. https://doi.org/10.1007/s00170-015-7476-5

Gong F, Yang Z, Chen Q, Xie Z, Shu D, Yang J (2015) Influences of lubrication conditions and blank holder force on micro deep drawing of C1100 micro conical-cylindrical cup. Precis Eng 42:224–230. https://doi.org/10.1016/j.precisioneng.2015.05.004

Losch A (2014) Sheet metal forming lubricants. in Encyclopedia of lubricants and Lubrication. Springer, Berlin Heidelberg, pp 1749–1764. doi: https://doi.org/10.1007/978-3-642-22647-2.

Shimizu T, Yang M, Manabe K (2015) Classification of mesoscopic tribological properties under dry sliding friction for microforming operation. Wear 330–331. https://doi.org/10.1016/J.WEAR.2015.01.050

Flosky H, Veenaas S, Feuerhahn F, Hartmann M, Vollertsen F (2014) Flaking during a micro blanking and deep drawing process, in Proceedings of the ICOMM2014, Bremen, Germany

Wang C, Wang C, Guo B, Shan D (2014) Effects of tribological behavior of DLC film on micro-deep drawing processes. Trans Nonferrous Met Soc China (English Edition) 24(9):2877–2882. https://doi.org/10.1016/S1003-6326(14)63421-X

Jean MD, Lian GF, Chen BS (2018) Tribological behaviors of DLC films and their application in micro-deep drawability. Acta Phys Pol A 134(1):429–433. https://doi.org/10.12693/APhysPolA.134.429

Wang CJ, Cheng LD, Liu Y, Zhang H, Wang Y, Shan D, Guo B (2019) Research on micro-deep drawing process of concial part with ultra-thin copper foil using multi-layered DLC film-coated die. Int J Adv Manuf Technol 100:1–4. https://doi.org/10.1007/s00170-018-2757-4

Hu Z, Wielage H, Vollertsen F (2011) Economic micro forming using DLC-and TiN-coated tools. J Technol Plast 36(2). https://doi.org/10.2478/v10211-011-0006-z

Hu Z, Schubnov A, Vollertsen F (2012) Tribological behaviour of DLC-films and their application in micro deep drawing. J Mater Process Technol 212(3):647–652. https://doi.org/10.1016/j.jmatprotec.2011.10.012

Wang C, Wang C, Guo B, Shan D (2014) Effect of tribological behavior of DLC film on micro-deep drawing processes. Trans Nonferrous Met Soc China 24:2877–2882. https://doi.org/10.1016/S1003-6326(14)63421-X

Flosky H, Vollertsen F (2013) Wear behavior of a DLC-coated blanking and deep drawing tool combination. Key Eng Mater 549:511–517. https://doi.org/10.4028/www.scientific.net/KEM.549.511

Sulaiman MH, Christiansen P, Bay N (2017) A study of DLC coatings for ironing of stainless steel, in Journal of Physics: Conference Series, Institute of Physics Publishing, https://doi.org/10.1088/1742-6596/896/1/012031

Khadem M, Penkov OV, Yang HK, Kim DE (2017) Tribology of multilayer coatings for wear reduction: A review, Friction, vol. 5, no. 3. Tsinghua University Press, pp. 248–262, https://doi.org/10.1007/s40544-017-0181-7

Dang C, Li J, Wang Y, Yang Y, Wang Y, Chen J (2017) Influence of multi-interfacial structure on mechanical and tribological properties of TiSiN/Ag multilayer coatings. J Mater Sci 52(5):2511–2523. https://doi.org/10.1007/s10853-016-0545-9

Aizawa T (2019) Nanostructured DLC coating for protection of dies from wear-application of nanostructured DLC coating with tailored densities to dies. J JSTP 60(702):209–213

Shimizu T, Kakegawa T, Yang M (2014) Micro-texturing of DLC thin film coatings and its tribological performance under dry sliding friction for microforming operation. in Procedia Engineering. Elsevier Ltd, pp 1884–1889. doi: https://doi.org/10.1016/j.proeng.2014.10.251.

Shimizu T, Kan H, Messaoudi H, Vollertsen F, Yang M (2018) Geometrical design of micro-textured DLC coatings toward lubricant-free metal forming, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/201819013001

Shimizu T, Kan H, Messaoudi H, Vollertsen F, Yang M (2019) Impact of geometrical parameters of micro-textured DLC on tribological properties under dry sliding friction. Manuf Rev (Les Ulis) 6. https://doi.org/10.1051/mfreview/2019018

Omidvarnia F, Weng Feng L, Hansen HN, Sarhadi A, Lenau TA, Mortensen NH (2018) Design for manufacturability of macro and micro products: a case study of heat exchanger design. Int J Interact Des Manuf 12(3):995–1006. https://doi.org/10.1007/s12008-018-0457-9

Toenjes A, Kovac J, Koehler B, Von Hehl A, Mehner A, Clausen B, Zoch HW (2018) Process chain for the fabrication of hardenable aluminium-zirconium micro-components by deep drawing, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/201819015013

Hansen HN, Zhang Y, Islam A (2017) Tolerances in micro manufacturing, in World Congress on Micro and Nano Manufacturing (WCMNM 2017), Kaohsiung, Taiwan

Onken AK, Wilhelmi P, Tracht K, Kuhfuss B (2018) Increased output in micro production by tolerance field widening and synchronisation, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/201819015006

Zhao J, Yip ALK, Qin Y, Razali A, Fei ZC (2012) Machine and tool development for forming of polymeric tubular micro-components, Transactions of Nonferrous Metals Society of China (English Edition), vol. 22, no. SUPPL.2, https://doi.org/10.1016/S1003-6326(12)61711-7

Razali AR, Ann CT, Ahmad AF, Shariff HM, Kasim NI, Musa MA (2017) Finite element structural analysis of a low energy micro sheet forming machine concept design, in IOP Conference Series: Materials Science and Engineering, Institute of Physics Publishing, https://doi.org/10.1088/1757-899X/203/1/012006

Qin Y, Razali AR, Zhou M, Zhao J, Harrison C, Wan Nawang WA (2012) Dynamic characteristics of a micro-sheet-forming machine system. Key Eng Mater 504–506. https://doi.org/10.4028/www.scientific.net/KEM.504-506.599

Behrens BA, Krimm R, Reich D, Teichrib S (2016) Linear drives in metal forming machines and peripherals - recent developments. J Manuf Process 22:192–198. https://doi.org/10.1016/j.jmapro.2016.03.013

Schneider R, Schepp F, Groche P (2001) Linearmotorpressen zur inline-Fertigung von mikrotechnischen Bauteilen, EFB-Kolloquium 2001

Groche P, Schneider R (2004) Method for the optimization of forming presses for the manufacturing of micro parts. CIRP Ann 53(1):281–284. https://doi.org/10.1016/S0007-8506(07)60698-2

Niehoff HS, Vollertsen F (2008) Versatile microforming press. Int J Mater Prod Technol 32(4):423–433. https://doi.org/10.1504/ijmpt.2008.022144

Xu J, Guo B, Shan D, Wang C, Li J, Liu Y, Qu D (2012) Development of a micro-forming system for micro-punching process of micro-hole arrays in brass foil. J Mater Process Technol 212(11):2238–2246. https://doi.org/10.1016/j.jmatprotec.2012.06.020

Qin Y, Ma Y, Harrison C, Brockett A, Zhou M, Zhao J, Law F, Razali AR, Smith R, Eguia J (2008) Development of a new machine system for the forming of micro-sheet-products. IntJ Mater Form no. Suppl 1:475–478. https://doi.org/10.1007/s12289-008-0098-9

Qin Y, Harrison C, Ma Y, Brockett A, Juster N, Uriarte L, Cuevas A, Eguia J (2007) Process and machine system development for the forming of miniature/micro sheet metal products, in Proceedings of the 7th Euspen International Conference, Bremen

Zhou M, Qin Y, Harrison C, Brockett A, Ma Y (2010) Finite-element and experimental analysis of dynamic behaviours of a micro-stamping tool system. Int J Adv Manuf Technol 47:9–12. https://doi.org/10.1007/s00170-009-2138-0

Presz W, Andersen B, Wanheim T (2006) Piezoelectric driven micro-press for microforming manufacturing and processing. J Achievement Mater Manuf Eng 18:1–2

Lee H-J, Lee N-K, Lee G-A-, Lee H-W, Choi S, Chu E-D, Kim T, Shin J (2008) Research on the modulating of the desktop micro forming system to micro factory, in Proceedings of the International Conference on Smart Manufacturing Application, pp. 196–199

OMEGA-F1/EPS-30-Series Yamada Dobby. Accessed: Sep. 06, 2023. [Online]. Available: http://www.yamadadobby.com/en/omega.html

BSTA 200 Bruderer. Accessed: Sep. 06, 2023. [Online]. Available: https://www.bruderer.com/en/products/stamping-presses/bsta-200

High-speed press VS Mabu. Accessed: Sep. 06, 2023. [Online]. Available: https://www.mabu.de/en/High-speed_press_VS

Hadi S, Yu HL, Tieu K, Lu C (2013) Simulation of defects in micro-deep drawing of an aluminium alloy foil. AIP Conf Proc 1532:298–303. https://doi.org/10.1063/1.4806838

Hu D, Zheng JY, Fu MW (2022) Study on size-related product quality of multiscale central-punched cups fabricated by compound forming directly using brass sheet. Int J Adv Manuf Technol 120:11–12. https://doi.org/10.1007/s00170-022-09222-z

Zheng JY, Yang HP, Fu MW, Ng C (2019) Study on size effect affected progressive microforming of conical flanged parts directly using sheet metals. J Mater Process Technol 272:72–86. https://doi.org/10.1016/j.jmatprotec.2019.05.007

Zhang R, Lan S, Xu Z, Qiu D, Peng L (2021) Investigation and optimization of the ultra-thin metallic bipolar plate multi-stage forming for proton exchange membrane fuel cell. J Power Sources 484. https://doi.org/10.1016/j.jpowsour.2020.229298

Li WT, Fu MW, Wang JL, Meng B (2016) Grain size effect on multi-stage micro deep drawing of micro cup with domed bottom. Int J Precis Eng Manuf 17(6):765–773. https://doi.org/10.1007/s12541-016-0094-9

Gau J-T, Chen P-H, Gu H, Lee R-S (2013) The coupling influence of size effects and strain rates on the formability of austenitic stainless steel 304 foil. J Mater Process Technol 213:376–382. https://doi.org/10.1016/j.jmatprotec.2012.10.004

Talyan V, Wagoner RH, Lee JK (1998) Formability of Stainless Steel. Metall Mater Trans A 29A:2161–2172. https://doi.org/10.1007/s11661-998-0041-1

Vollertsen F, Hu Z (2010) Analysis of punch velocity dependant process window in micro deep drawing. Prod Eng Res Devel 4(6):553–559. https://doi.org/10.1007/s11740-010-0241-6

Vollertsen F (2012) Effects on the deep drawing diagram in micro forming. Prod Eng Res Devel 6(1):11–18. https://doi.org/10.1007/s11740-011-0355-5

Wielage H, Hu Z, Vollertsen F (2012) Influence of punch velocity on spring back in micro forming. Key Eng Mater 504–506. https://doi.org/10.4028/www.scientific.net/KEM.504-506.593

Justinger H, Hirt G (2007) Analysis of size-effects in the miniaturized deep drawing process. Key Eng Mater 344:791–798. https://doi.org/10.4028/www.scientific.net/kem.798-344.791

Behrens G, Ruhe M, Tetzel H, Vollertsen F (2015) Effect of tool geometry variations on the punch force in micro deep drawing of rectangular components. Prod Eng Res Devel 9(2):195–201. https://doi.org/10.1007/s11740-015-0604-0

Behrens G, Trier FO, Tetzel H, Vollertsen F (2016) Influence of tool geometry variations on the limiting drawing ratio in micro deep drawing. IntJ Mater Form 9(2):253–258. https://doi.org/10.1007/s12289-015-1228-9

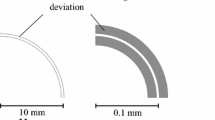

Heinrich L, Kobayashi H, Shimizu T, Yang M, Vollertsen F (2017) Influence of asymmetrical drawing radius deviation in micro deep drawing. J Phys Conf Ser 896(1). https://doi.org/10.1088/1742-6596/896/1/012060

Fu MW, Yang B, Chan WL (2013) Experimental and simulation studies of micro blanking and deep drawing compound process using copper sheet. J Mater Process Technol 213(1):101–110. https://doi.org/10.1016/j.jmatprotec.2012.08.007

Yeh FH, Li CL, Tsay KN (2012) An analysis of forming limit for various arc radii of punch in micro deep drawing of the square cup. Adv Mat Res 433–440. https://doi.org/10.4028/www.scientific.net/AMR.433-440.660

Saotome Y, Yasuda K, Kaga H (2001) Microdeep drawability of very thin sheet steels. J Mater Process Technol 113:641–647. https://doi.org/10.1016/S0924-0136(01)00626-4

Brabie G, Costache E, Bologan M (2013) Influence of the tool clearance values on the quality of the small drawn parts. Appl Mech Mater 371:705–709. https://doi.org/10.4028/www.scientific.net/AMM.371.705

Brabie G, Chirita B, Costache E, Teaca S (2014) Influence of the tool clearances on the dimensional accuracy of mini drawn parts. Adv Mat Res 1036:309–313. https://doi.org/10.4028/www.scientific.net/AMR.1036.309

Stellin T, Van Tijum R, Merklein M, Engel U (2014) Study of microforging of parallel ribs from metal strip, in Key Engineering Materials, Trans Tech Publications Ltd, pp. 565–572. https://doi.org/10.4028/www.scientific.net/KEM.611-612.565

Stock G (1996) Alternative Verfahren zur Verbesserung des Tiefziehergebnisses auf Einfachwirkenden Pressen, Fertigungstechnik, vol. 380. VDI-Verlag, Düsseldorf

Doege E, Elend L-E (2001) Design and application of pliable blank holder systems for the optimization of process conditions in sheet metal forming. J Mater Process Technol 111:182–187. https://doi.org/10.1016/S0924-0136(01)00506-4

Allwood JM, Duncan SR, Cao J, Groche P, Hirt G, Kinsey B, Kuboki T, Liewald M, Sterzing A, Tekkaya AE (2016) Closed-loop control of product properties in metal forming. CIRP Ann Manuf Technol 65(2):573–596. https://doi.org/10.1016/j.cirp.2016.06.002

Spur G, Thoms V, Liewald M, Straube O (1994) Regelung Des Tiefziehprozesses in Der Preßteilefertigung Mit dem blechkanteneinlauf als Regelgröße. Blech Rohre Profile 41(4):237–240

Spur G, Straube O (1994) Materialflußsteuerung unter dem Niederhalter im geschlossenen Regelkreis, in Neuere Entwicklungen in der Blechumformung, pp. 293–306

Bräunlich H (2002) Blecheinzugsregelung beim Tiefziehen mit Niederhalter - ein Beitrag zur Erhöhung der Prozeßstabilität. Verl. Wiss. Scripten., Zwickau

Griesbach B (2000) In-Prozeß Stoffflußmessung zur Analyse und Führung von Tiefziehvorgängen, Fertigungstechnik, vol. 547. VDI-Verlag, Düsseldorf

Rittmeier D-W-IS (2007) Systemunterstützte Umformung. Cuvillier, Göttingen

Tommerup S, Endelt B (2012) Experimental verification of a deep drawing tool system for adaptive blank holder pressure distribution. J Mater Process Technol 212(11):2529–2540. https://doi.org/10.1016/j.jmatprotec.2012.06.015

Kraft M, Bürgel U (2017) Novel concept for measurement of global blank draw-in when deep drawing outer skin automotive components, in Journal of Physics: Conference Series, Institute of Physics Publishing, https://doi.org/10.1088/1742-6596/896/1/012034

Groche P, Breunig A, Chen K, Molitor DA, Ha J, Kinsey BL, Korkolis YP (2022) Effectiveness of different closed-loop control strategies for deep drawing on single-acting 3D servo presses. CIRP Ann 71(1):357–360. https://doi.org/10.1016/j.cirp.2022.04.072

Simonetto E, Ghiotti A, Brun M, Bruschi S, Filippi S (2023) Adaptive metal flow control in stamping through ferrofluidic actuators. CIRP Ann 72:209–212. https://doi.org/10.1016/j.cirp.2023.03.030

Calmano S, Hesse D, Hoppe F, Groche P (2015) Evaluation of control strategies in forming processes, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/20152104002

Heingärtner J, Renkci Y, Hora P (2013) Application of non-destructive testing to control material properties of stainless steel in kitchen sink production. in Towards Zero Fail Prod Methods Adv Model Techniques Process Integr Virtual Control, pp. 75–80

Heingärtner J, Fischer P, Harsch D, Renkci Y, Hora P (2017) Q-Guard - An intelligent process control system, in Journal of Physics: Conference Series, Institute of Physics Publishing, https://doi.org/10.1088/1742-6596/896/1/012032

Fischer P, Harsch D, Heingärtner J, Renkci Y, Hora P (2017) A knowledge-based control system for the robust manufacturing of deep drawn parts. Procedia Eng 207:42–47. https://doi.org/10.1016/j.proeng.2017.10.735

Fischer P, Heingärtner J, Renkci Y, Hora P (2018) Experiences with inline feedback control and data acquisition in deep drawing. Procedia Manuf 15:949–954. https://doi.org/10.1016/j.promfg.2018.07.401

Fischer P, Harsch D, Heingartner J, Renkci Y, Hora P (2018) Implementation of feedback control in kitchen sink production, in IOP Conference Series: Materials Science and Engineering, Institute of Physics Publishing, https://doi.org/10.1088/1757-899X/418/1/012110

Kott M, Erz C, Heingärtner J, Groche P (2020) Controllability of temperature induced friction effects during deep drawing of car body parts with high drawing depths in series production. Procedia Manuf 47:553–560. https://doi.org/10.1016/j.promfg.2020.04.166

Nielsen CV, Arinbjarnar Ú, Ceron E, Madsen TL, Møller B, Madsen KM, Siimut K (2023) A novel ironing punch concept with adjustable tool diameter. CIRP Ann 71(1):213–216. https://doi.org/10.1016/j.cirp.2023.03.001

Lin B-T, Huang K-M, Kuo CC, Wang WT (2015) Improvement of deep drawability by using punch surfaces with microridges. J Mater Process Technol 225:275–285. https://doi.org/10.1016/j.jmatprotec.2015.06.012

Lin BT, Yang CY (2017) Applying the Taguchi method to determine the influences of a microridge punch design on the deep drawing. Int J Adv Manuf Technol 88:5–8. https://doi.org/10.1007/s00170-016-8911-y

Lin BT, Yang CY (2017) Using a punch with micro-ridges to shorten the multistage deep drawing process for stainless steels. Int J Adv Manuf Technol 88:9–12. https://doi.org/10.1007/s00170-016-8928-2

Zhang Z, Chen N, Furushima T, Li B (2018) Deformation behavior of metal foil in micro pneumatic deep drawing process. Procedia Manuf 15:1422–1428. https://doi.org/10.1016/J.PROMFG.2018.07.339

Yamaguchi R, Shimizu T, Yang M (2016) Influence of servo motion on forming limit of thin metallic foils using micro bulge test. Key Eng Mater 716:208–214. https://doi.org/10.4028/www.scientific.net/KEM.716.208

Yamaguchi R, Bai Y, Shimizu T, Yang M (2015) Effect of ultrasonic vibration on stress relaxation in micro-compression test with step motion. Mech Eng J 2(1). https://doi.org/10.1299/mej.14-00410

Hadi S (2021) Micro cup drawing without wrinkles using a bulged punch. Eng J 25(12):51–62. https://doi.org/10.4186/EJ.2021.25.12.51. A. K. Tieu, C. Lu, H. L. Yu, A. Kusmoko, A. Murdani, and D. Ginting

Tröber P, Weiss HA, Kopp T, Golle R, Volk W (2017) On the correlation between thermoelectricity and adhesive tool wear during blanking of aluminum sheets. Int J Mach Tools Manuf 118–119. https://doi.org/10.1016/j.ijmachtools.2017.03.005

Tröber P, Welm M, Weiss HA, Demmel P, Golle R, Volk W (2021) Temperature, thermoelectric current and adhesion formation during deep drawing. Wear 477:203839. https://doi.org/10.1016/j.wear.2021.203839

Welm M, Tröber P, Weiss HA, Demmel P, Golle R, Volk W (2020) Thermoelectrically based approaches to reduce adhesive wear during blanking. JOM 72(7):2525–2535. https://doi.org/10.1007/s11837-020-04191-8

Tröber P, Weiss HA, Kopp T, Golle R, Volk W (2022) Reduction of adhesive wear with use of tool coating reducing thermoelectric currents. IOP Conf Ser Mater Sci Eng 1238:012033. https://doi.org/10.1088/1757-899X/1238/1/012033

Lee R-S, Chen C-H, Gau J-T (2008) Effect of thickness to grain size ratio on drawability for micro deep drawing of AISI 304 stainless steel, in Proceedings of the 9th International Conference on Technology of Plasticity, pp. 183–188

Wang C, Wang H, Chen G, Zhu Q, Zhang G, Cui L, Zhang P (2020) Size effects affected uniaxial tensile properties and formability in rubber pad microforming process of pure nickel thin sheets. Int J Mech Sci 182. https://doi.org/10.1016/j.ijmecsci.2020.105757

Gu X, Wang X, Ma Y, Zhang H, Lu J, Wang K, Liu H (2021) Investigation on grain size effect and forming mechanism of laser shock hydraulic microforming of copper foil. Int J Adv Manuf Technol 114:1049–1064. https://doi.org/10.1007/s00170-021-06969-9

Liu Z, Zhang S, Xia D, Han Q, Wang S, Zhang X, Liu J, Wu S, Zhu E (2022) Effect of thickness on tensile properties and fracture mode of 316L stainless steel sheet, in Proceedings of SPIE, SPIE-Intl Soc Optical Eng, p. 163. https://doi.org/10.1117/12.2635174

Furushima T, Tsunezaki H, Manabe K, Alexsandrov S (2018) Fracture and surface roughening behaviors in micro metal forming. Procedia Manuf 15:1481–1486. https://doi.org/10.1016/j.promfg.2018.07.331

Weiss M, Zhang P, Pereira MP, Rolfe BF, Wilkosz DE, Hodgson PD (2021) Understanding size effects and forming limits in the micro-stamping of industrial stainless steel foils. Met (Basel) 11(1). https://doi.org/10.3390/met11010038

Sène NA, Balland P, Arrieux R, Vacher P (2013) Determination and validation of micro-forming limit diagrams for very thin materials. IntJ Mater Form 6(1):41–48. https://doi.org/10.1007/s12289-011-1068-1

Wang J, Fu MW, Ran J (2014) Analysis of size effect on flow-induced defect in micro-scaled forming process. Int J Adv Manuf Technol 73:9–12. https://doi.org/10.1007/s00170-014-5947-8

Bauer A, Mehner T, Awiszus B, Lampke T (2021) Metal foils for bipolar plates - correlation of initial grain size and forming behavior of 316L, in Forming the Future, The Mineral, Metals & Materials Society, pp. 1743–1756. https://doi.org/10.1007/978-3-030-75381-8_146

Si S, Wu Q, Mei D, Mao W, Song S, Xu L, Zuo T, Wang Y (2022) Numerical simulation and experiment of microstamping process to fabricate multi-channel of SUS304 thin sheets with different grain size. Int J Adv Manuf Technol 121:9–10. https://doi.org/10.1007/s00170-022-09776-y

Cetin ME, Cora ÖN, Sofuoglu H (2020) Micro deep drawability of the superplastic Zn-22Al alloy at a high strain rate and room temperature. J Eng Mater Technol 142. https://doi.org/10.1115/1.4044440

Tóth LS, Lapovok R, Molotnikov A, Gu C, Fundenberger J-J, Davies CHJ (2010) Texture evolution during micro-drawing of ultrafine grained copper. Mater Sci Eng A 527:4633–4640. https://doi.org/10.1016/j.msea.2010.04.011

Xu J, Li J, Zhu X, Fan G, Shan D, Guo B (2015) Microstructural evolution at micro/meso-scale in an ultrafine-grained pure aluminum processed by equal-channel angular pressing with subsequent annealing treatment. Materials 8(11):7447–7460. https://doi.org/10.3390/ma8115391

Xu J, Li J, Shi L, Shan D, Guo B (2015) Effects of temperature, strain rate and specimen size on the deformation behaviors at micro/meso-scale in ultrafine-grained pure Al. Mater Charact 109:181–188. https://doi.org/10.1016/j.matchar.2015.10.003

Molotnikov A, Lapovok R, Gu CF, Davies CHJ, Estrin Y (2012) Size effects in micro cup drawing. Mater Sci Eng A 550:312–319. https://doi.org/10.1016/j.msea.2012.04.079

Reis LM, Carvalho AP, Lee I, Wu YH, Han JK, Santala MK, Kawasaki M, Figueiredo RB (2023) Cold angular rolling process as a continuous severe plastic deformation technique. J Mater Sci 58(10):4621–4636. https://doi.org/10.1007/s10853-023-08295-9

Utsunomiya H, Hatsuda K, Sakai T, Saito Y (2004) Continuous grain refinement of aluminum strip by conshearing. Mater Sci Engineering: A 372:1–2. https://doi.org/10.1016/j.msea.2003.12.014

Klinge L, Siemers C, Kluy L, Groche P (2022) Nanostructured Ti–13Nb–13Zr for dental implant applications produced by severe plastic deformation. J Mater Res 37(16):2581–2588. https://doi.org/10.1557/s43578-022-00587-1

Dhal A, Panigrahi SK, Shunmugam MS (2018) Investigation into the micro deep drawing capabilities of a specially engineered refined aluminium alloy, MATEC Web of Conferences, vol. 190, https://doi.org/10.1051/matecconf/201819010001

Dhal A, Panigrahi SK, Shunmugam MS (2019) Achieving excellent microformability in aluminum by engineering a unique ultrafine-grained microstructure. Sci Rep 9(1). https://doi.org/10.1038/s41598-019-46957-4

An J, Wang YF, Wang QY, Cao WQ, Huang CX (2015) The effects of reducing specimen thickness on mechanical behavior of cryo-rolled ultrafine-grained copper. Mater Sci Eng A 651:1–7. https://doi.org/10.1016/j.msea.2015.10.091

Hadi S, Kiet Tieu A, Lu C, Zhu H (2013) A micro deep drawing of ARB processed aluminium foil AA1235. Int J Mater Prod Technol 47:175–187. https://doi.org/10.1504/IJMPT.2013.058973

Yu HL, Kiet Tieu A, Hadi S, Lu C, Godbole AR (2015) High strength and ductility of ultrathin laminate foils using accumulative roll bonding and asymmetric rolling. Metall Mater Trans Phys Metall Mater Sci 46(2):869–879. https://doi.org/10.1007/s11661-014-2640-3

Zhao J, Wang T, Jia F, Li Z, Zhou C, Huang Q, Jiang Z (2021) Experimental investigation on micro deep drawing of stainless steel foils with different microstructural characteristics. Chin J Mech Eng (English Edition) 34(1). https://doi.org/10.1186/s10033-021-00556-5

Zhao J, Jiang Z, Wang Z, Sang S, Dobrzański LA, Yang M, Ma X, Wang Y (2022) An analysis of micro deep drawing of ferritic stainless steel 430 using crystal plasticity finite element method. J Mater Res Technol 20:2247–2261. https://doi.org/10.1016/J.JMRT.2022.07.105

Li L, Qi YY, Ma XG, Jiang ZY, Manabe K, Lee CS, Zhao JW (2022) A study of the formability of stainless steel foils during micro deep drawing. IOP Conf Ser Mater Sci Eng 1270(1). https://doi.org/10.1088/1757-899X/1270/1/012030

Tekkaya AE, Groche P, Kinsey BL, Wang ZG (2023) Stress superposition in metal forming. CIRP Ann 72(2). https://doi.org/10.1016/j.cirp.2023.04.090

Sato H, Manabe K, Ito K, Wei D, Jiang Z (2015) Development of servo-type micro-hydromechanical deep-drawing apparatus and micro deep-drawing experiments of circular cups. J Mater Process Technol 224:233–239. https://doi.org/10.1016/j.jmatprotec.2015.05.014

Koga N, Asaka M, Junlapen K (2007) Deep-drawing and ironing of 1050 aluminum sheets loaded with vibration using NC servo press machine. J Japan Inst Light Met 57(6):240–244. https://doi.org/10.2464/jilm.57.240

Seo YH, Park CJ, Kim BH, Lee HJ, Lee NK (2012) Development of audio frequency vibration microforming system. Int J Precis Eng Manuf 13(5):789–794. https://doi.org/10.1007/s12541-012-0104-5

Shao G, Li H, Zhan M (2021) A review on ultrasonic-assisted forming: mechanism, model, and process. Chin J Mech Eng 34(1). https://doi.org/10.1186/s10033-021-00612-0

Huang YM, Wu YS, Huang JY (2014) The influence of ultrasonic vibration-assisted micro-deep drawing process. Int J Adv Manuf Technol 71:5–8. https://doi.org/10.1007/s00170-013-5553-1

Bai Y, Yang M (2015) Deformation analysis of brass in micro compression test with presence of ultrasonic vibration. Int J Precis Eng Manuf 16(4):685–691. https://doi.org/10.1007/s12541-015-0091-4

Zha CL, Chen W (2019) Theories and experiments on effects of acoustic energy field in micro-square cup drawing. Int J Adv Manuf Technol 104:9–12. https://doi.org/10.1007/s00170-019-04338-1

Ikeuchi K, Wake Y, Wake T, Ikuta S, Shikazono N, Yanagimoti J (2011) Springback of Ultra Thin Stainless Steel Sheet after Cold and Warm Forming, in Proceedings of the 10th International Conference on Technology of Plasticity, G. Hirt and A. E. Tekkaya, Eds., Aachen, Germany: Wiley-VCH Verlag GmbH & Co. KGaA. Weinheim, pp. 698–701

Aoyama T, Shimizu T, Zheng Q, Yang M (2014) Effect of heating on springback in heat assisted microbending. Adv Mat Res 939:409–414. https://doi.org/10.4028/www.scientific.net/AMR.939.409

Jiang Z, Zhao J, Lu H, Wei D, Manabe K, Zhao X, Zhang X, Wu D (2017) Influences of temperature and grain size on the material deformability in microforming process. IntJ Mater Form 10(5):753–764. https://doi.org/10.1007/s12289-016-1317-4

Eichenhüller B, Egerer E, Engel U (2007) Microforming at elevated temperature - forming and material behaviour. Int J Adv Manuf Technol 33:1–2. https://doi.org/10.1007/s00170-006-0731-z

Zheng Q, Shimizu T, Yang M (2015) Numerical analysis of temperature distribution and its optimization for thin foils in micro deep drawing assisted by resistance heating. Steel Res Int 86(8):869–876. https://doi.org/10.1002/srin.201400574

Ambrogio G, Filice L, Palumbo G, Pinto S (2005) Prediction of formability extension in deep drawing when superimposing a thermal gradient. J Mater Process Technol 162–163. https://doi.org/10.1016/j.jmatprotec.2005.02.179

Erhardt R, Schepp F, Schmoeckel D (1999) Micro forming with local part heating by laser irradiation in transparent tools, in Proceedings of the SheMet ’99, pp. 497–504

Bayer A, Gillner A, Groche P, Erhardt R (2003) Laser-assisted forming of metallic micro-parts, in Fourth International Symposium on Laser Precision Microfabrication, SPIE, pp. 157–162. https://doi.org/10.1117/12.541079

Magargee J, Morestin F, Cao J (2013) Characterization of flow stress for commercially pure titanium subjected to electrically assisted deformation. J Eng Mater Technol 135(4). https://doi.org/10.1115/1.4024394

Perkins TA, Kronenberger TJ, Roth JT (2007) Metallic forging using electrical flow as an alternative to warm/hot working. J Manuf Sci Eng 129(1):84–94. https://doi.org/10.1115/1.2386164

Wang X, Egea AJS, Xu J, Meng X, Wang Z, Shan D, Guo B, Cao J (2018) Current-induced ductility enhancement of a magnesium alloy AZ31 in uniaxial micro-tension below 373 K. Materials 12(1). https://doi.org/10.3390/ma12010111

Bao J, Bai J, Lv S, Shan D, Guo B, Xu J (2020) Interactive effects of specimen size and current density on tribological behavior of electrically-assisted micro-forming in TC4 titanium alloy. Tribol Int 151. https://doi.org/10.1016/j.triboint.2020.106457

Xie H, Dong X, Ai Z, Wang Q, Peng F, Liu K, Chen F, Wang. J (2016) Experimental investigation on electrically assisted cylindrical deep drawing of AZ31B magnesium alloy sheet. Int J Adv Manuf Technol 86:1–4. https://doi.org/10.1007/s00170-015-8246-0

Hu Z, Huferath-Von Luepke S, Von Kopylow C, Vollertsen F (2010) Characteristic of wear behavior of micro deep drawing tools. AIP Conf Proc 1315:335–340. https://doi.org/10.1063/1.3552464

Moghadam M, Suleiman MH, Christiansen P, Bay N (2017) Acoustic emission monitoring of the bending under tension test. Procedia Eng 207:1421–1426. https://doi.org/10.1016/j.proeng.2017.10.907

Moghadam M, Nielsen CV, Christiansen P, Bay N (2018) Tool condition monitoring in strip reduction testing using acoustic emission, in 8th International Seminar on Precision Forging

Tröber P, Demmel P, Hoffmann H, Golle R, Volk W (2017) On the influence of Seebeck coefficients on adhesive tool wear during sheet metal processing. CIRP Ann Manuf Technol 66:293–296. https://doi.org/10.1016/j.cirp.2017.04.116

Groche P, Wu Y (2019) Inline observation of tool wear in deep drawing with thermoelectric and optical measurements. CIRP Ann Manuf Technol 68:567–570. https://doi.org/10.1016/j.cirp.2019.04.034

Arinbjarnar Ú, Moske J, Nielsen CV (2024) Evaluation of in-line monitoring of micro-forming tribo-systems applying U-bending test principle. Unpublished

Huferath S, von Luepke P, Huke C, von Kopylow, Bergmann RB (2012) Wear recording at micro deep drawing tools with comparative digital holography. J Eur Opt Soc 7. https://doi.org/10.2971/jeos.2012.12041

Seven J, Heinrich L, Flosky H (2018) Inline tool wear measurement in lateral micro upsetting, in MATEC Web of Conferences, EDP Sciences, https://doi.org/10.1051/matecconf/201819015009

Molitor DA, Kubik C, Hetfleisch RH, Groche P (2022) Workpiece image-based tool wear classification in blanking processes using deep convolutional neural networks. Prod Eng Res Devel 1–12. https://doi.org/10.1007/s11740-022-01113-2

Agour M, Huke P, Kopylow Cv, Falldorf C, Rastogi PK, Hack E (2010) Shape measurement by means of phase retrieval using a spatial light modulator. AIP Conf Proc 1236:265–270. https://doi.org/10.1063/1.3426125

Wang N, Kopylow CV, Falldorf C (2010) Rapid shape measurement of micro deep drawing parts by means of digital holographic contouring, in Proceedings of the 36th International MATADOR Conference, pp. 45–48. https://doi.org/10.1007/978-1-84996-432-6_10

Simic A, Falldorf C, Bergmann RB (2016) Internal inspection of micro deep drawing parts using digital holography. in Digital Holography and three-dimensional imaging 2016. Optica Publishing Group, Heidelberg, Germany. doi: https://doi.org/10.1364/DH.2016.DW1H.3.

Simic A, Freiheit H, Agour M, Falldorf C, Bergmann RB (2017) In-line quality control of micro parts using digital holography, in Holography: Advances and Modern Trends V, SPIE, https://doi.org/10.1117/12.2265780

Agour M, Falldorf C, Bergmann RB (2018) Spatial multiplexing and autofocus in holographic contouring for inspection of micro-parts. Opt Express 26(22). https://doi.org/10.1364/oe.26.028576

Costache EM, Nanu N, Chirita B, Brabie G (2013) Prediction and prevention of material cracking in the case of micro or milli drawn parts made from aluminium foils. Int J Mech Sci 69:125–140. https://doi.org/10.1016/j.ijmecsci.2013.02.001

Brabie G, Costache EM, Nanu N, Chirita B (2013) Prediction and minimisation of sheet thickness variation during deep drawing of micro/milli parts. Int J Mech Sci 68:277–290. https://doi.org/10.1016/j.ijmecsci.2013.01.028

Hu Z, Vollertsen F (2011) Investigation on the optimisation of the blank shape for micro deep drawing of rectangular parts. Steel Res Int, pp. 974–978

Mahmood ZH, Irthiea IK, Ahmed AK (2020) Optimization of initial blank shape for flexible micro deep drawing of square parts. Mater Today Proc 20:555–559. https://doi.org/10.1016/j.matpr.2019.09.188

Wang J, Fu MW, Ran J (2014) Analysis of the size effect on springback behavior in micro-scaled U-bending process of sheet metals. Adv Eng Mater 16(4):421–432. https://doi.org/10.1002/adem.201300275

Luo L, Jiang Z, Wei D, Manabe K, Zhao X, Wu D, Furushima T (2016) Effects of surface roughness on micro deep drawing of circular cups with consideration of size effects. Finite Elem Anal Des 111:46–55. https://doi.org/10.1016/j.finel.2015.11.005

Furushima T, Nakayama T, Sasaki K (2019) A new theoretical model of material inhomogeneity for prediction of surface roughening in micro metal forming. CIRP Ann 68(1):257–260. https://doi.org/10.1016/j.cirp.2019.04.057

Wielage H, Hu Z, Vollertsen F (2012) Fracture behavior of thin foils. J Mater Process Technol 212(3):685–688. https://doi.org/10.1016/j.jmatprotec.2011.10.022

Guo N, Wang J, Sun CY, Zhang YF, Fu MW (2020) Analysis of size dependent earing evolution in micro deep drawing of TWIP steel by using crystal plasticity modeling. Int J Mech Sci 165. https://doi.org/10.1016/j.ijmecsci.2019.105200

Funding

This study was funded by Independent Research Fund Denmark, grant number DFF – 0136-00159B.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arinbjarnar, Ú., Schumann, P., Moske, J. et al. A review of methods and effects for improving production robustness in industrial micro-deep drawing. Int J Mater Form 17, 31 (2024). https://doi.org/10.1007/s12289-024-01832-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-024-01832-0